Double-point elastic supporting cylinder vortex induced vibration fluid kinetic energy conversion device

A technology of elastic support and vortex-induced vibration, which is applied in the direction of engines, wind power generation, engine components, etc., can solve problems such as low buoyancy efficiency, inflexible power generation methods, and narrow power generation frequency band, and achieve high support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

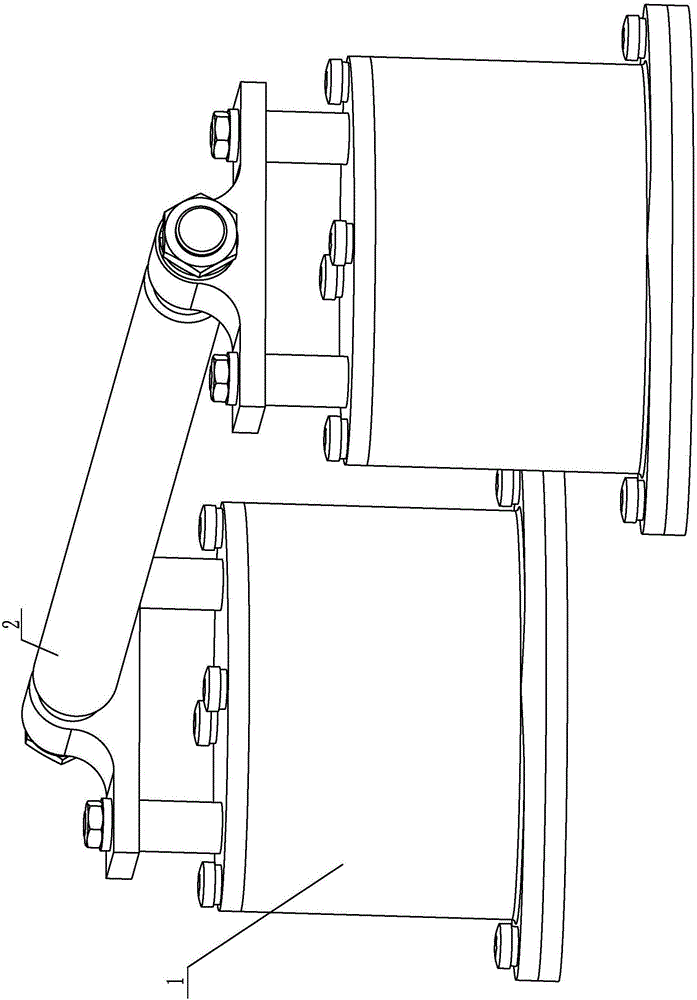

[0016] Specific implementation mode one: combine Figure 1-Figure 5 Explain that the two-point elastically supported cylindrical vortex-induced vibration fluid kinetic energy conversion device of this embodiment includes an excitation beam 2 and two exciters 1; two excitation generators 1 are arranged side by side at both ends of the excitation beam 2;

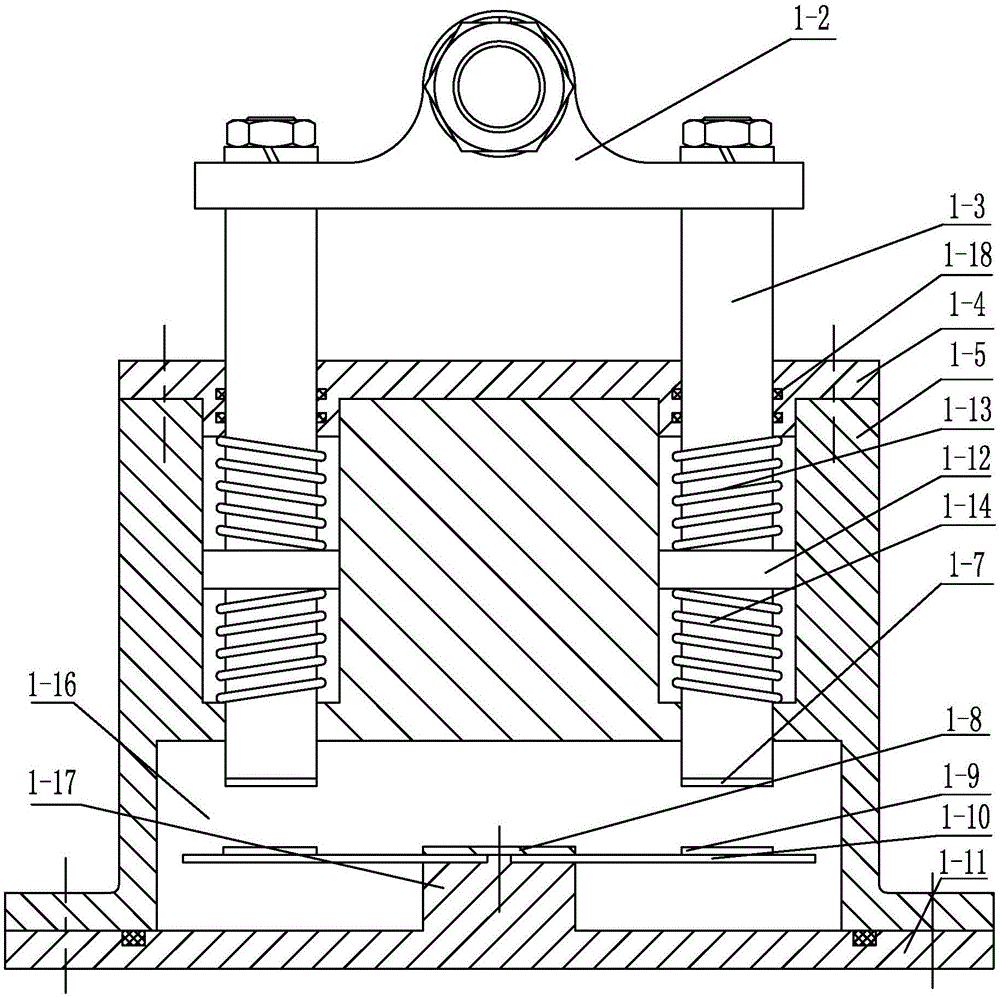

[0017] Each excitation generator 1 comprises connecting plate 1-2, sealing cover 1-4, guide column 1-5, base 1-11, two vibration columns 1-3, two excitation permanent magnets 1-7, two A vibrated permanent magnet 1-9, two cantilever beam piezoelectric buoyancy devices 1-10 and four springs; the four springs are respectively two upper springs 1-13 and two lower springs 1-14; guide column 1-1 5 is arranged on the base 1-11, a cavity 1-16 is formed between the lower end surface of the guide column 1-5 and the upper end surface of the base 1-11; 2 connections;

[0018] Two vibrating columns 1-3 are arranged side by side on the lo...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 2 and Figure 5 To illustrate, the raised portion 1-12 of this embodiment is an annular raised portion. With such arrangement, the structure is simple, the design is reasonable, and the operation is stable and reliable. Others are the same as in the first embodiment.

specific Embodiment approach 3

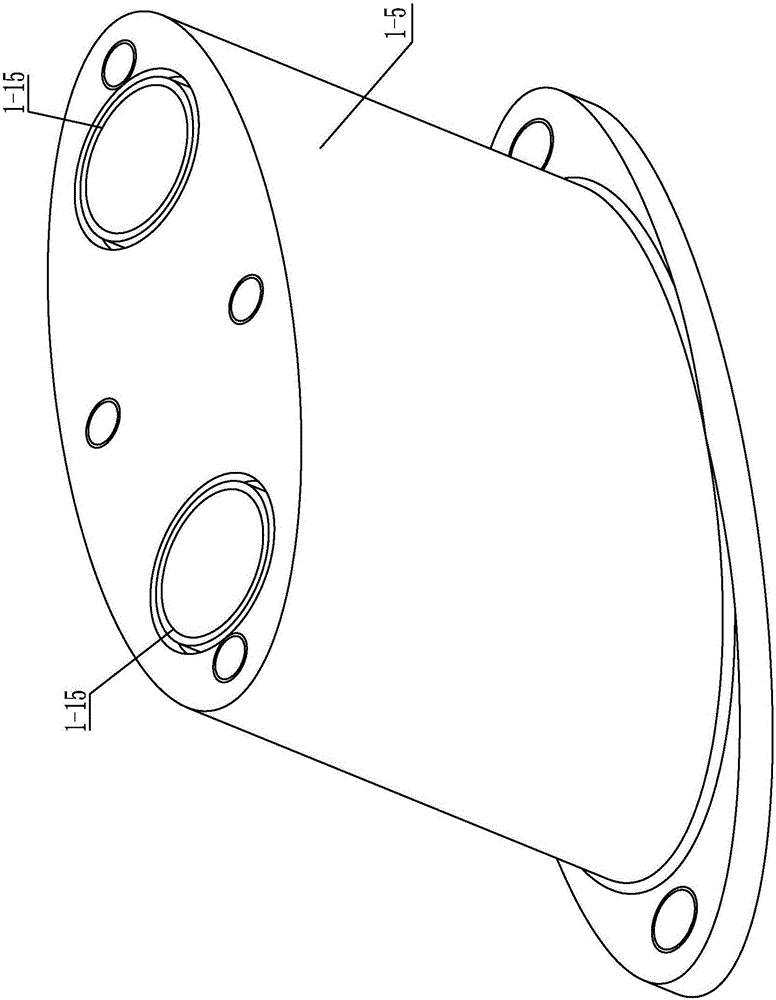

[0021] Specific implementation mode three: combination Figure 1-Figure 3 Illustrate, the cross-section of the guide post 1-5 of the present embodiment is ellipse, two through holes 1-15 are offered on the major axis of guide post 1-5, and the two cantilever beam piezoelectric buoyancy devices 1-10 The longitudinal direction of the piezoelectric sheet is parallel to the major axis direction of the guide posts 1-5. In such a setting, the excitation beam and the connecting plate are vertically arranged, and the support stability is higher. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com