Container crane with double main trolleys

A technology for container cranes and trolleys, which is applied to cranes, trolleys, transportation and packaging, etc., can solve problems such as restricting the efficiency of loading and unloading operations of large container ships, and achieve easy remote control operation and automatic control, high utilization rate, and improved operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

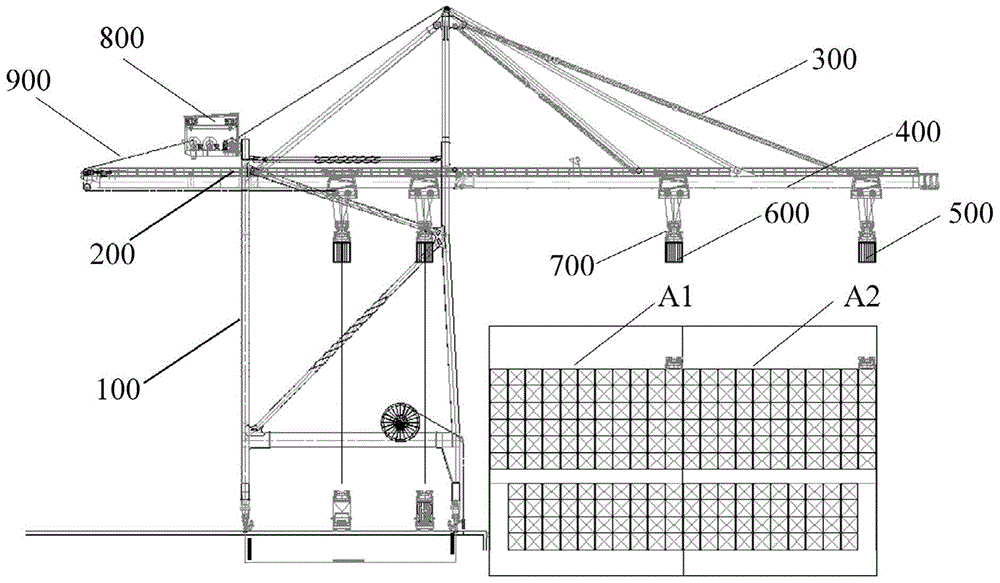

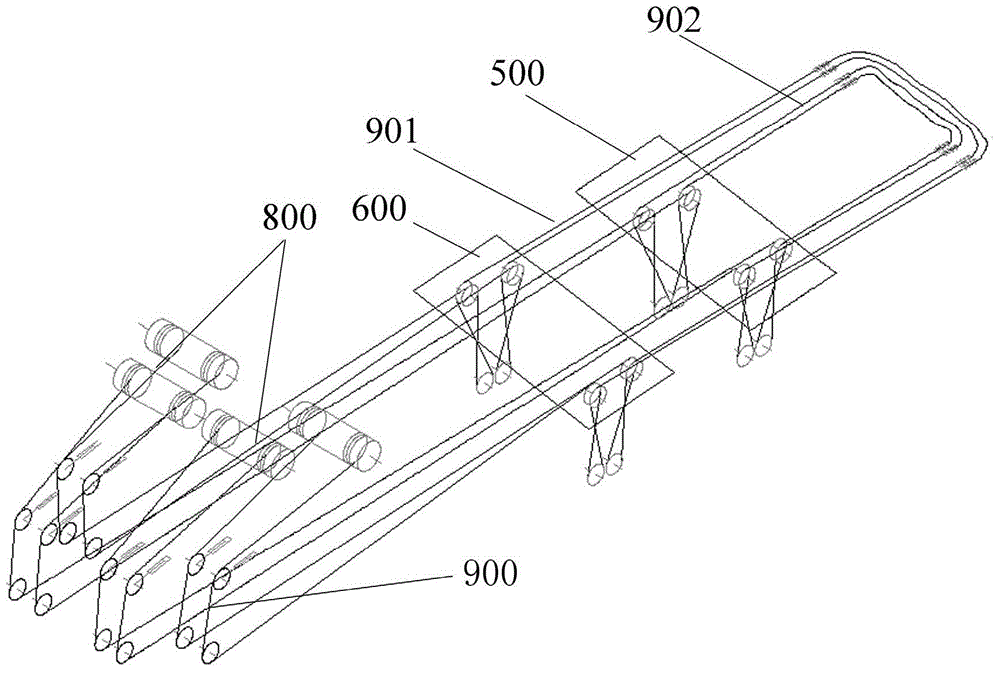

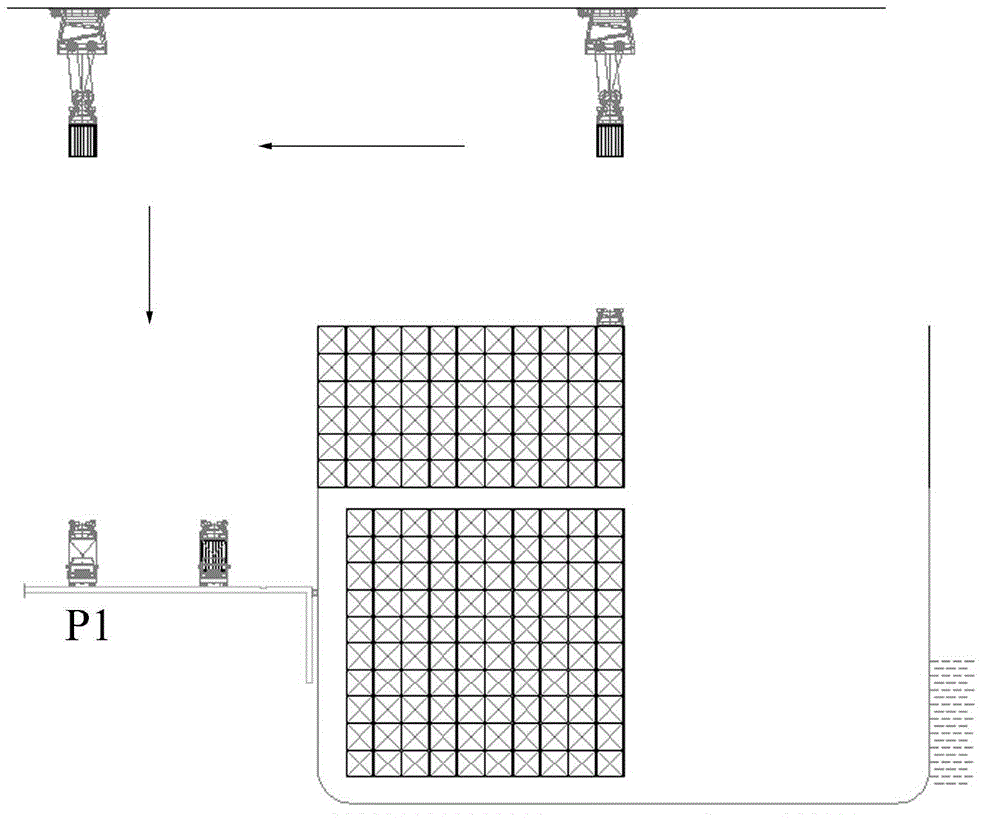

[0026] figure 1 A schematic diagram showing a container crane with double main trolleys according to an embodiment of the present invention, which includes a door frame 100, front and rear girders 200, a tie rod system 300, a power supply system 400, a seaside main trolley 500, a landside main trolley 600, and a spreader System 700, hoisting system 800, hoisting wire rope traction system 900, and the control system for controlling the above systems, wherein: the front and rear beams 200 are located on the upper part of the door frame 100; the tie rod system 300 is connected between the front and rear beams 200 and the door frame 100; the power supply system 400 is located on the front and rear girders 200 and is used to supply power to the main trolley; the sea-side main trolley 500 and the land-side main trolley 600 are connected to the front and rear girders 200, and the sea-side main trolley 500 is responsible for transporting the containers in the operation area A2 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com