flow formed brake disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

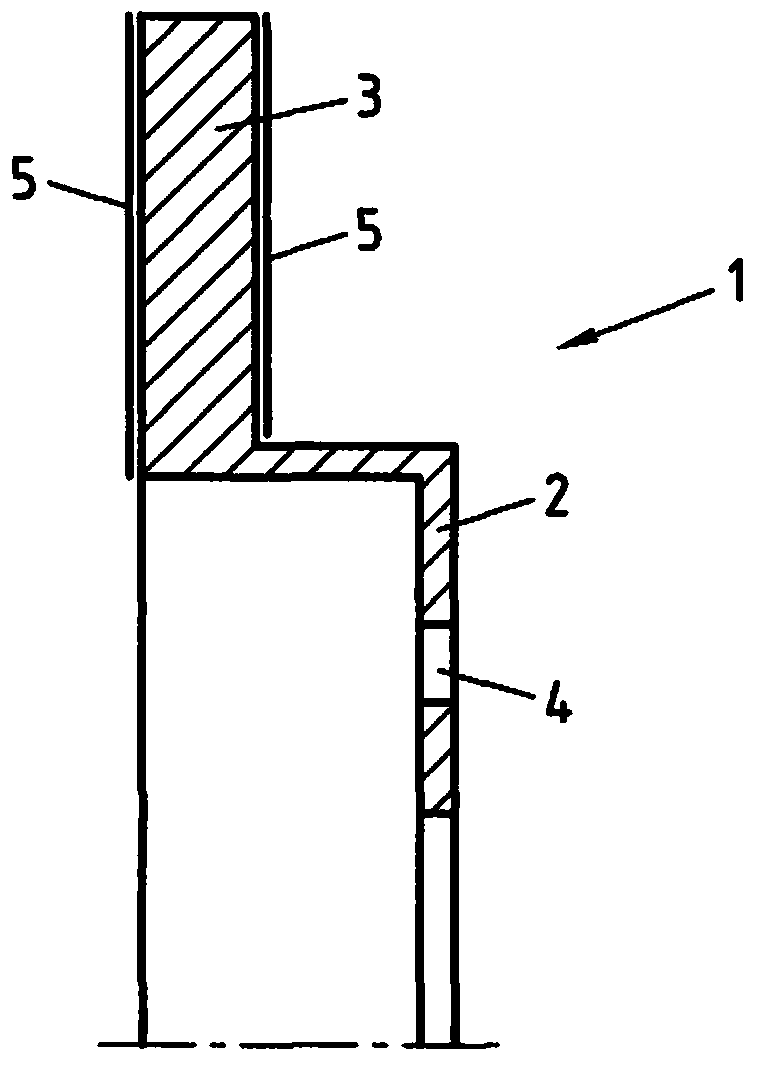

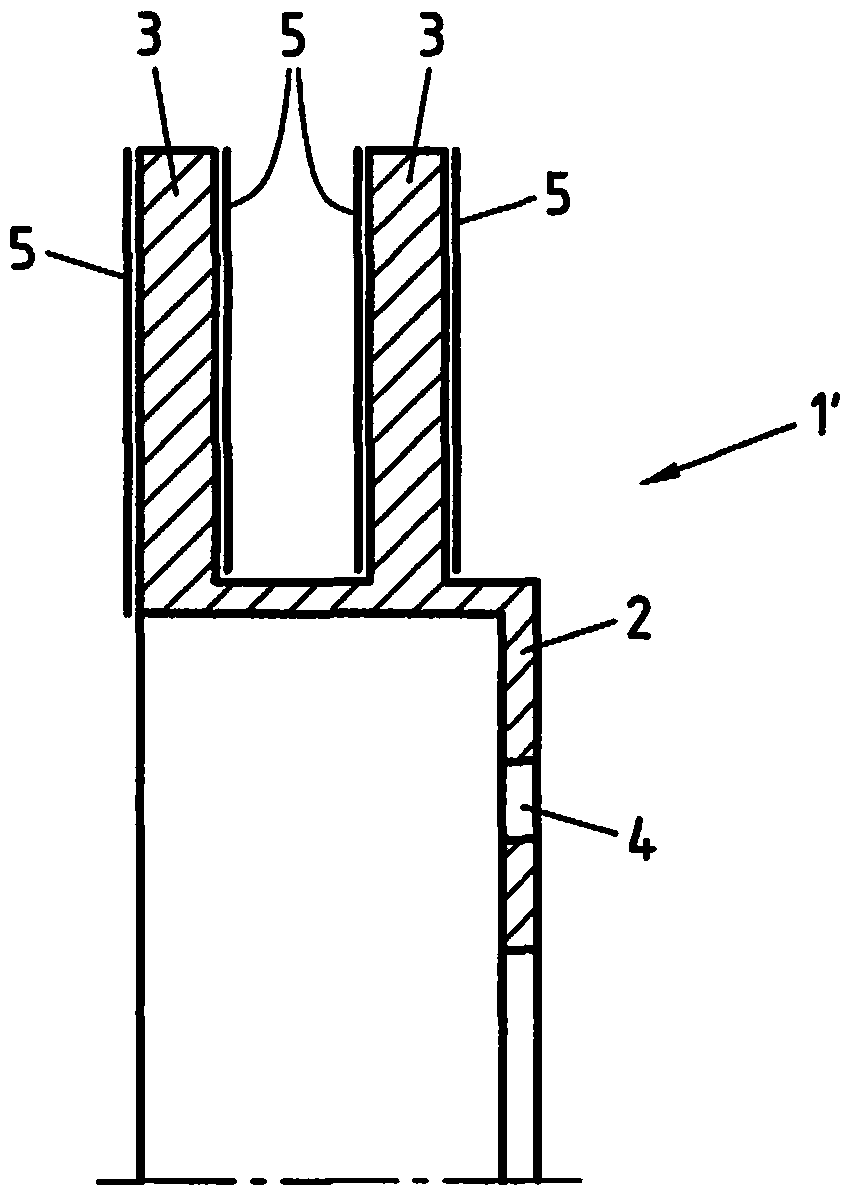

[0024] figure 1 One half of a sectional view of an exemplary embodiment of a brake disc according to the invention is shown. The brake disc 1 includes a brake disc chamber 2 and a friction ring 3 . During braking, the friction ring 3 establishes contact with a brake pad (not shown), so that the rotation of the brake disc 1 is braked by the friction on the friction ring 3 . According to the invention, the brake disc chamber 2 and the friction ring 3 are designed in one piece from a flow-formed material. This has the substantial advantage that firstly the connection between the friction ring and the brake disk chamber has maximum strength. Secondly, thanks to the flow forming process or the flow spinning process, materials other than cast materials can be used for the manufacture of the brake disc, so that sufficiently low wall thicknesses can be achieved. Besides this, another advantage compared to other lightweight solutions is that due to the one-piece design of the brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com