Preparation method of egg yolk oil

A technology of egg butter and egg yolk powder, which is applied in the direction of fat oil/fat production, fat generation, medical raw materials derived from birds, etc., can solve the problems of high cost and low yield, and achieve low cost, taking into account both cost and yield, The effect of low extraction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0023] Experimental example 1 The preparation method of egg oil

[0024] Pretreatment: After breaking the eggs, use an egg white separator to separate the egg yolks, ripen them at 100-105°C, grind them, continue drying at 70-80°C until the water content is ≤5%, grind them, and pass through a No. 1 sieve to obtain egg yolk powder.

[0025] Take egg yolk powder 1000g, measure its water content ≤ 5%, extract egg yolk by supercritical carbon dioxide extraction method, extraction temperature is 50 ℃, extraction pressure 35Mpa, CO 2 The flow rate is 50L / h, and the extraction time is 120min.

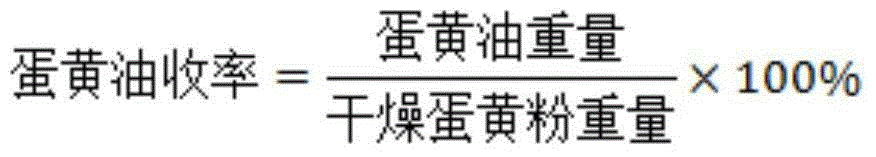

[0026] Repeat three times, collect egg oil and yield as following table:

[0027] Test No.

[0028] It can be seen that there is little difference in the yield of the method of the present invention, indicating that the method of the present invention is stable. In addition, the average yield of the method of the present invention is 42.65%.

experiment example 2

[0029] Experimental example 2 The preparation method of egg oil

[0030] Pretreatment: After breaking the eggs, use an egg white separator to separate the egg yolks, ripen them at 100-105°C, grind them, continue drying at 70-80°C until the water content is ≤5%, grind them, and pass through a No. 1 sieve to obtain egg yolk powder.

[0031] Take egg yolk powder 1000g, measure its water content ≤ 5%, extract egg yolk by supercritical carbon dioxide extraction method, extraction temperature is 50 ℃, extraction pressure 38Mpa, CO 2 The flow rate is 50L / h, and the extraction time is 105min.

[0032] A total of 355 g of egg oil was collected, and the yield of egg oil was 35.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com