Cooling tower water return power generation device and power generation method by using same

A technology for power generation devices and cooling towers, applied in the directions of hydropower generation, safety devices, engine components, etc., can solve problems such as ineffective utilization and waste of water potential energy, and achieve the effects of improving self-generation rate, significant economic benefits, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

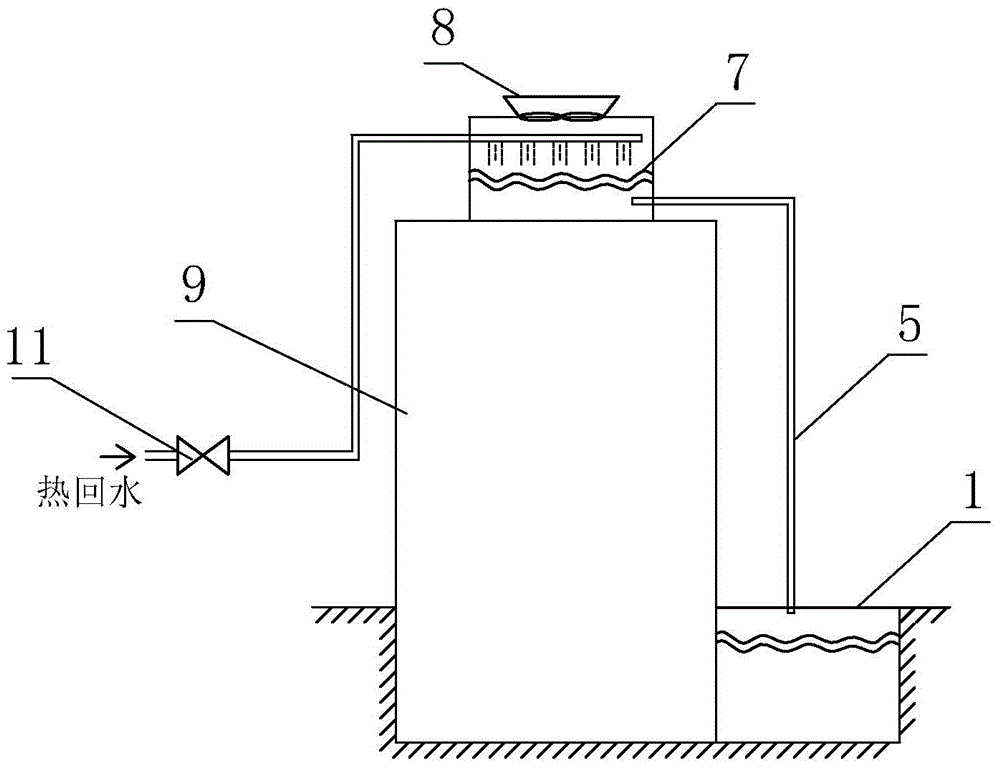

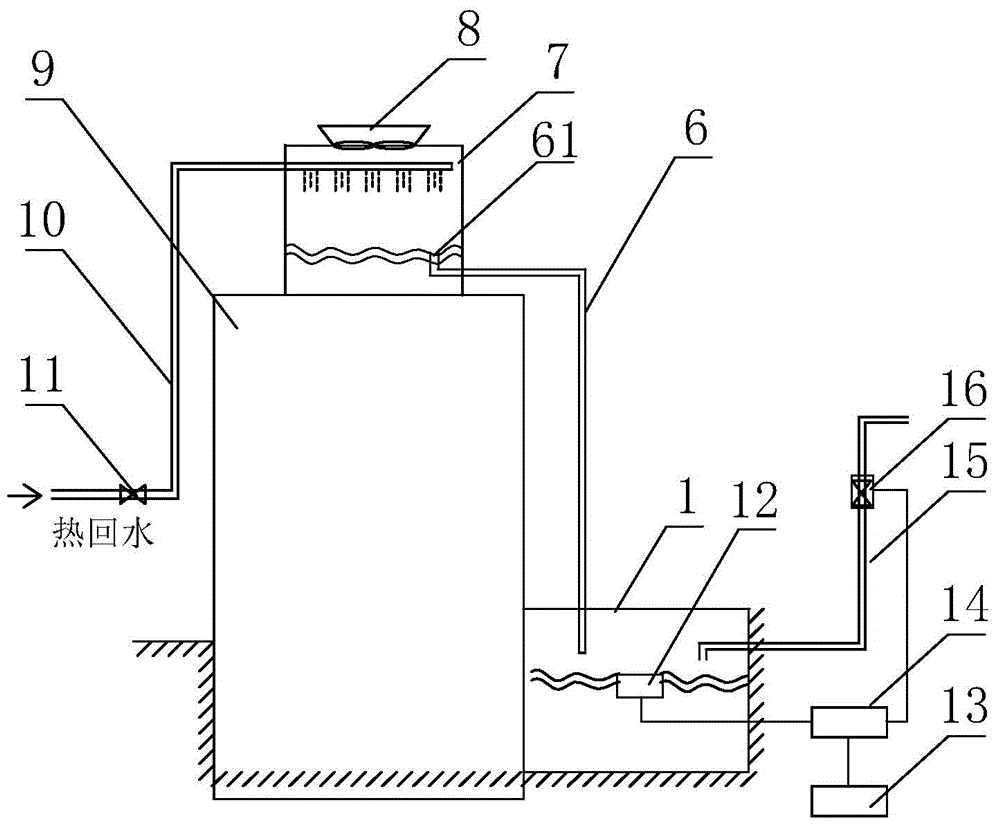

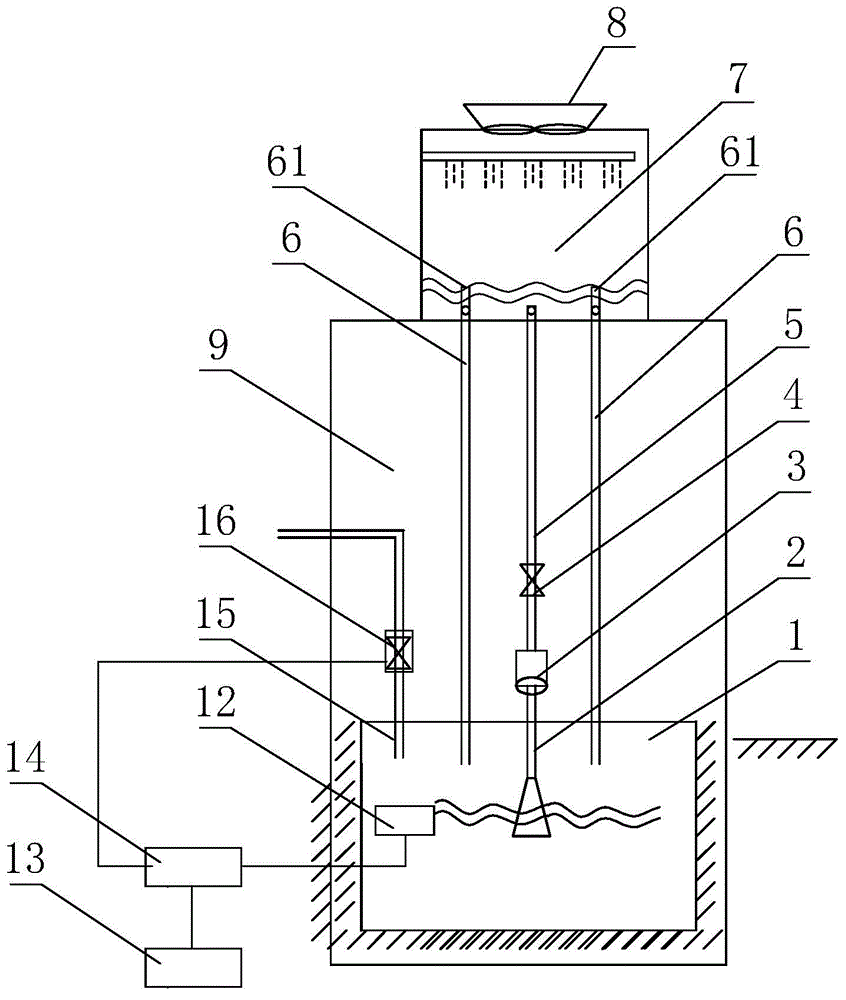

[0034] A cooling tower backwater power generation device, including a cooling tower 8 installed on the top of a water pump house 9, a collecting pool 7 and a backwater pool 1 located on the ground. The backwater hot water of process equipment is transported to the cooling tower through a hot water pipe 10, and the collection The pool 7 is connected to the return pool 1 through the return pipe 5; the cooling tower return water power generation device also includes a power generation component and a liquid level control device. The power generation component is installed at the end of the return pipe 5 close to the return pool 1, including the inlet water Valve 4, generator set 3 and water outlet pipe 2. The inlet end of the inlet valve 4 is connected with the outlet of the return pipe 5, the outlet end of the inlet valve is connected with the inlet of the generator set 3, and the outlet of the generator set is connected The outlet pipe 2, which is connected to the return pool 1 a...

Embodiment 2

[0040] A method for generating electricity using the above-mentioned cooling tower backwater power generation device includes the following steps:

[0041] A. Install power generation components and liquid level control devices

[0042] Connect the power generation components to the cooling tower return pipe 5 in turn: the water inlet of the turbine of the generator set is connected to the outlet of the return pipe 5 through the inlet valve 4, and the water outlet of the turbine is connected to the return pool 1 through the outlet pipe 2, closing the water inlet Valve 4;

[0043] Connect the overflow pipe 6 and the return pipe in parallel to the water collection tank 7. The lower end of the overflow pipe is connected to the return water tank 1. The upper end of the overflow pipe extends into the water collection tank, the overflow port 61 of the overflow pipe faces upward, and the overflow port is away from the collection tank. The height of the bottom of the pool is higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com