Porefilling electroplating leveling agent, preparation method and electroplating liquid using leveling agent

A technology of leveling agent and electroplating solution, which is applied in the field of electroplating solution, hole filling electroplating leveler and its preparation, to achieve excellent hole filling performance and improve the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

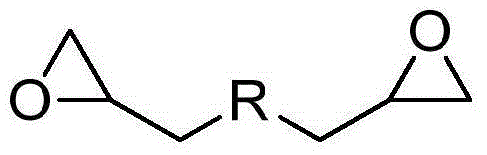

[0046] Take a 1L double-necked round-bottom flask, equipped with a cold flow reflux tube and a dropping funnel, and add 300mL of deionized water into the flask. At room temperature, 0.5mol of 3-(dimethylamino)-1-propanethiol and 0.5mol of piperazine were successively dissolved in the reaction system, and stirred at room temperature for 10 minutes; (3.3) Add dropwise to the reaction system in the flask from the dropping funnel, and then raise the temperature of the reaction system to 60°C for polymerization; react for 24 hours and cool to room temperature to obtain a yellow viscous solution, which is the hole-filling electroplating leveler.

Embodiment 2

[0048]Take a 1L double-neck round bottom flask, equipped with a cold flow reflux tube and a dropping funnel, and add 300mL of deionized water into the flask. At room temperature, 0.5mol of 3-(dimethylamino)-1-propanethiol and 0.5mol of piperazine were successively dissolved in the reaction system, and stirred at room temperature for 10 minutes; (3.6) Add dropwise to the reaction system in the flask from the dropping funnel, and then raise the temperature of the reaction system to 80°C for polymerization; after 24 hours of reaction, cool to room temperature to obtain a yellow viscous solution, which is the hole-filling electroplating leveler.

Embodiment 3

[0050] Take a 1L double-neck round bottom flask, equipped with a cold flow reflux tube and a dropping funnel, and add 300mL of deionized water into the flask. At room temperature, 0.3mol of 3-(dimethylamino)-1-propanethiol and 0.4mol of piperazine were successively dissolved in the reaction system, and stirred at room temperature for 15 minutes; Compound (3.1) was added dropwise into the reaction system in the flask from the dropping funnel, and then the reaction system was heated to 70°C for polymerization; after 24 hours of reaction, it was cooled to room temperature to obtain a yellow viscous solution, which was the hole-filling electroplating leveler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com