Automatic material preparation device with screening function

A screening device and automatic batching technology, applied in the field of smelting and casting, can solve the problems of slow batching speed, large raw material particles, incomplete reaction, etc., and achieve high batching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

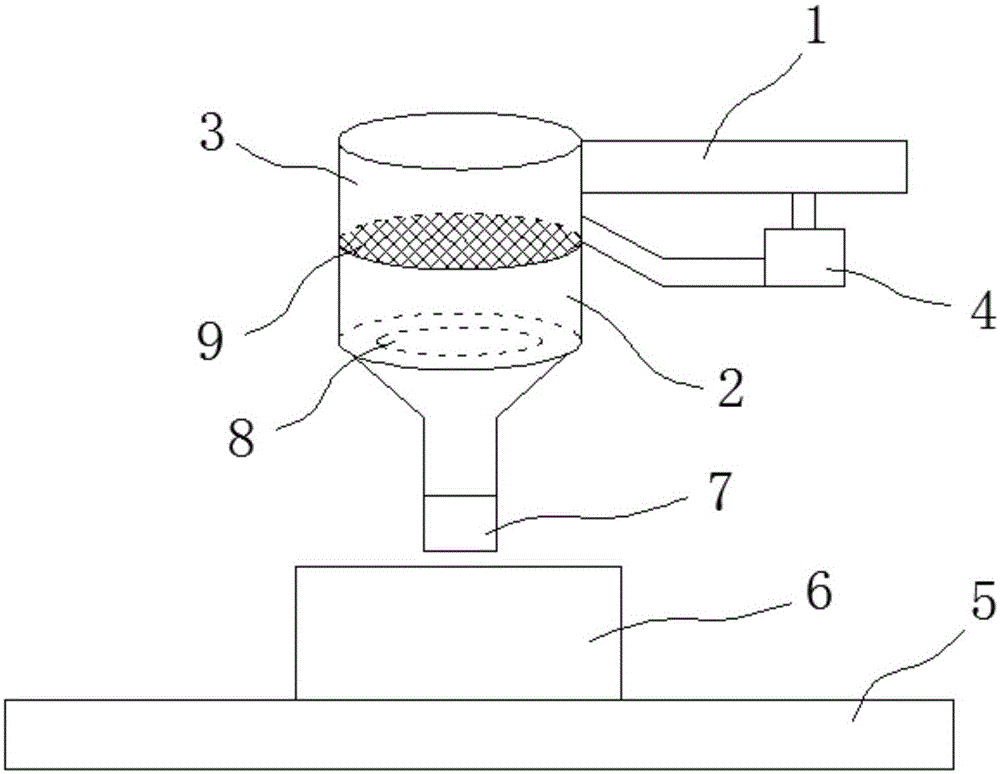

[0016] Such as figure 1 As shown, a kind of automatic batching device capable of screening comprises feed pipe 1, batching bin 2, screening device 3, pulverizer 4 and conveyer belt 5, and described screening device 3 is fixedly placed on the upper end of described batching bin 2, so The feed pipe 1 is communicated with the upper end of the screening device 3, and the bottom of the screening device 3 is provided with a screening net 9, and one side of the screening device 3 is communicated with the input end of the pulverizer 4 through a pipeline, so that The output end of the pulverizer 4 communicates with the feed pipe 1 through a pipeline, and the lower end of the batching bin 2 is provided with an electric unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com