Processing technology of plastic-steel zipper

A processing technology and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems affecting the appearance of clothing, arching of chain teeth, shortening of size, etc., to achieve good shaping effect, improve flatness, and product quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

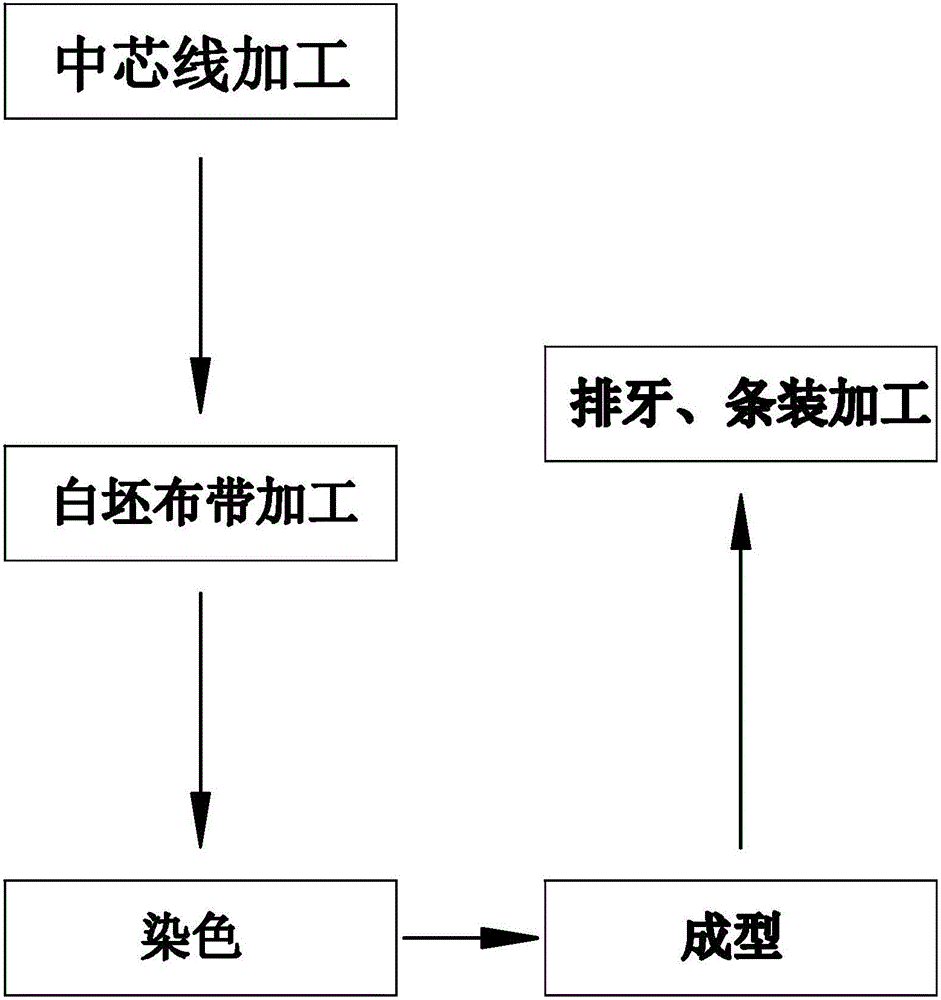

[0030] Such as figure 1 Shown, the processing technology of this plastic-steel slide fastener, this technology comprises the following steps:

[0031] A. Center line processing: The multi-strand fiber thread is processed into the center line of the rope through an ordinary center line gear forming machine. During the processing, the forming gear in the center line gear forming machine is replaced with a large number of teeth. Ordinary gear, because the number of teeth is large, the center line with a certain degree of softness is finally obtained, and the softness of the center line is adjusted by changing the original ordinary gear with a small number of teeth into an ordinary gear with a large number of teeth; the fiber thread in step A is polyester The use of this material can make the core thread have better shrinkage performance. At the same time, the use of polyester thread can also greatly reduce its production cost, and the production cost is low; in step A, weave an e...

Embodiment 2

[0037] Such as figure 1 Shown, the processing technology of this plastic-steel slide fastener, this technology comprises the following steps:

[0038] A. Center line processing: The multi-strand fiber thread is processed into the center line of the rope through an ordinary center line gear forming machine. During the processing, the forming gear in the center line gear forming machine is replaced with a large number of teeth. Ordinary gear, because the number of teeth is large, the center line with a certain degree of softness is finally obtained, and the softness of the center line is adjusted by changing the original ordinary gear with a small number of teeth into an ordinary gear with a large number of teeth; the fiber thread in step A is polyester The use of this material can make the core thread have better shrinkage performance. At the same time, the use of polyester thread can also greatly reduce its production cost, and the production cost is low; in step A, weave an e...

Embodiment 3

[0044] Such asfigure 1 Shown, the processing technology of this plastic-steel slide fastener, this technology comprises the following steps:

[0045] A. Center line processing: The multi-strand fiber thread is processed into the center line of the rope through an ordinary center line gear forming machine. During the processing, the forming gear in the center line gear forming machine is replaced with a large number of teeth. Ordinary gear, because the number of teeth is large, the center line with a certain degree of softness is finally obtained, and the softness of the center line is adjusted by changing the original ordinary gear with a small number of teeth into an ordinary gear with a large number of teeth; the fiber thread in step A is polyester The use of this material can make the core thread have better shrinkage performance. At the same time, the use of polyester thread can also greatly reduce its production cost, and the production cost is low; in step A, weave an emp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com