Device and method for manufacturing metal flashing plastic through ultrasonic treatment

A metal flash and ultrasonic technology, which is applied in the field of devices for preparing metal flash effect plastics by ultrasonic treatment, can solve the problems of uneven dispersion of inorganic rigid pigments, weakening of the interface bonding force of plastic substrates, and reduction of mechanical properties of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

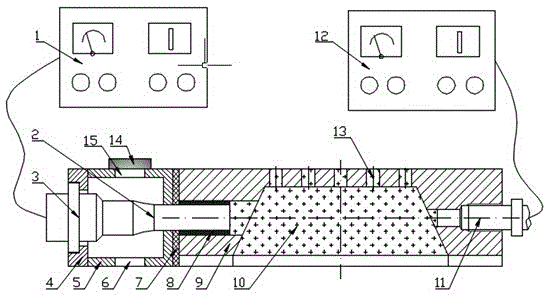

[0022] The structure diagram of the present invention is as figure 1 As shown, the ultrasonic treatment of the present invention prepares the device of metal glitter effect plastics, comprises extruding die 9, is provided with extruding mold cavity and is provided with discharge port 13 in extruding die 9, discharge port 13 and extruding model The cavities are connected, and the blended plastic 10 in the cavity of the extrusion model can be extruded through the discharge port 13, wherein one side of the extrusion die 9 is provided with a support frame 5, and the other side of the extrusion die 9 is provided with a temperature sensor 11, An ultrasonic vibration control device is installed on the support frame 5, and the ultrasonic vibration control device includes an ultrasonic generator 1, a horn 2, and a transducer 3, wherein one end of the transducer 3 is connected with the ultrasonic generator 1, and the transducer 3 The other end of the horn 2 is connected to one end of th...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is: the formula of 3 kinds of blended plastics 10 is as follows:

[0047] 11) AES resin 100phr, particle size 100μm high flash aluminum powder 5phr, coupling agent 3phr;

[0048] 12) 100phr of PU resin, 5phr of high-gloss aluminum powder with a particle size of 100μm, and 3phr of coupling agent;

[0049] 13) PC resin 100phr, particle size 100μm high flash aluminum powder 5phr, coupling agent 3phr.

Embodiment 3

[0051] The difference between this embodiment and embodiment 1 is: the formula of 3 kinds of blended plastics 10 is as follows:

[0052] 11) AES resin 100phr, particle size 50μm high flash aluminum powder 3phr, coupling agent 1.5phr;

[0053] 12) 100phr of PU resin, 3phr of high-gloss aluminum powder with a particle size of 50μm, and 1.5phr of coupling agent;

[0054] 13) PC resin 100phr, particle size 50μm high flash aluminum powder 3phr, coupling agent 1.5phr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com