Continuous observation method and continuous observation device for dam deformation based on MEMS array

A technology of observation device and dam, applied in the direction of measurement device, instrument, etc., can solve the problem of lack of effective observation methods for dam body deformation, and achieve the effect of saving manpower and material cost, good effect and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

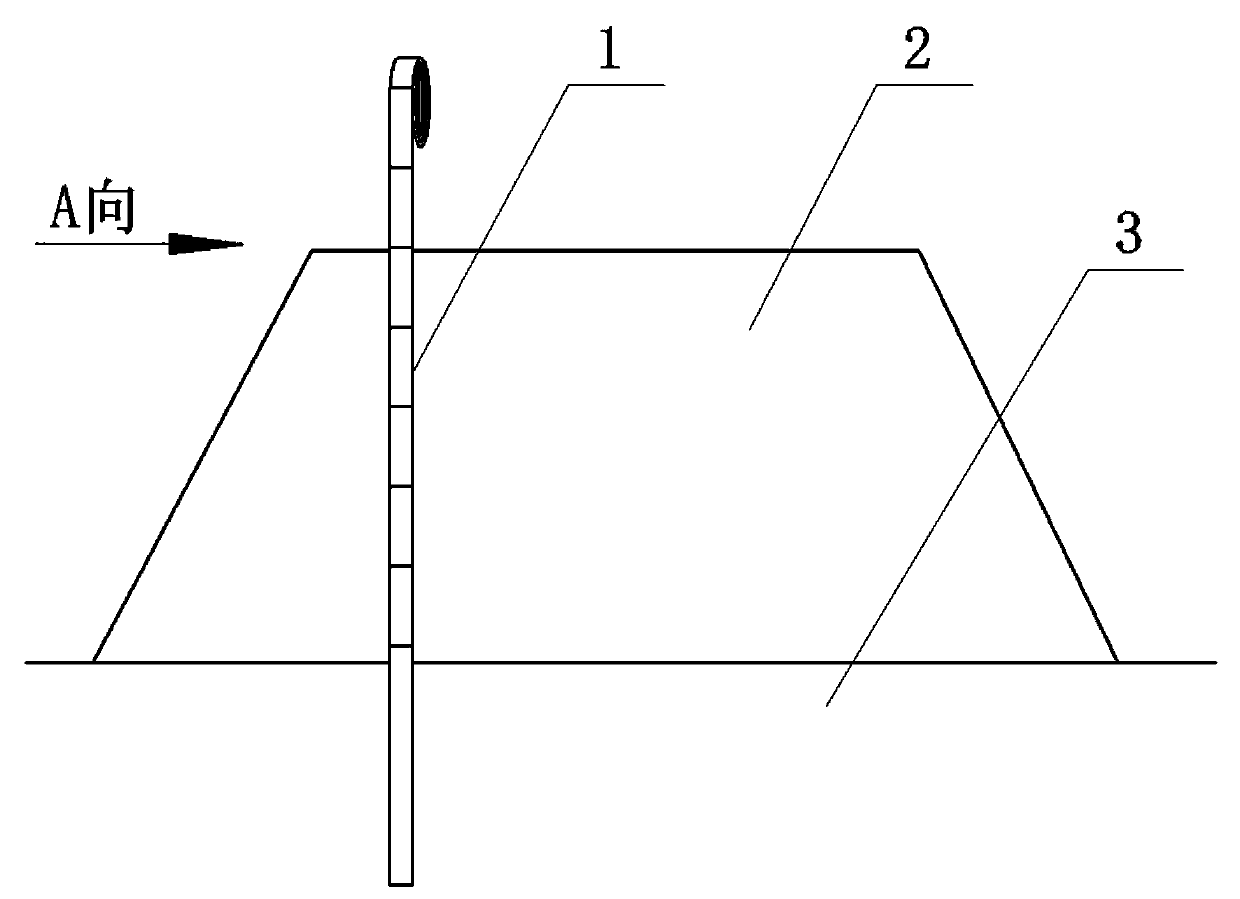

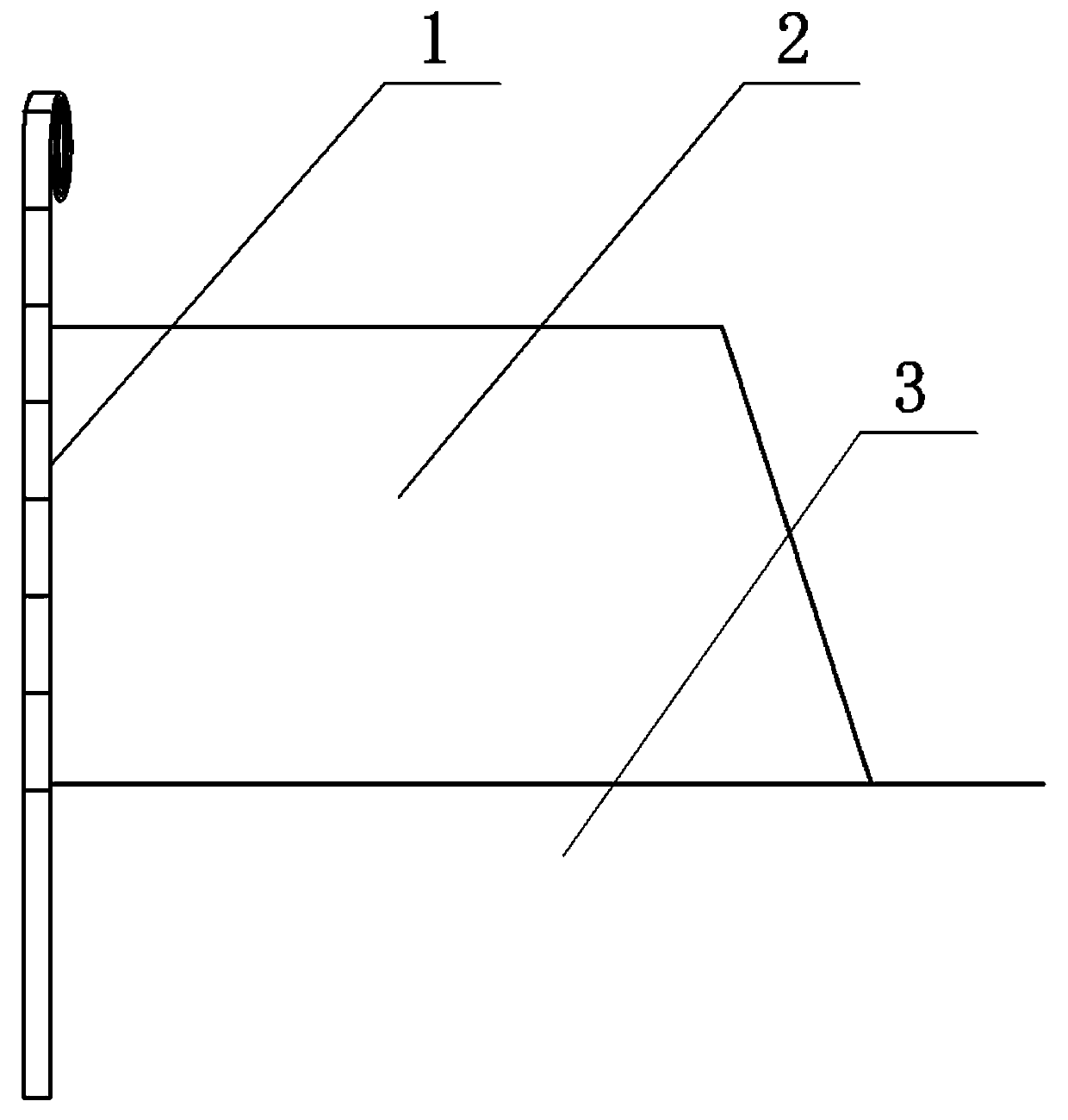

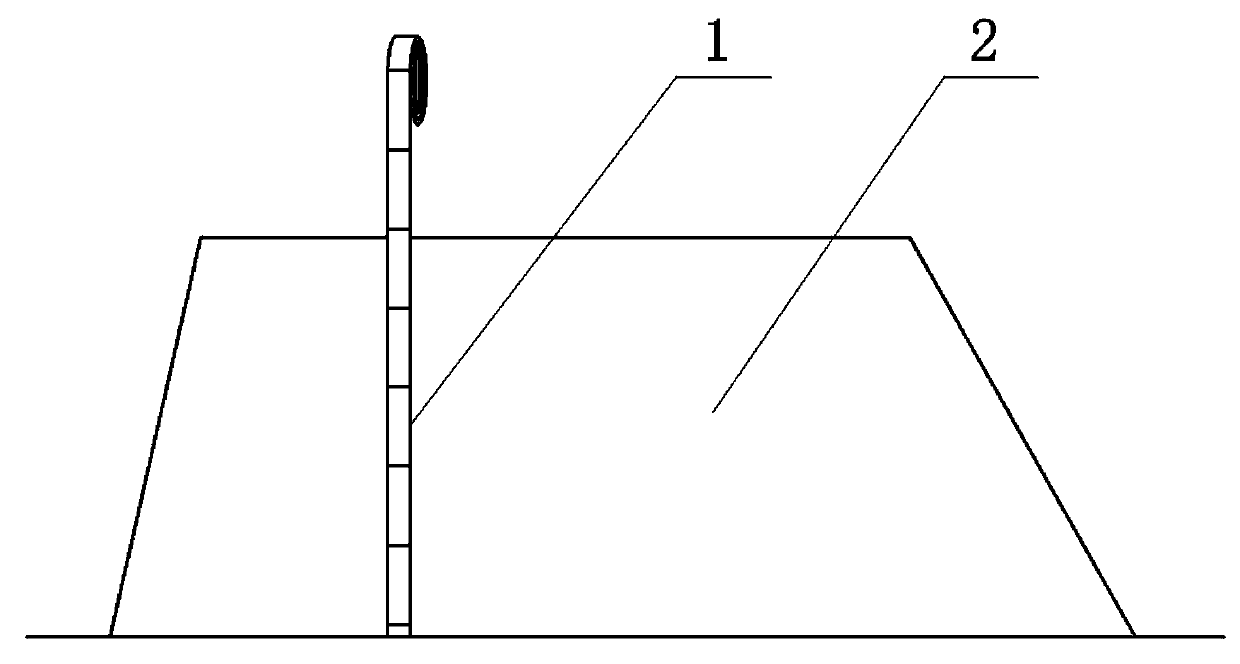

[0025] Embodiment 1: A MEMS array-based continuous observation device for dam deformation during construction, see Image 6 with Figure 8 , the embedded MEMS sensors 12 are distributed in the strip (or columnar) carrier 11, and each MEMS sensor 12 is connected to the processor 15 through the data line 13, and the processor 15 transmits to the monitoring system through wired or wireless means. The belt-shaped (or columnar) carrier 11 is made of flexible anti-corrosion and tensile materials. According to the position changes of the sensors at different positions and the angle changes between adjacent position sensors, it is converted into a visible state or a monitorable state, so as to determine the degree of deformation of the dam body 2 .

Embodiment 2

[0026] Example 2: see Figure 7 , is a further supplement to Embodiment 1. If the length of the strip (or columnar) carrier 11 is insufficient, adjacent strip (or columnar) carriers 11 can be connected through the data line plug 16 and the data line slot 17 fixed.

Embodiment 3

[0027] Embodiment 3: The first MEMS array-based method for continuous observation of dam deformation during construction is a foundation monitoring method. A MEMS array-based continuous observation device for dam deformation during construction is buried at a certain depth of the foundation by drilling holes, and a certain point in the foundation is set as a reference point to start the layout for observing the deformation of the foundation. Among them, the MEMS array-based continuous observation device for dam deformation during the construction period is distributed with embedded MEMS sensors 12 in the strip (or columnar) carrier 11, and each MEMS sensor 12 is connected to the processor 15 through the data line 13, and the processor 15 passes Wired or wireless transmission to the monitoring system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com