A kind of non-hard phase matrix formula for impregnated diamond drill bit and preparation method thereof

A technology of impregnated diamond and hard phase is applied in the preparation of matrix, matrix formulation without hard phase and its preparation field, which can solve the problems of excessive wear of drill bits, easy segregation of density differences, short working life, etc. The sintering process is simple, the material performance is good, and the comprehensive performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

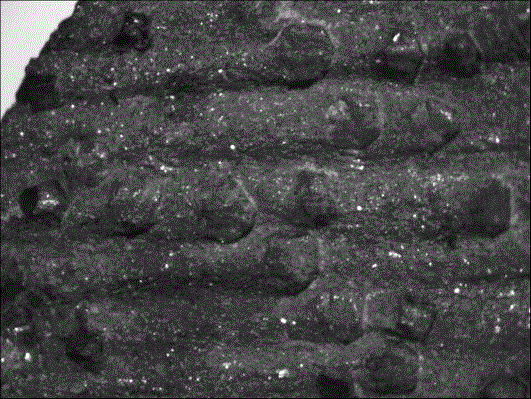

specific example 1

[0018] The diamond composite material without hard phase matrix prepared by pressureless impregnation sintering, its composition and mass ratio are: pure Fe powder (300 mesh) 30%, pure Ni powder (200 mesh) 11%, pure Co powder 2.5% , Cu alloy 55%, P powder, B powder and Si powder (200 orders) account for 0.5% respectively, select the volume concentration of diamond particle size 35 / 40 order and 25% for use, the brazing flux quality is 30% of Cu alloy quality, use Mix the above materials evenly with alcohol, put them into a graphite mold, cover the upper layer with Cu alloy and brazing flux, dry them and place them in an intermediate frequency furnace for pressureless sintering. The sintering temperature is 1000°C, and the holding time is 5 minutes. 5mm diamond composite matrix test block. Grinding the test block with the SiC grinding wheel, the surface morphology of the diamond particles on the friction surface of the test block is good, and the interface between the diamond an...

specific example 2

[0020] The impregnated diamond drill bit without hard phase prepared by pressureless impregnation sintering, its composition and proportion are: pure Fe (300 mesh) 28%, pure Ni (200 mesh) 11%, pure Co powder 2%, Cu alloy 56 %, the quality of brazing flux is 35% of Cu alloy quality, P powder, B powder and Si powder (200 mesh) account for 1% respectively, select diamond particle size 35 / 40 mesh and 35% volume concentration, mix the above materials with alcohol Evenly, put it into a graphite mold, cover the upper layer with Cu alloy and brazing flux, dry it and place it in an intermediate frequency furnace for pressureless sintering, the sintering temperature is 1000 ° C, keep it for 10 minutes, and sinter into a diamond-impregnated drill bit without hard phase. The non-hard phase impregnated diamond drill bit prepared by the pressureless method has good formability, fast drilling speed and long working life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com