High-quality fabric dyeing machine

A high-quality, dyeing machine technology, applied in the field of dyeing machines, can solve the problems of unguaranteed fabric quality and shorten the service life of fabrics, and achieve the effect of prolonging service life, improving quality and avoiding friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

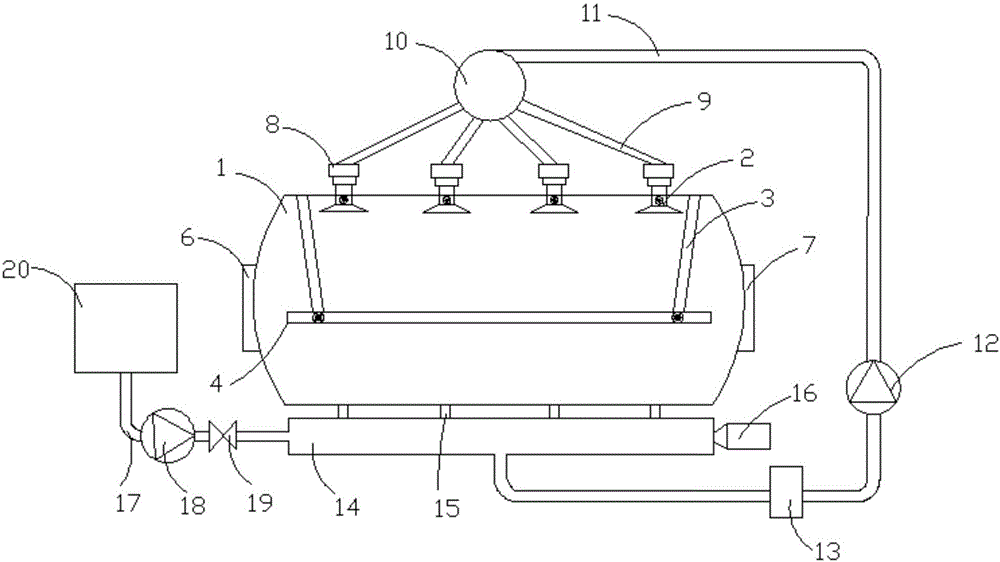

[0017] Example: such as Figure 1-2 As shown, the present invention provides a high-quality cloth dyeing machine, including a dyeing body 1, a dye vat 20, a circulation pipe 11, a dye output pipe 17, a cloth inlet 6 and a cloth outlet 6, and a dyeing liquid spraying probe is arranged inside the dyeing body 1 2. The swing arm 3 and the swing frame 4, the swing frame 4 is provided with a cloth hanging rod 5, one side of the dyeing body 1 is provided with a cloth inlet 6 and the other side of the dyeing body 1 is provided with a cloth outlet 7, and the top of the dyeing body 1 is provided with a spray The probe connecting piece 8, the spraying probe connecting piece 8 is connected to the dispensing pipe 9, the other end of the dispensing pipe 9 is connected to the dispensing device 10, one side of the dispensing device 10 is connected to the circulation pipeline 11, and the circulation pipeline 11 is provided with a main pump 12 and a filter The other end of the device 13 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com