Underwater metal structure defect detecting probe based on alternating current electromagnetic field

An AC electromagnetic field, metal structure technology, applied in the direction of material magnetic variables, etc., can solve the problems of difficult metal structure defect detection, signal attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

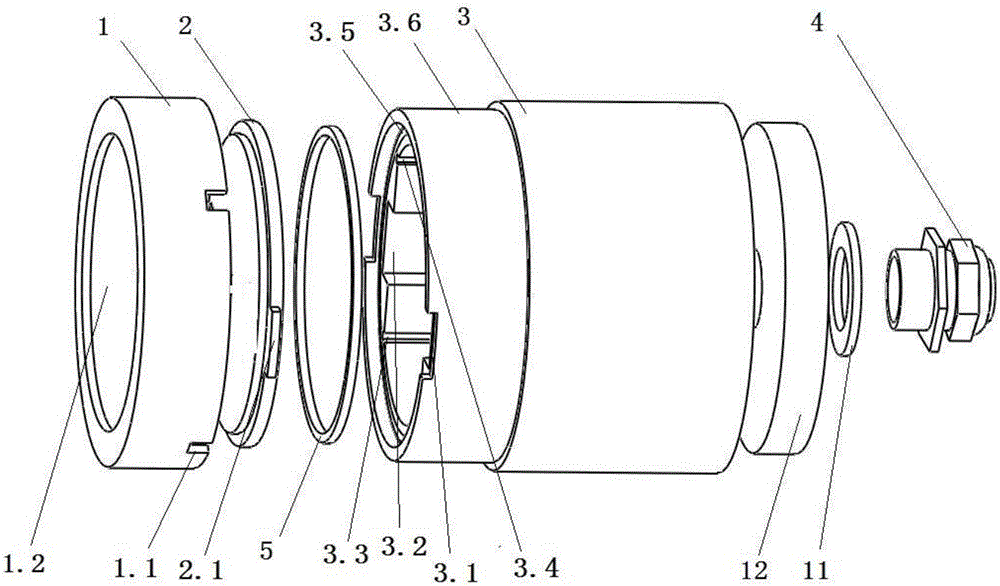

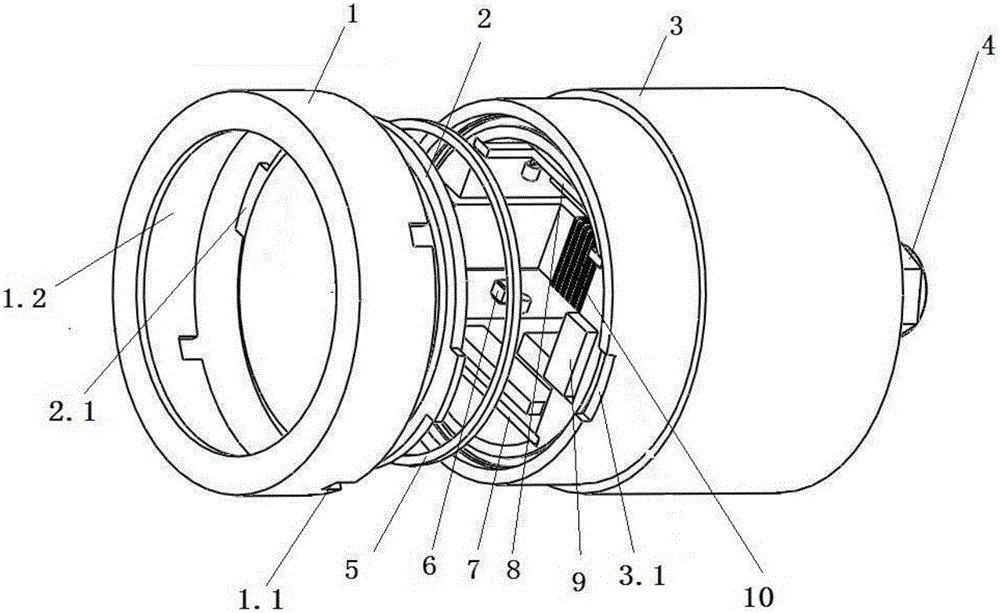

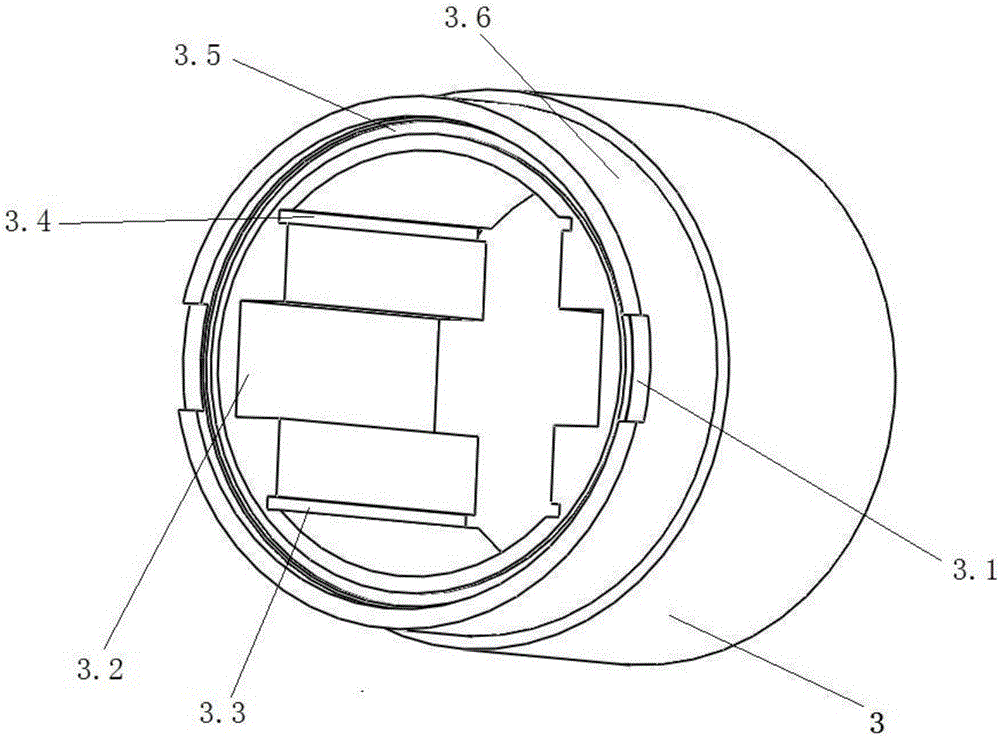

[0012] combined with Figure 1-5 , to further describe the present invention:

[0013] The present invention mainly consists of a gland 1, a bottom cover 2, a cylinder body 3, a sealing joint 4, an O-ring 5, a detection coil 6, an excitation circuit 7, a conditioning circuit 8, a U-shaped magnetic core 9, an excitation coil 10, and a gasket 11 It is composed of a top cover 12, the gland 1 is a hollow ring structure, the outside of the gland is provided with four elastic openings 1.1, and the interior is provided with internal threads 1.2, the bottom cover 2 is made of plexiglass material, and the edge of the bottom cover 2 is provided with There are two limit blocks 2.1, the cylinder 3 is 316L stainless steel resistant to seawater corrosion, the cylinder 3 is provided with a limit groove 3.1, a rectangular groove 3.2, a card groove A 3.3, a card groove B 3.4 and a sealing groove 3.5, the cylinder The bottom of the body 3 is provided with an external thread 3.6, the O-ring 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com