A kind of preparation method of ceramic/resin piezoelectric composite

A technology of composites and ceramics, which is applied in the direction of ceramic products, other household utensils, household utensils, etc., can solve the problems of functionalities that are rarely reported, and achieve the effects of reducing production costs, wide application, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

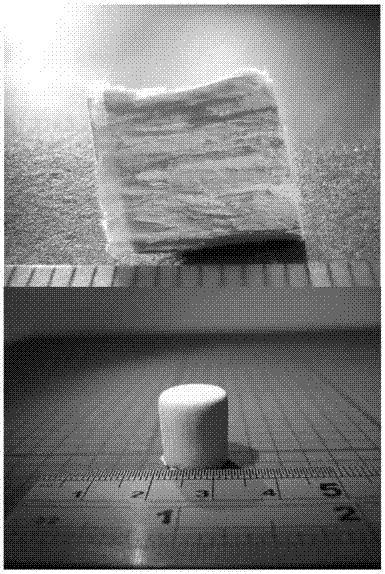

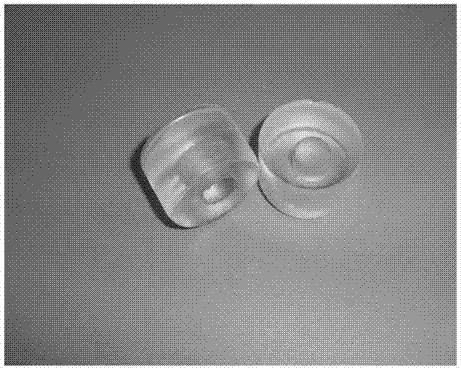

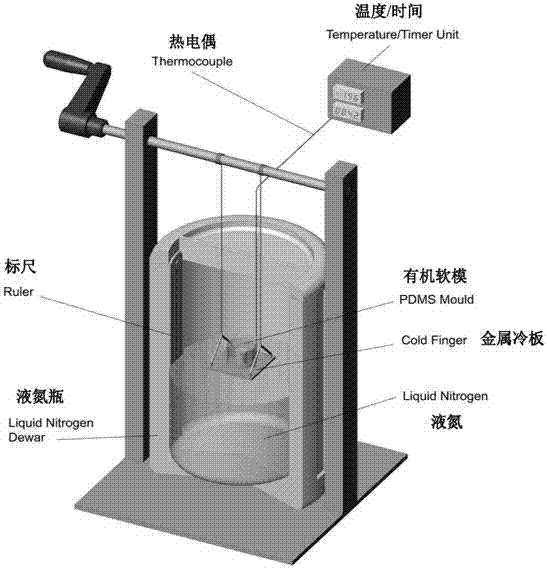

example 1

[0030] In a 60mL polyethylene plastic bottle, weigh 25g of deionized water and add 4 A few drops of PAA 0.03g dispersant, stir evenly; weigh 25g of lead zirconate titanate (PZT), slowly add it into a polyethylene plastic bottle under continuous stirring, and add an appropriate amount of zirconia balls, and ball mill for 24hrs. 3 wt.% (based on dry weight of ceramic powder) of B-1000 and 2 wt.% (based on dry weight of ceramic powder) of B-1007 (acrylic polymer emulsion) were added to the mill jar. Place the mill bottle on the ball mill for slow ball milling for half an hour, inject the suspension into a PDMS (polydimethylsiloxane) organic soft mold with one side opening (such as figure 2 Shown), after vacuum air bubbles (half an hour), the opening was closed with copper foil. Place the organic soft mold upside down on the copper metal cold plate (such as image 3 shown) to start freezing. After the freezing is complete, the sample is removed from the mold and moved to a vac...

example 2

[0032] In a 60mL polyethylene plastic bottle, weigh 20g of deionized water and add 4 A few drops of PAA 0.036g dispersant, stir evenly; weigh 30g of lead zirconate titanate (PZT), slowly add it into a polyethylene plastic bottle under continuous stirring, and add an appropriate amount of zirconia balls, and ball mill for 24hrs. 3 wt.% (based on dry weight of ceramic powder) of B-1000 and 2 wt.% (based on dry weight of ceramic powder) of B-1007 (acrylic polymer emulsion) were added to the mill jar. Place the mill bottle on the ball mill for slow ball milling for half an hour, inject the suspension into a PDMS (polydimethylsiloxane) organic soft mold with one side opening (such as figure 2 Shown), after vacuum air bubbles (half an hour), the opening was closed with copper foil. Place the organic soft mold upside down on the copper metal cold plate (such as image 3 shown) to start freezing. After the freezing is complete, the sample is removed from the mold and moved to a va...

example 3

[0034]In a 60mL polyethylene plastic bottle, weigh 15g of deionized water and add 4 A few drops of PAA 0.042g dispersant, stir evenly; weigh 35g of lead zirconate titanate (PZT), slowly add it into a polyethylene plastic bottle under continuous stirring, and add an appropriate amount of zirconia balls, and ball mill for 24hrs. 3 wt.% (based on dry weight of ceramic powder) of B-1000 and 2 wt.% (based on dry weight of ceramic powder) of B-1007 (acrylic polymer emulsion) were added to the mill jar. Place the mill bottle on the ball mill for slow ball milling for half an hour, inject the suspension into a PDMS (polydimethylsiloxane) organic soft mold with one side opening (such as figure 2 Shown), after vacuum air bubbles (half an hour), the opening was closed with copper foil. Place the organic soft mold upside down on the copper metal cold plate (such as image 3 shown) to start freezing. After the freezing is complete, the sample is removed from the mold and quickly moved ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com