A tgb cement polystyrene line building material

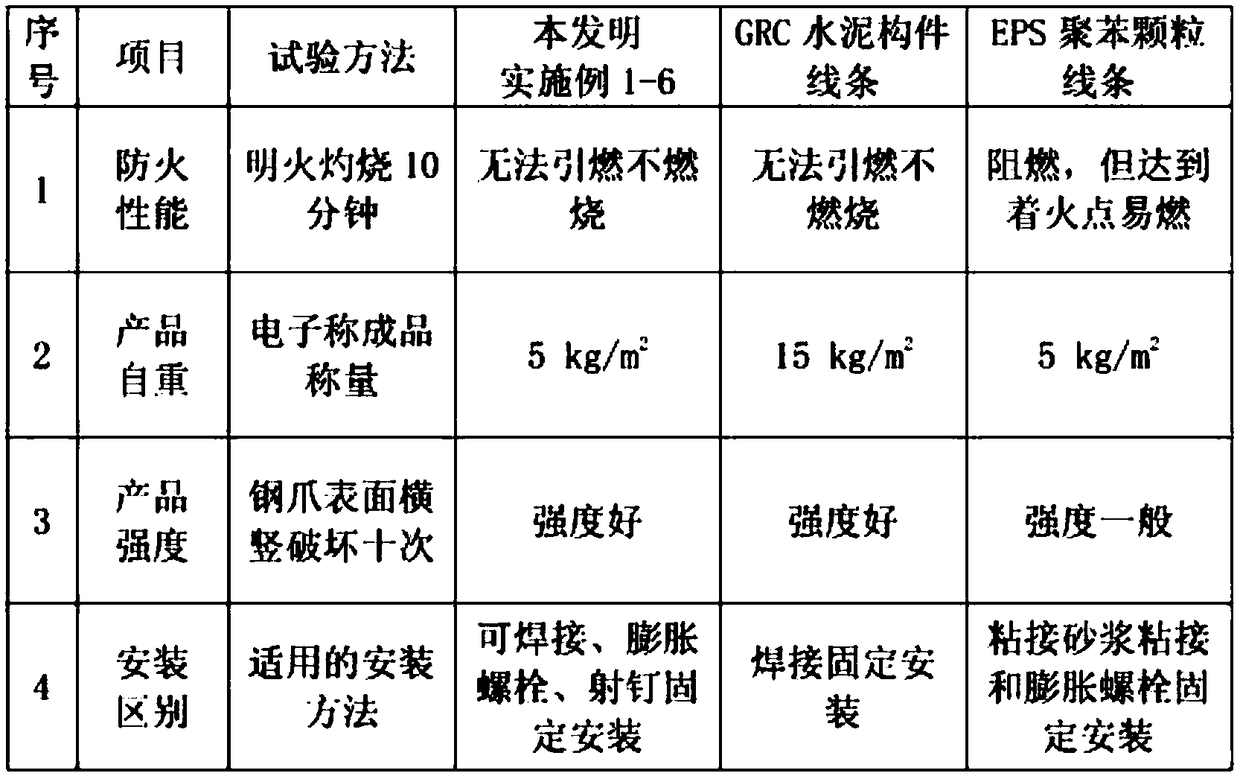

A polystyrene line and cement technology, which is applied in the direction of architecture and building structure, can solve the problems of GRC cement line self-heavy stretching requirements, cumbersome and cumbersome installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] No. 425 high-strength low-alkali cement 10%, polystyrene foam particles 70%, fine sand 2%, emery 4%, hydrogel 8%, ¢6 welded steel bars 2%, ﹪4 skeleton tendons 3%, glass fiber filaments 0.5 ﹪, special rubber powder 0.5﹪

Embodiment 2

[0049] No. 425 high-strength low-alkali cement 15%, polystyrene foam particles 60%, fine sand 5%, emery 4%, hydrogel 2%, ¢6 welded steel bars 5%, ﹪4 skeleton tendons 5%, glass fiber 1 ﹪、Special rubber powder 3﹪

Embodiment 3

[0051] No. 425 high-strength low-alkali cement 20%, polystyrene foam particles 60%, fine sand 3%, emery 3%, hydrogel 6%, ¢6 welded steel bars 2%, ﹪4 skeleton tendons 3%, glass fiber 1 ﹪, special rubber powder 2﹪

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com