A liquid egg pasteurization system

A pasteurization and egg liquid technology, applied in the field of egg liquid pasteurization system, can solve the problems of unsuitable for handling high viscosity materials, complicated structure of tubular sterilization unit, limitation of continuous sterilization time, etc., to avoid pollution and ensure The effect of continuous safe production and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

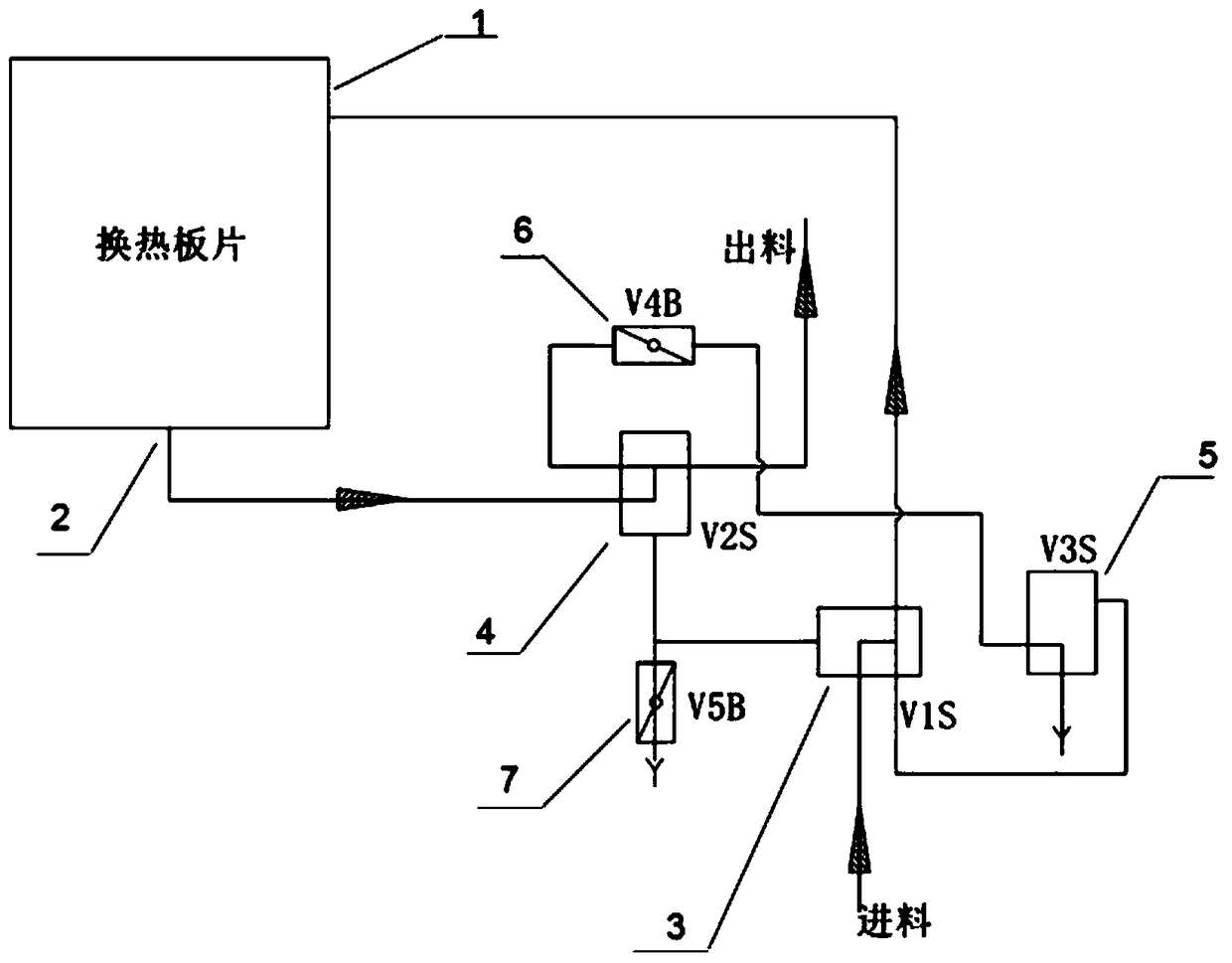

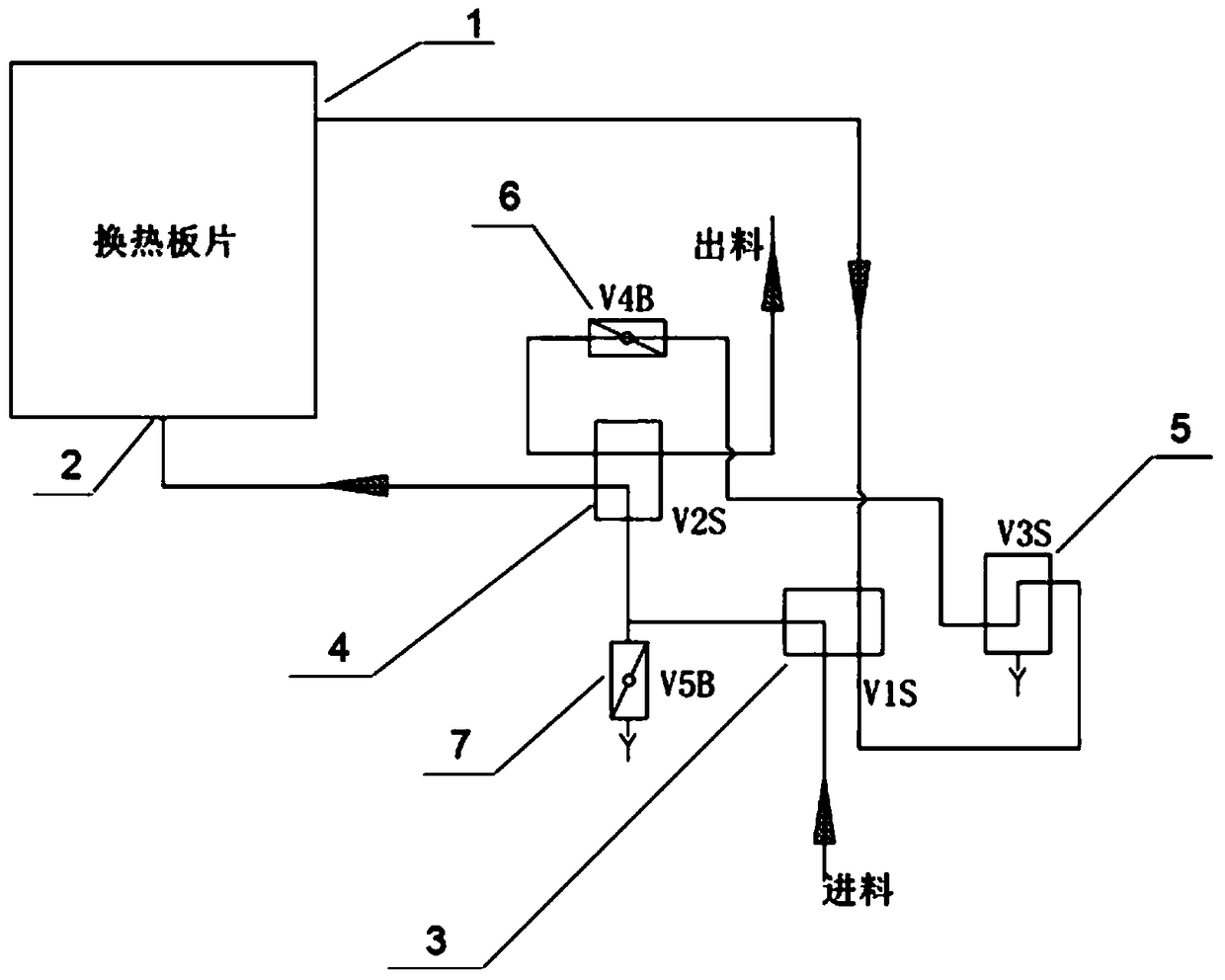

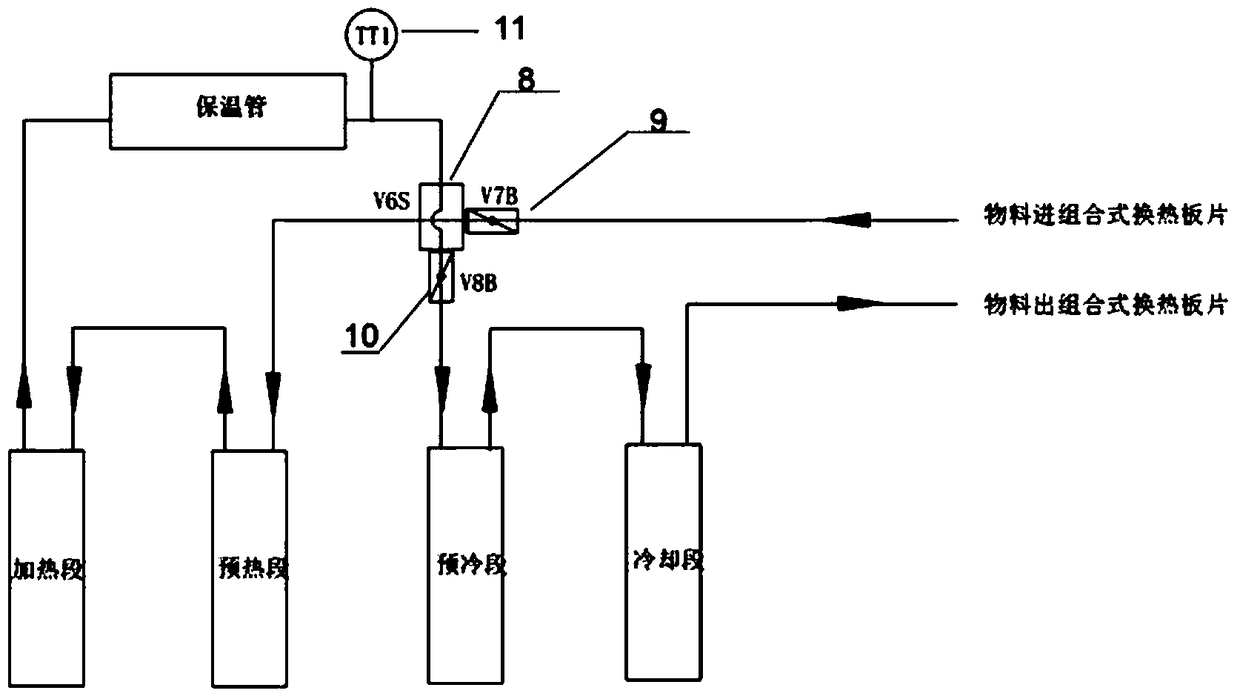

[0024] Embodiment 1 liquid egg pasteurization system

[0025] The liquid egg pasteurization system of this embodiment mainly includes a high-pressure homogenizer, a balance tank, a combined heat exchange plate, a heat preservation coil, heating accessories, energy recovery accessories, a power pump, and a pneumatic valve group. All parts are connected by sanitary stainless steel pipes. Install temperature sensors, conductivity sensors, pressure sensors, volume flow meters and other sensors at corresponding positions as required.

[0026] The high-pressure homogenizer is used to homogenize the egg liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com