Two-cylinder positive displacement compressor and control method

A variable-capacity compressor and control method technology, applied in the field of compressors, can solve problems such as high power consumption, low energy efficiency, and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

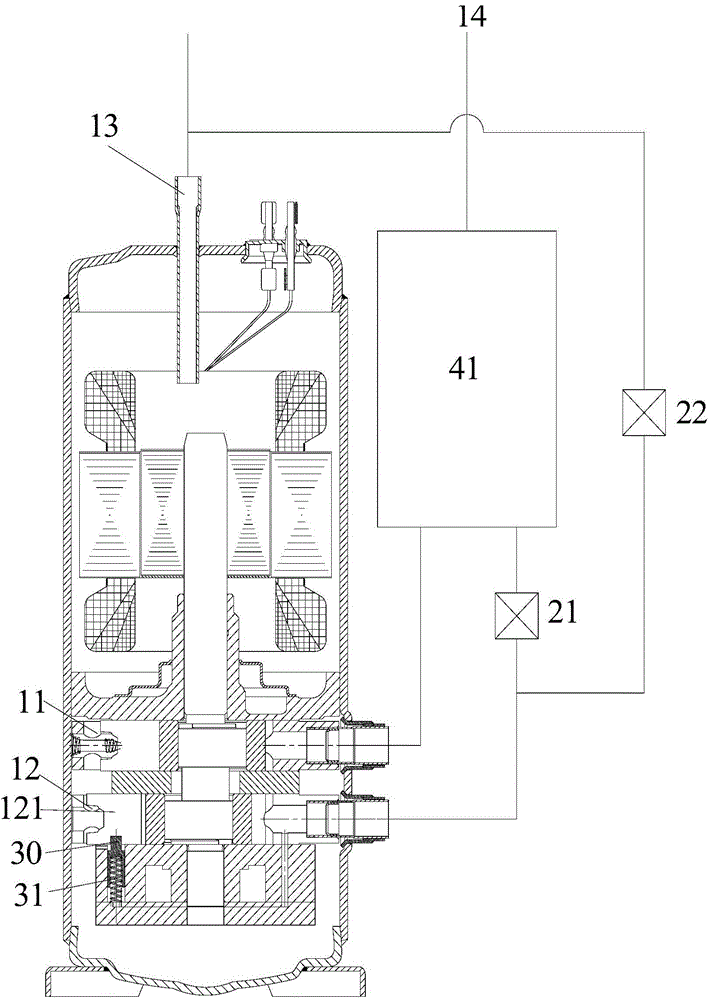

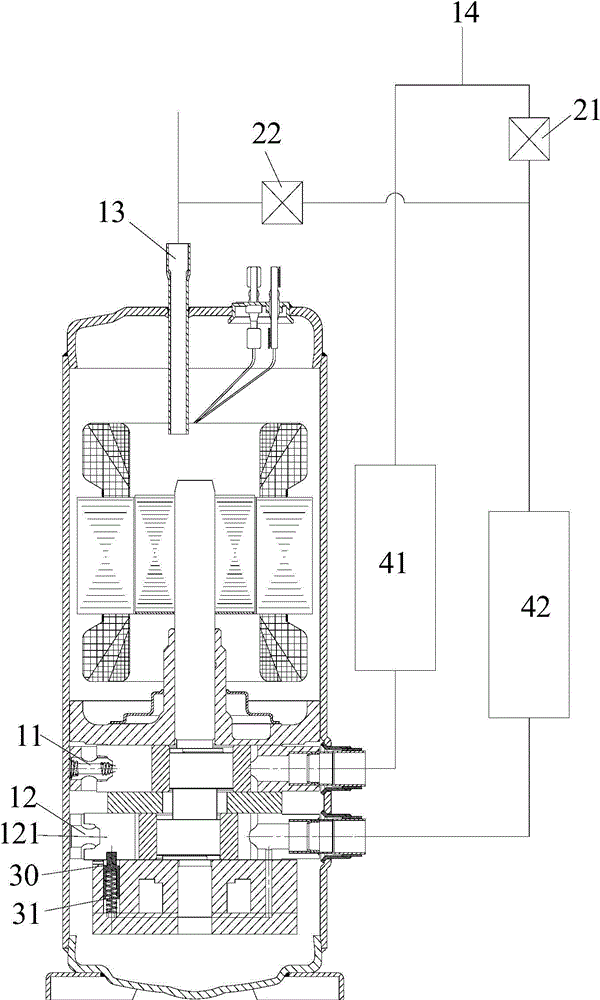

[0022] See figure 1 with figure 2 , The two-cylinder variable displacement compressor according to the present invention includes: a first cylinder 11 and a second cylinder 12; a compressor exhaust port 13, which communicates with the intake port of the second cylinder 12; and an intake port 14, respectively The intake port of the first cylinder 11 communicates with the intake port of the second cylinder 12; the first solenoid valve 21 is arranged between the intake port 14 and the intake port of the second cylinder 12; the second solenoid valve 22, It is arranged between the compressor discharge port 13 and the air inlet of the second cylinder 12; the sliding plate 121 is arranged in the second cylinder 12; the pin 30 is arranged in the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com