Impeller elastic washer and high-continuity small-torsion coaxial connector containing same

A technology of elastic washer and impeller, which is applied in the direction of clamping/spring connection, connection, two-part connection device, etc. It can solve the problems of unguaranteed product quality and production efficiency, jamming, high precision requirements, etc., and achieve processing and connection The effect of speeding up device assembly, reducing precision requirements, and continuously improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

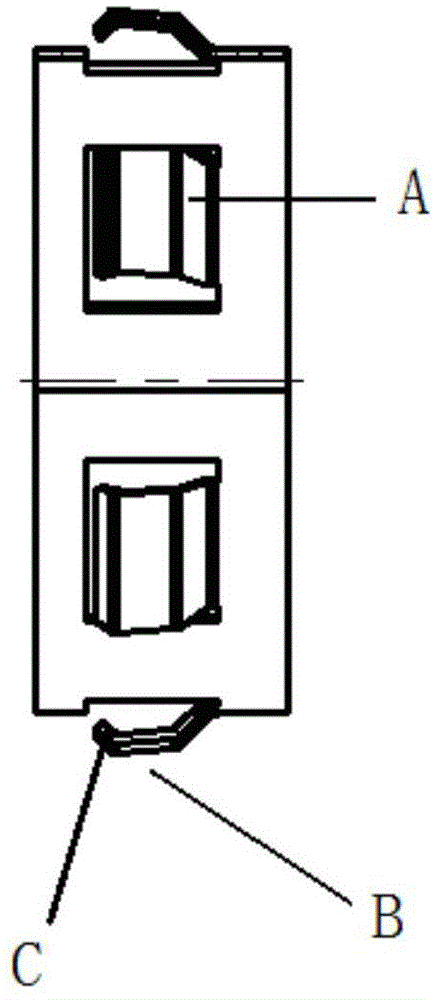

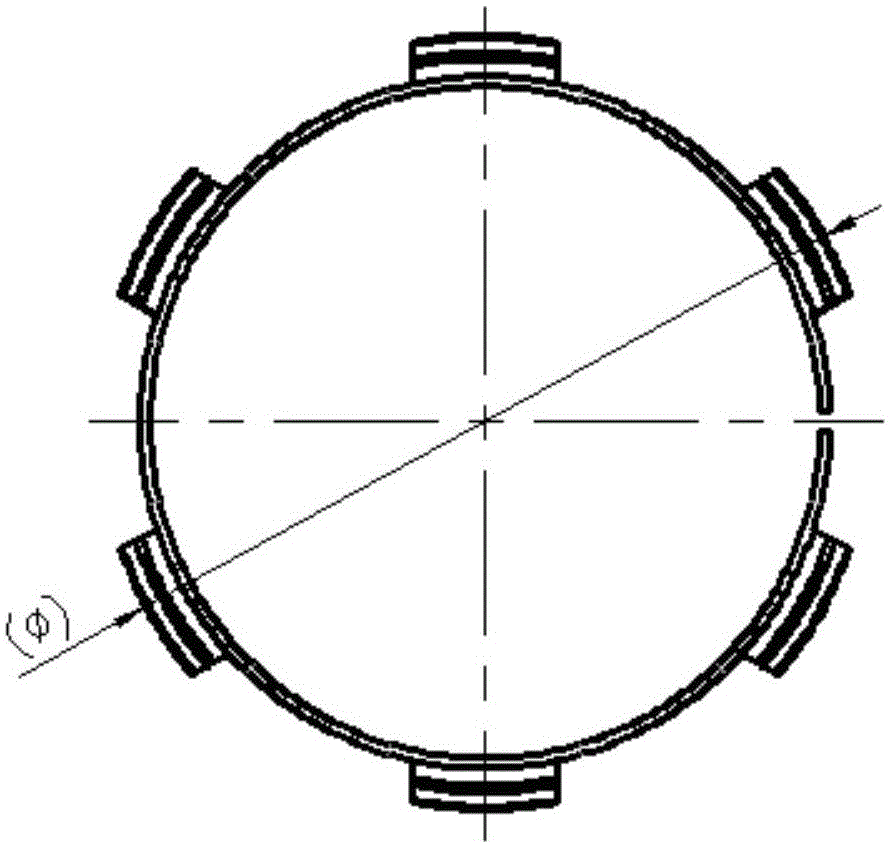

[0024] As shown in Figure 2, the elastic washer of the impeller is formed by bending one side of the elastic rectangular conductive material strip to the opposite side to form a circular body. Several impellers are uniformly stamped on the rectangular conductive material strip, and each impeller is backed at the same angle. It protrudes outward toward the central axis of the annular body, one side of the impeller is connected to the rectangular conductive strip, and the remaining sides of the impeller are separated from the rectangular conductive strip.

[0025] Preferably, there are 6 groups of impellers, and the distance between the centers of two adjacent groups of impellers is 60°. Each group of impellers includes A rotating surface, B rotating surface, and C rotating surface sequentially connected to the rectangular conductive strip.

[0026] The surface of revolution A is a curved surface formed by rotating the straight generatrix A around the central axis of the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com