Waste alkali solution recycling method

A technology for waste lye and aqueous solution, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of inability to recover and recycle waste lye, and achieve energy saving. The effect of emission reduction, environmental protection and added value increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

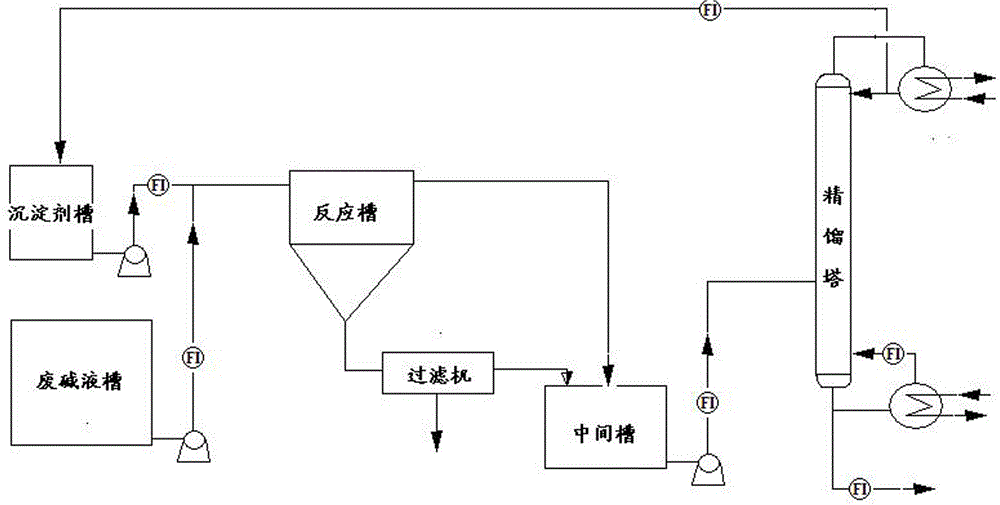

Image

Examples

Embodiment 1

[0021] 1. Pass the waste viscose fiber lye (containing about 4% hemicellulose and 20% sodium hydroxide) into the precipitation reactor, add hemicellulose precipitant, mix well, and let it stand for a period of time. After the solution is obviously stratified, the supernatant liquid is passed into the intermediate tank, and the supernatant liquid is removed to obtain a hemicellulose slurry.

[0022] 2. Put the hemicellulose slurry into the solid-liquid separator to separate the hemicellulose, wash and dry the solid hemicellulose, weigh and calculate the hemicellulose removal rate, the results are shown in Table 1. The filtrate and washing liquid are aqueous solutions containing precipitant and sodium hydroxide, which are passed into the intermediate tank and combined with the supernatant.

[0023] 3. Pass the aqueous solution containing precipitating agent and sodium hydroxide into the rectification tower, and realize the separation of lye and precipitating agent in the rectificati...

Embodiment 2

[0028] The above hemicellulose precipitation agent is an aqueous solution of methanol and polyferric sulfate in a ratio of 1000:1 parts by weight.

[0029] The steps are the same as in Example 1. The results are shown in Table 2.

[0030] Table 2 Results of removing hemicellulose by methanol precipitation

[0031] Waste lye: precipitation agent Hemicellulose removal rate / % Recovery rate of precipitation agent / % Recovery rate of lye / % 1:13599.8100 1:1.54599.6100 1:26099.5100 1:2.5 7599.5100 1:38599.5100 1:48599.5100 1:57599.6100

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com