Drainpipe net sludge integrated treatment method

A drainage pipe network and treatment method technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve problems such as low efficiency, affecting people's lives, production, road surface water, etc., and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the drawings and specific embodiments.

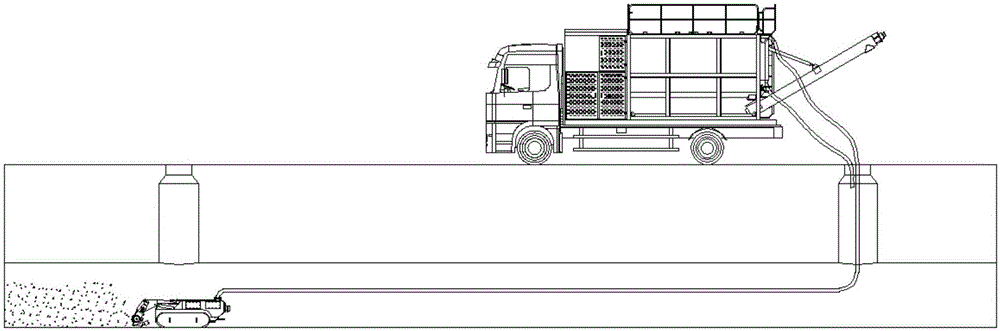

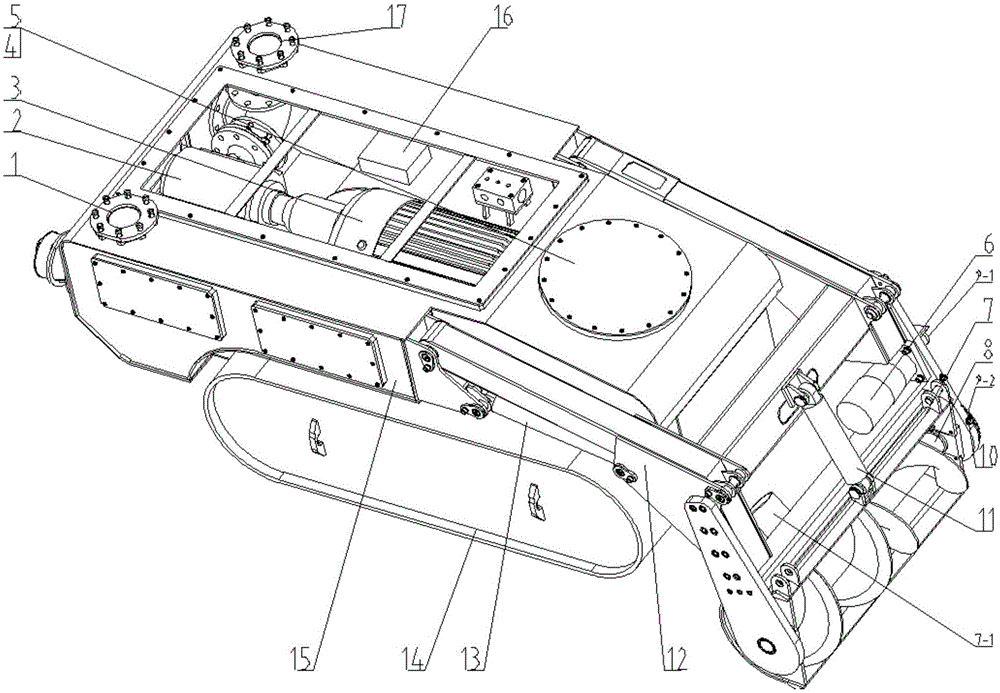

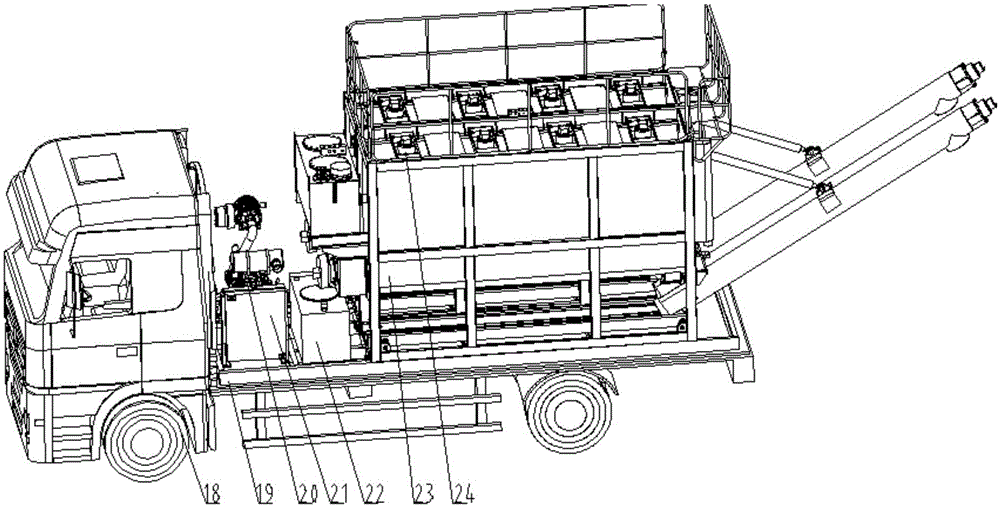

[0046] Such as Figure 1-4 As shown, the sludge treatment system of the drainage pipe network of the present invention includes a crawler dredging robot and a mud-water separation robot, such as figure 1 As shown, the crawler dredging robot for the drainage pipe network includes dredging execution components, silt conveying components, cavity 15, traveling components, ground control boxes, control cables, electric control boxes 16, and signal feedback components.

[0047] The dredging execution components include a stirring actuator, a stirring adjustment mechanism, and a stirring power end;

[0048] The mixing actuator includes a mixing motor 6, a bucket 7, a mixing shaft 8, and a bucket cylinder 11. The output end of the mixing motor 6 is equipped with a sprocket 9-1, and the right end of the mixing shaft is equipped with a sprocket 9-2. The mixing motor 6 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com