Manufacturing method of artificial flute diaphragm

A production method and technology of flute membranes, which are applied in the field of artificial flute membranes, can solve the problems of the time of the flute membranes and individual differences that cannot be industrialized, and achieve the effects of improving weather resistance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

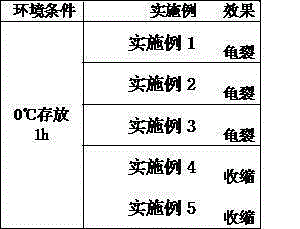

Examples

Embodiment 1

[0008] Example 1: (1), in parts by weight, 13 parts of bamboo leaf flavonoids, 6 parts of bamboo juice, 0.3 parts of sodium lauryl sulfonate and 5 parts of paraffin wax were homogenized at high speed for 5 minutes, and then added 100 parts (2) Add 4 parts of polypropylene and 0.05 parts of dilauryl thiodipropionate to the mixed solution in parts by weight, stir evenly, and cool to room temperature to form a premix ; (3) Put the premixed material into the granulator to extrude and granulate, and control the granulation temperature to 120°C; (4) Send the granulated granules to the film-making machine to make a film, and cut the film The artificial flute membrane can be obtained by making it into a suitable size.

Embodiment 2

[0009] Example 2: (1), in parts by weight, 31 parts of bamboo leaf flavonoids, 12 parts of bamboo juice, 2.4 parts of sodium lauryl sulfonate and 17 parts of paraffin were homogenized at high speed for 10 minutes, and then 120 parts were added thereto Heat deionized water at 120°C for 3 hours; (2) Add 7 parts of polypropylene and 0.4 parts of dilauryl thiodipropionate to the mixed solution in parts by weight, stir evenly, and cool to room temperature to form a premix ; (3), put the premix into the granulator to extrude and granulate, and control the granulation temperature to 200°C; (4), send the granulated granules to the film making machine to make a film, and cut the film The artificial flute membrane can be obtained by making it into a suitable size.

Embodiment 3

[0010] Example 3: (1), in parts by weight, 25 parts of bamboo leaf flavonoids, 8 parts of bamboo juice, 1.6 parts of sodium lauryl sulfonate and 11 parts of paraffin wax were homogenized at high speed for 7 minutes, and then 110 parts were added thereto Heat deionized water at 110°C for 2 hours; (2) Add 5 parts of polypropylene and 0.25 parts of dilauryl thiodipropionate to the mixed solution in parts by weight, stir evenly, and cool to room temperature to form a premix (3) Put the premixed material into the granulator to extrude and granulate, and control the granulation temperature to 160°C; (4) Send the granulated granules to the film-making machine to make a film, and cut the film The artificial flute membrane can be obtained by making it into a suitable size.

[0011] Example Thermal stability (min) transparency Air tightness (m / s.Pa) Tear resistance (kN.m) Example 1 3.1 transparent 2.9 30 Example 2 2.8 transparent 2.8 32 Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com