Superhigh-temperature subcritical gas power generation system

A power generation system, subcritical technology, applied in the direction of steam generation, liquid degassing, machine/engine, etc., can solve the problems of low calorific value of gas, restricting the development of enterprises, and a large proportion of gas, so as to achieve a good combustion atmosphere and solve resources Waste, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

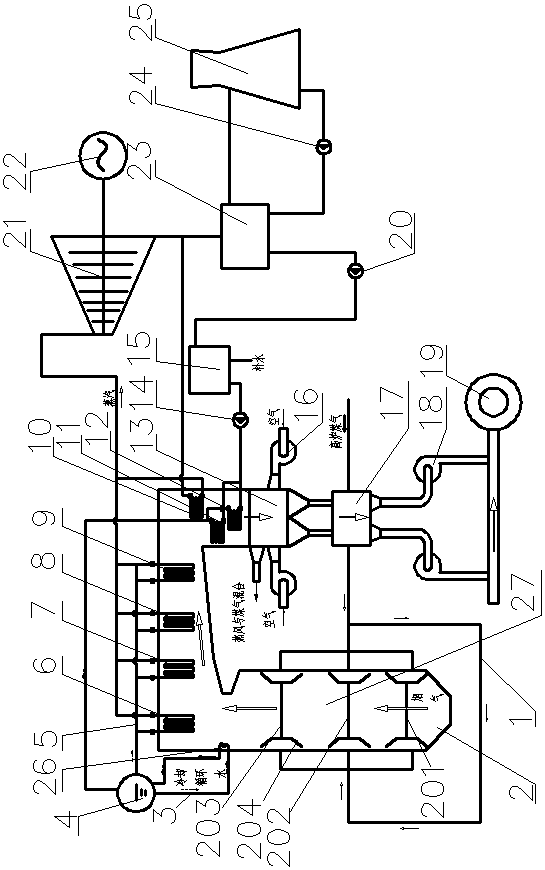

[0066] The present invention is described in detail below with reference to accompanying drawing and embodiment:

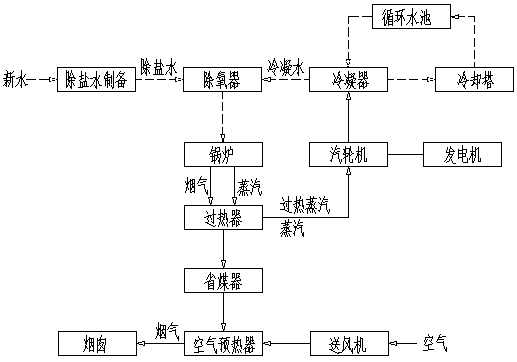

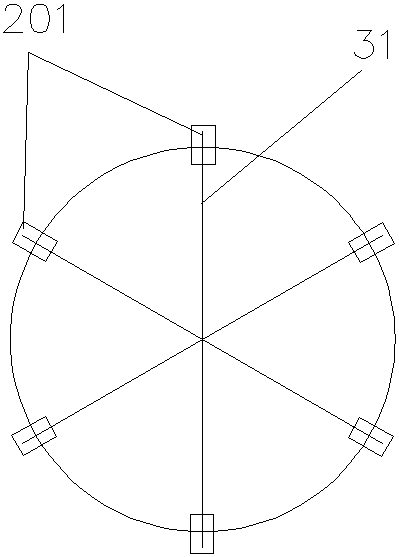

[0067] attached Figure 1-5 It can be seen that an ultra-high temperature subcritical gas power generation system,

[0068] Including a gas boiler 2, an intermediate reheating condensing steam turbine 21 and a generator set 22;

[0069] Generating set 22 comprises the steam turbine 21 that is connected with gas boiler pipeline;

[0070] The gas boiler 2 includes a furnace 27 and a water wall 26 in the boiler;

[0071] The flue gas-coal gas heat exchanger 17 is connected to the gas boiler 2 through the blast furnace gas pipeline 1;

[0072] A steam drum 4 is arranged outside the gas boiler 2, and the steam drum 4 is connected to the water inlet of the panel superheater 6, the high temperature superheater 7, the high temperature reheater 8 and the steam convection tube panel 9 in turn through the steam pipeline 5;

[0073] The panel superheater 6, the high tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com