Pelleted fish bait feed and preparation method thereof

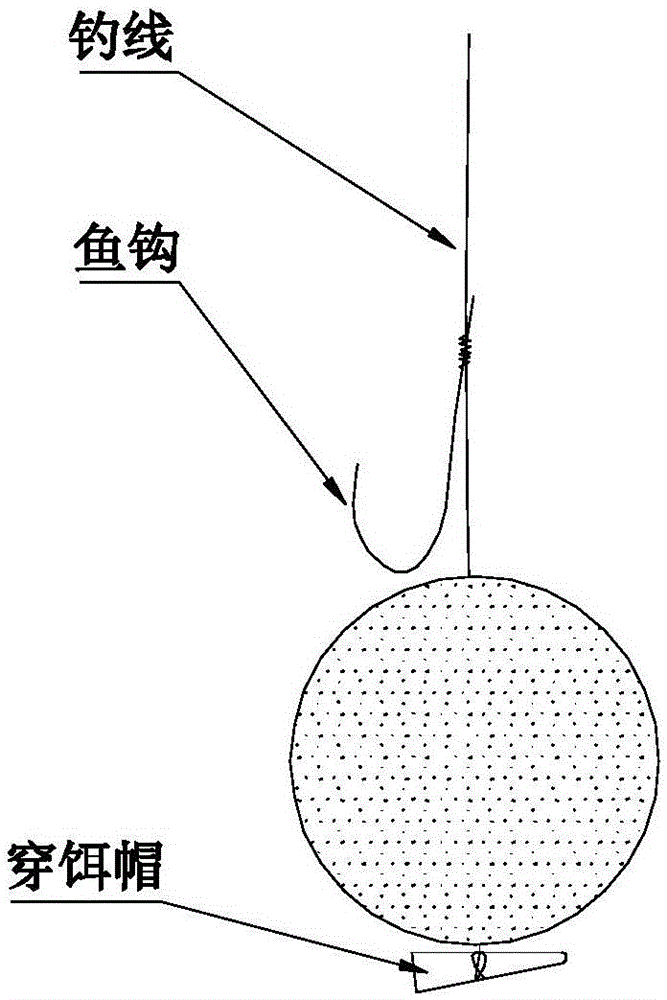

A pellet-shaped fishing bait and feed technology, applied in the field of fish feed, can solve the problems of short sinking time, poor water flow resistance, poor fishing effect, etc., and achieve long sinking time and good food-attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation steps of the bait and feed of the present embodiment are as follows in sequence:

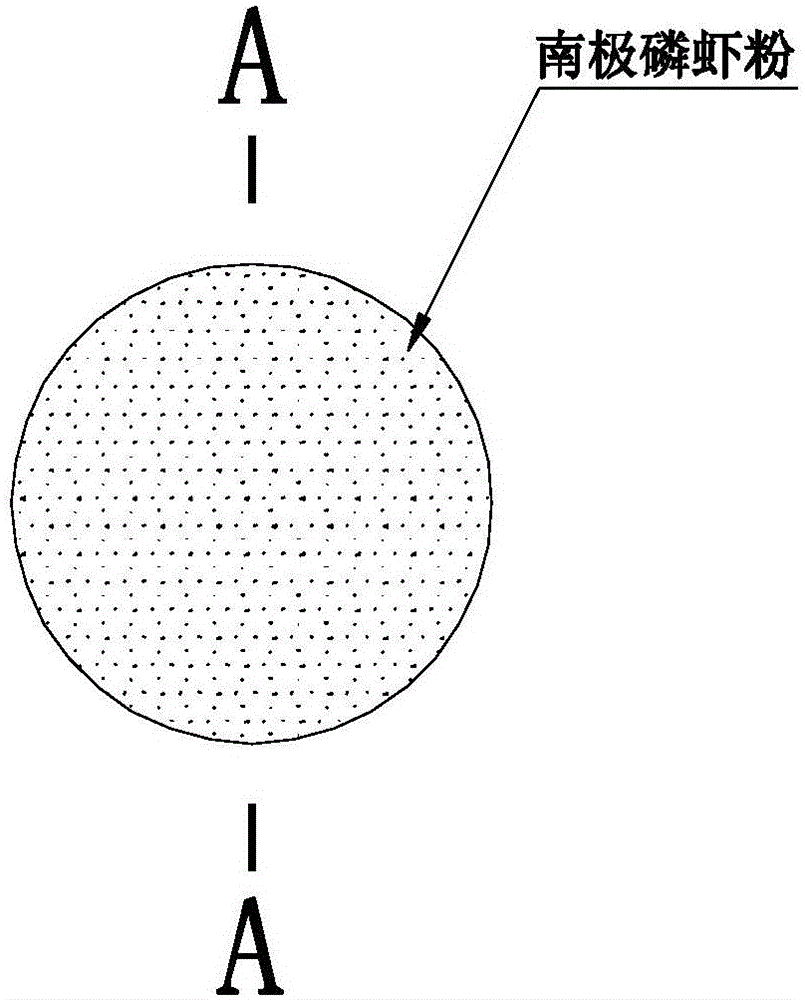

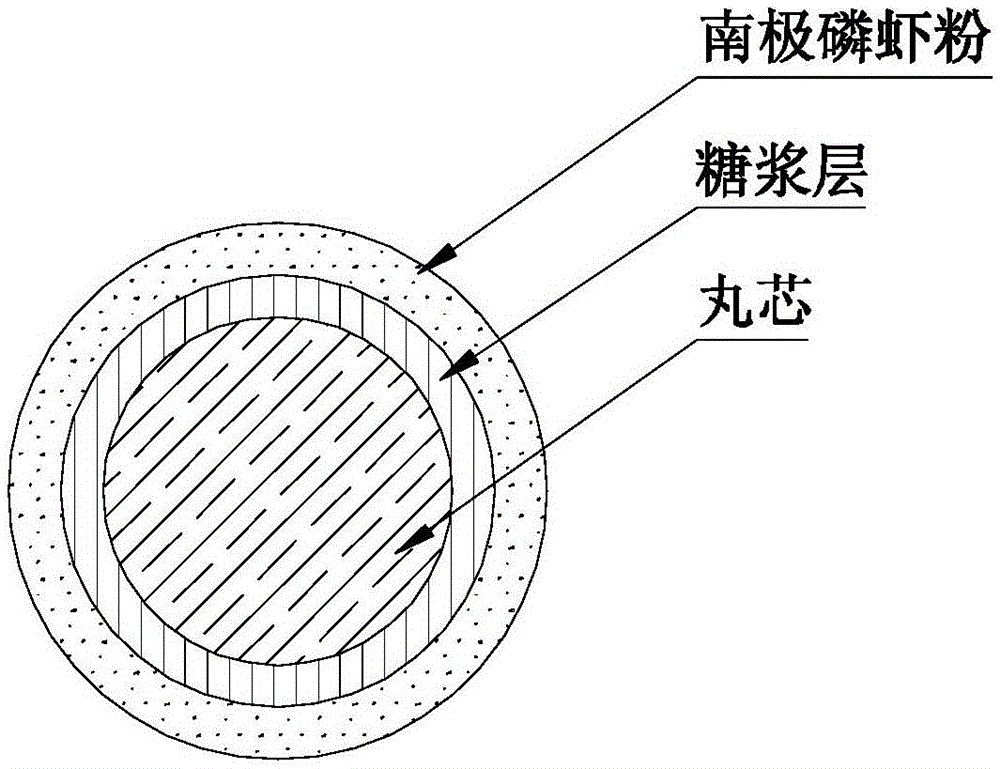

[0046] (1) Weigh the following raw materials according to weight (kg): Antarctic krill powder 25, snail meat powder 18, sweet potato powder 25, potato snowflake powder 12, soybean protein powder 20, and put them all into the mixer, add 20 kg of water , the mixer stirred for 90 minutes;

[0047] (2) Add the mixed raw materials of step (1) in the pellet machine, and press the pellet machine into a ball core with a diameter of 5 mm;

[0048] (3) the pellet core that step (2) is made is passed through the sieve screen of mesh diameter 3 millimeters, and pellet core surface is not closely adhered to the superfluous powder crumb that forms pill shape and removes by the mode of screening;

[0049] (4) Put the ball cores obtained through screening and separation in step (3) into a high-temperature curing box for curing treatment, the curing temperature is 105° C., and the curing ...

Embodiment 2

[0060] The preparation steps of the bait and feed of the present embodiment are as follows in sequence:

[0061] (1) Weigh the following raw materials according to weight (kg): Antarctic krill powder 30, snail meat powder 12, sweet potato powder 23, potato snowflake powder 10, soybean protein powder 25, and put them all into the mixer, add 30 kg of water , the mixer stirred for 100 minutes;

[0062] (2) Add the mixed raw materials of step (1) in the pellet machine, and press the pellet machine into a ball core with a diameter of 13 mm;

[0063] (3) the pellet core that step (2) is made is passed through the sieve screen of mesh diameter 3.5 millimeters, and pellet core surface is not closely adhered to the superfluous powder crumb of pill shape and is removed by the mode of screening;

[0064] (4) Put the ball core obtained by screening and separating in step (3) into a high-temperature curing box for curing treatment, the curing temperature is 115° C., and the curing time is...

Embodiment 3

[0075] The preparation steps of the bait and feed of the present embodiment are as follows in sequence:

[0076] (1) Weigh the following raw materials according to weight (kg): Antarctic krill powder 37, snail meat powder 8, sweet potato powder 18, potato snowflake powder 20, soybean protein powder 17, and put them all into the mixer, add 40 kg of water , the mixer stirred for 110 minutes;

[0077] (2) Add the mixed raw materials of step (1) in the pellet machine, and press the pellet machine into a ball core with a diameter of 21 mm;

[0078] (3) the pellet core that step (2) is made passes through the sieve screen of mesh diameter 4.5 millimeters, and pellet core surface is not closely adhered to the superfluous powder crumb of pellet shape and removes by the mode of screening;

[0079] (4) Put the ball cores obtained through screening and separation in step (3) into a high-temperature curing box for curing treatment, the curing temperature is 125° C., and the curing time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com