Electric power maintenance ladder

A technology for power maintenance and ladder posts, applied in ladders, overhead lines/cable equipment, buildings, etc., can solve the problems of unstable high-voltage lines, unfavorable environmental protection, damage to the green environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

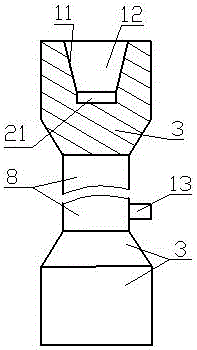

[0077] The power maintenance ladder of the present invention mainly includes a fixed seat 16, a connecting seat 17, a locking screw 18, a connecting shaft 15, a bearing seat 1, a gravity cone 19, a ladder column 2, a connecting column, a self-locking device, an outer cone surface 10, an inner cone Hole 12, inner tapered surface 11;

[0078] The power maintenance ladder adopts a single-column support type, and the fixed seat 16 and the connecting seat 17, the bearing seat 1, the ladder column 2 and the connecting column are combined into a single-column series type, and the carrying ladder column 2 and the connecting column and the ladder column 2 and the connection The carrier of the weight borne by the column is the fixed base 16; when the ladder column 2 is installed, the rotating joint capable of adjusting the installation angle of the fixed base 16 and the bearing base 1 is the connecting base 17 and the bearing base 1 connected by the connecting shaft 15.

[0079] The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com