Automatic material collecting device for sewing machine

An automatic material receiving and sewing machine technology, applied in the field of sewing processing, can solve the problems of inconsistent cloth quantity, waste of manpower, material resources, and cloth corner wrinkles, etc., to achieve the effects of high production efficiency, improved material receiving efficiency, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

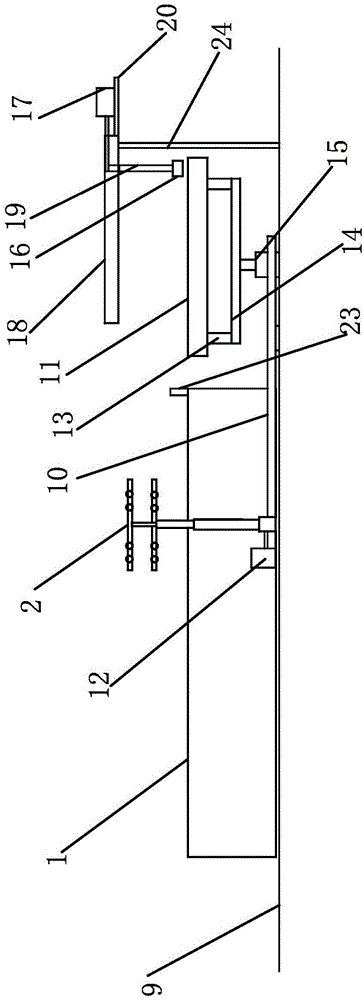

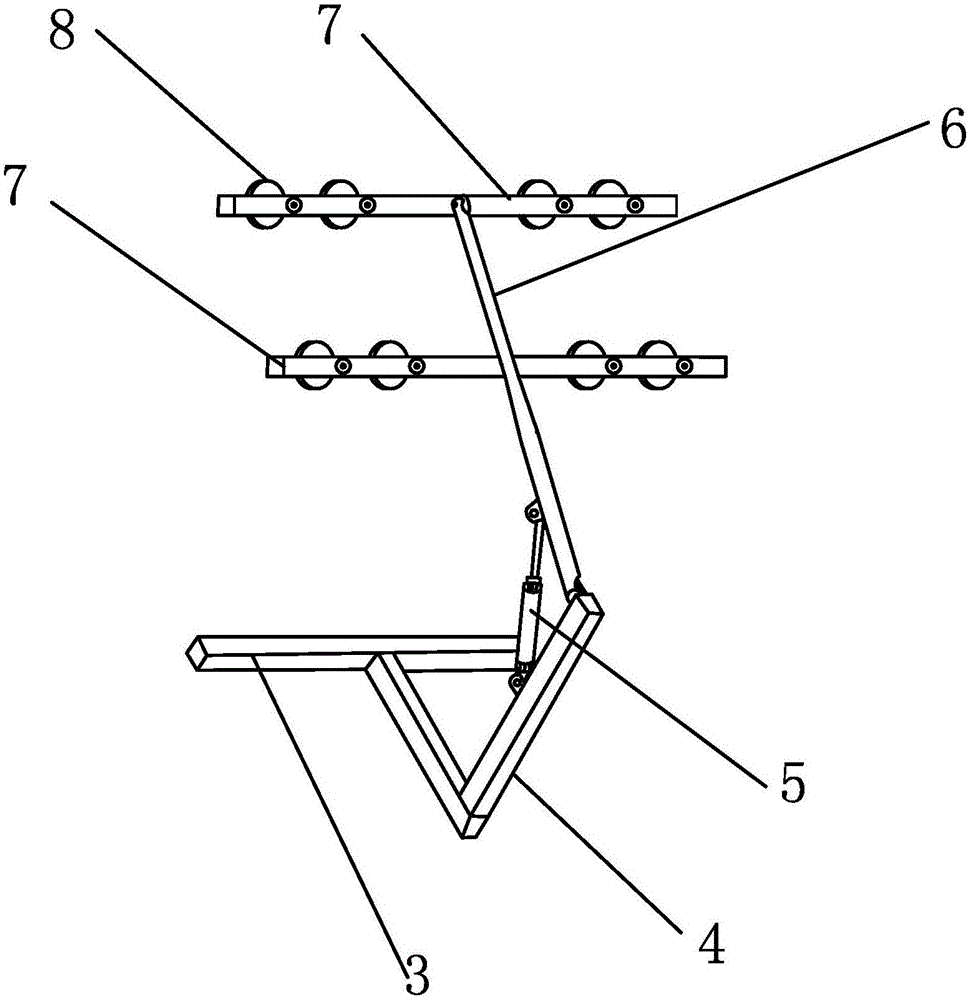

[0029] Such as Figure 1-3 As shown, the technical solution of the present invention is: an automatic material receiving device of a sewing machine, comprising a conveying platform 1, and a suction mechanism 2 is symmetrically arranged on both sides of the right end of the conveying platform 1,

[0030] The suction mechanism 2 includes a connecting rod 3 and an L-shaped frame 4 vertically connected to the connecting rod 3. One end of the first cylinder 5 is hinged on the inside of the vertical beam of the L-shaped frame 4. The piston of the first cylinder 5 The rod end is hinged on the middle part of the moving arm 6, and one end of the moving arm 6 is movably hinged on the end of the vertical beam of the L-shaped frame 4, and two groups of retrieving mechanisms are vertically articulated on the moving arm 6, and the described retrieving mechanism It includes a flat rod 7 and several vacuum suction nozzles 8, and several vacuum suction nozzles 8 are evenly arranged and distrib...

Embodiment 2

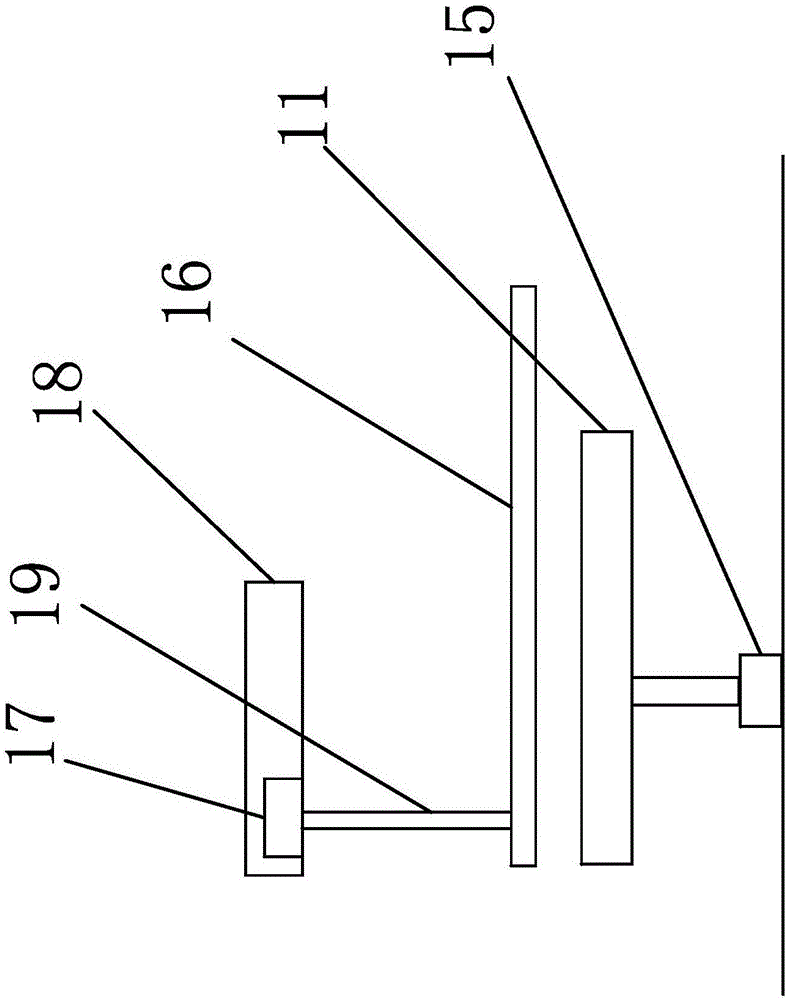

[0035] The inner cavity of the moving arm 6 is hollow, and one end is open, and the opening end is sleeved on the adjusting rod 21, and a plurality of fixing holes 22 are arranged on the corresponding positions on the moving arm 6 and the adjusting rod 21. 21. The movable arm 6 is hinged with a reclaiming mechanism.

[0036] A baffle 23 is provided on the right side of the delivery platform 1 to prevent the cloth from being passed out from the right end of the delivery platform 1 before it is sucked up by the suction mechanism 2. The support plate 18 is fixed on the On the workbench 9, the left end of the transfer platform 1 is connected to the discharge port of the sewing machine, and the others are the same as in the first embodiment.

[0037] Among them, the time to send a signal to the second cylinder 12 after the material detection sensor sends a signal to the first cylinder 5 is set in advance; the time to send a signal to the moving cylinder 15 after the position sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com