Spray gun for prolonging service life of mold coating in metal mold casting

A metal mold casting and mold coating technology, which is applied in the manufacture of tools, casting molding equipment, metal processing equipment, etc., can solve the problems of uneven coating composition, coating performance and service life, etc., to improve coating life, uniform coating composition, Realize the effect of real-time networking and intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

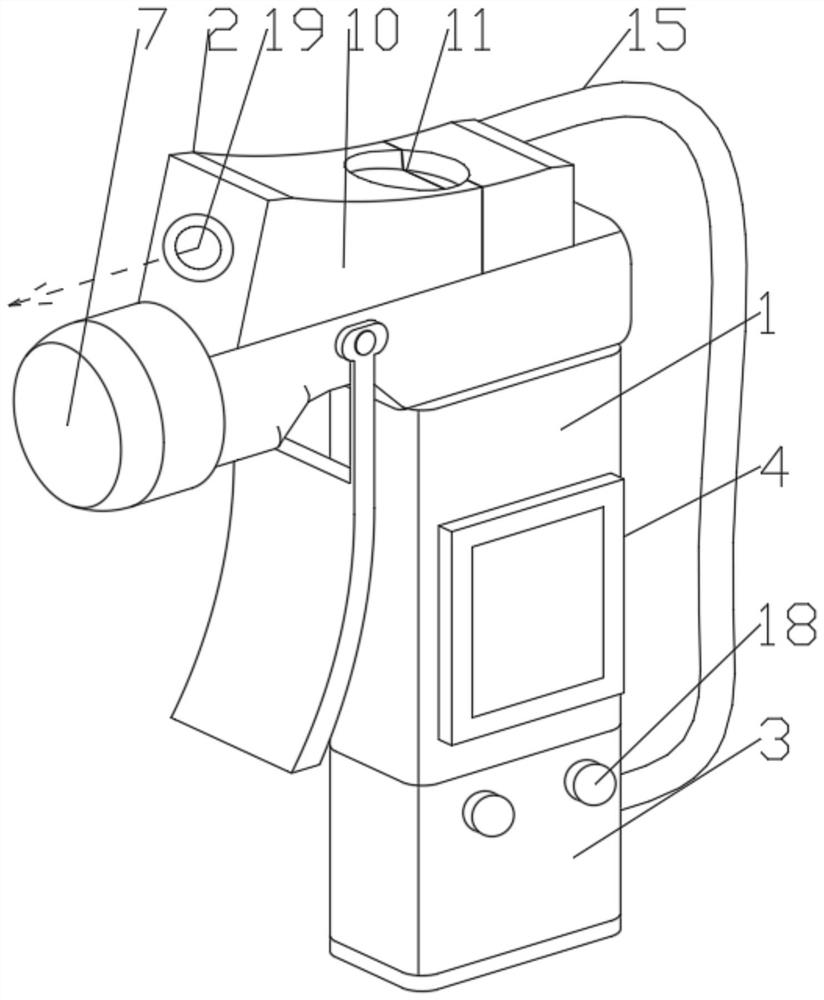

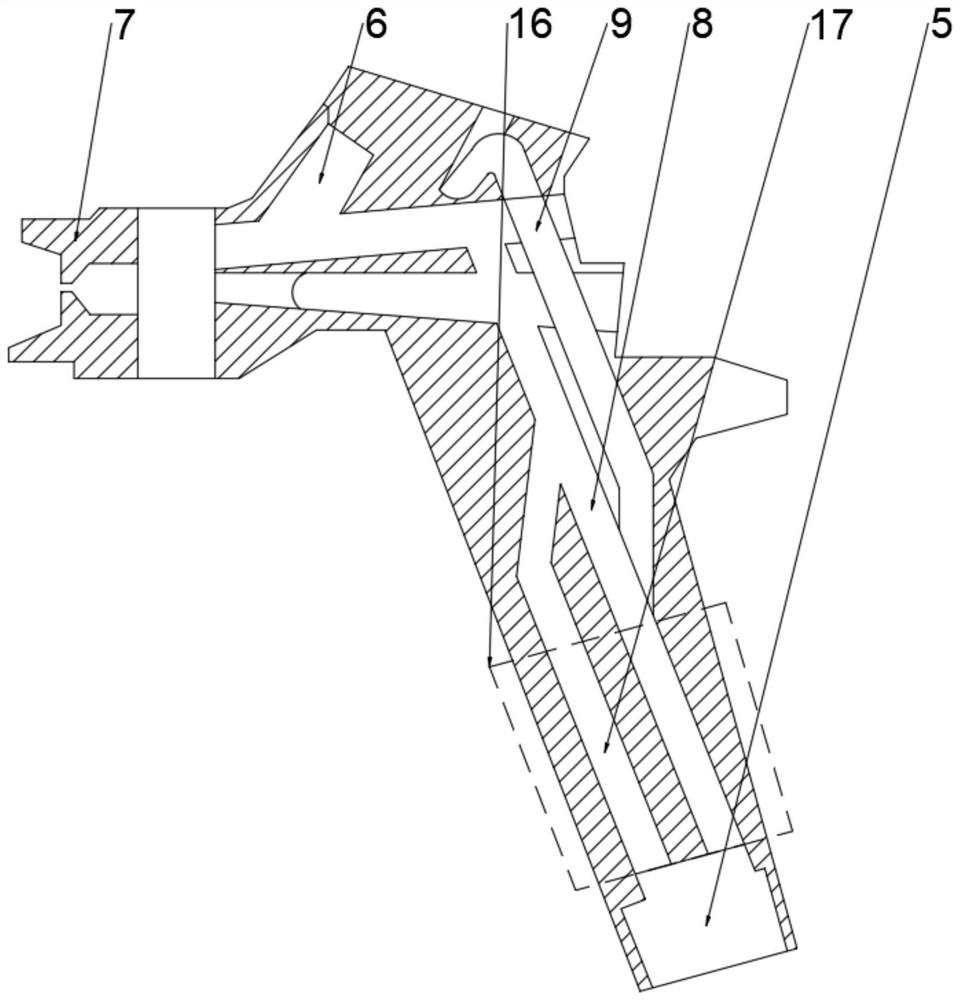

[0032] refer to Figure 1-2 , a spray gun for improving the service life of mold paint in metal mold casting, including a gun body 1, a paint connection structure 2, an air intake adjustment structure 3 and a central control device 4, and the paint connection structure 2 is provided with the central control device 4 The matched infrared ranging sensor 19, the bottom end of the gun body 1 is provided with an air inlet 5, the top end of the gun body 1 is provided with a paint inlet 6, and the end of the gun body 1 away from the air inlet 5 is provided. There is a nozzle 7, the air inlet 5 and the nozzle 7 are connected by an air intake pipe 8, an auxiliary air pipe 9 is arranged between the air intake pipe 8 and the paint connection structure 2, and the interior of the central control device 4 An intelligent control system is provided, the paint connection structure 2 is installed at the paint inlet 6, the air intake adjustment structure 3 is installed at the air inlet 5, and th...

Embodiment 2

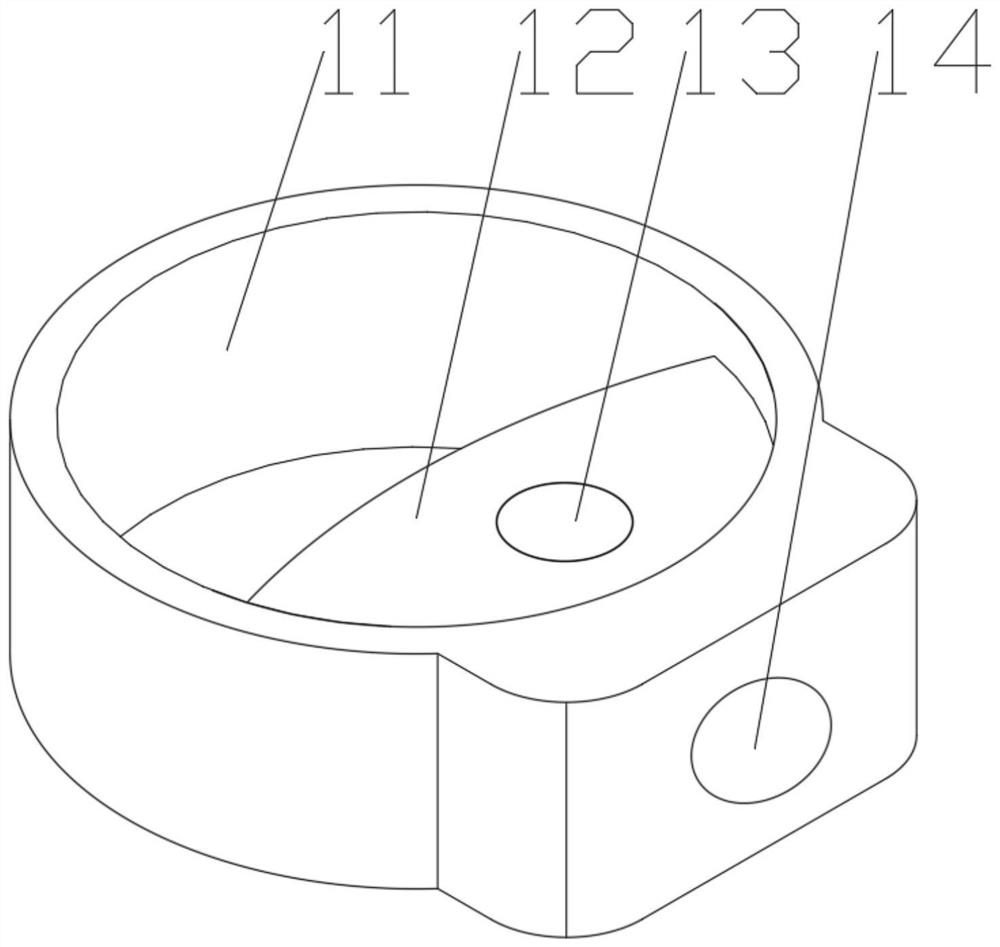

[0039] refer to Figure 1-3 , on the basis of the first embodiment, the paint connection structure 2 includes a fixed seat 10 , a connecting seat 11 is embedded in the interior of the fixed seat 10 , and the interior of the connecting seat 11 is provided with the auxiliary gas pipe 9 . The matching functional seat 12, the bottom surface of the functional seat 12 is flush with the ground of the connecting seat 11, the top surface of the functional seat 12 is 2-4 cm away from the top surface of the connecting seat 11, and the functional seat 12 A connecting hole 13 is opened inside.

[0040] Specifically, the connection hole 13 is an N-shaped structure, and a spare hole 14 is opened on one side of the connection hole 13 to match the functional seat 12 , and the spare hole 14 communicates with the connection hole 13 . The connecting holes 13 can be arranged to open a plurality of connecting holes 13 at equal distances within the technological scope of the functional base.

[00...

Embodiment 3

[0044] refer to Figure 1-3 , on the basis of Embodiment 1 or Embodiment 2, the air intake adjustment structure 3 includes an adjustment seat 16 , and a branch pipe 17 is arranged inside the adjustment seat 16 , and the branch pipe 17 is in phase with the air intake pipe 8 . connect.

[0045] Specifically, the outer wall of the adjustment seat 16 is provided with a blocking buckle 18 that cooperates with the branch pipe 17 and the intake pipe 8 , and the connection between the branch pipe 17 and the intake pipe 8 is located in the auxiliary gas pipe 9 is above the connection with the intake pipe 8.

[0046] It is not difficult to see from the above design that the air intake adjustment structure 3 can play the role of replacing and enhancing the air inlet 5. By setting up the branch pipe 17, when the high-pressure air pipe is connected, the port of the branch pipe 17 and the port of the air inlet 5 can both carry out air flow, forming two air flow paths that can be backflowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com