High-effective gas-water separator

A gas-water separator and high-efficiency technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of energy consumption and waste, high power consumption, etc., and achieve reliable performance, simple structure, high efficiency and stable gas-water The effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

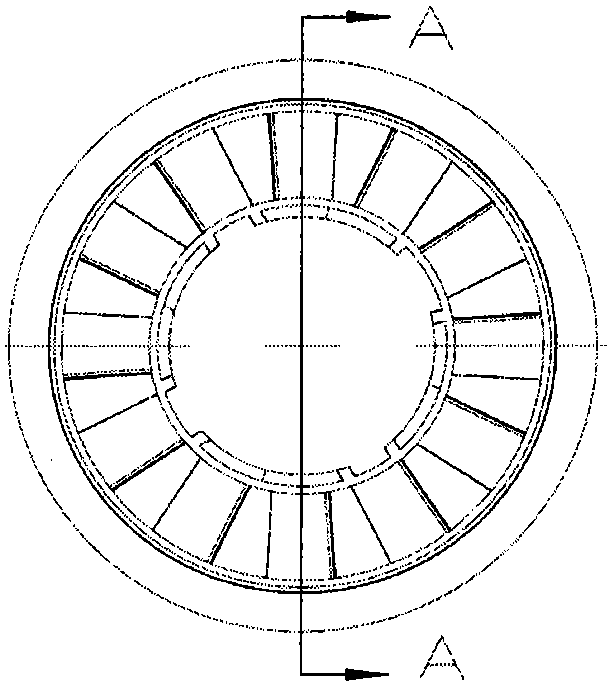

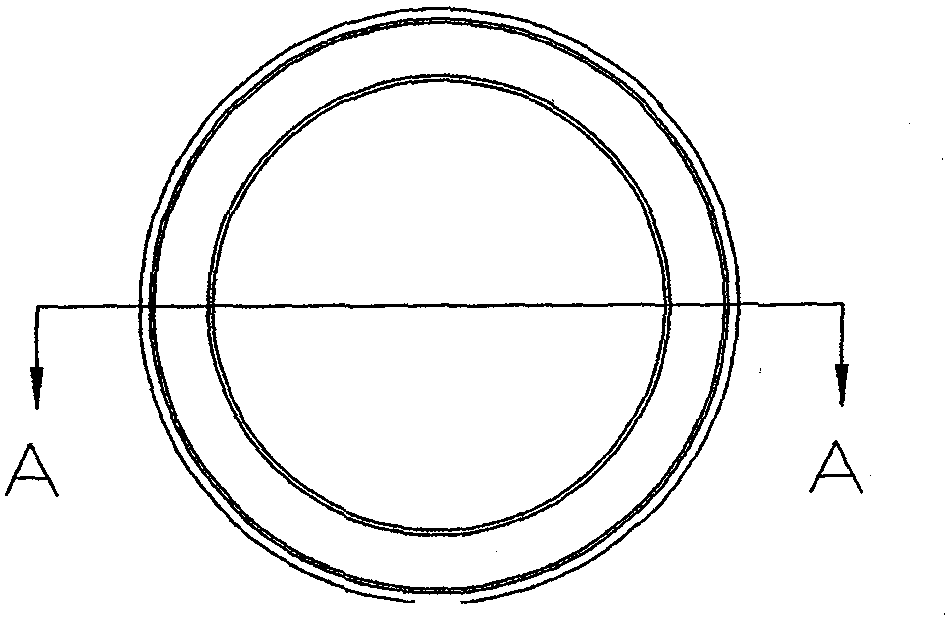

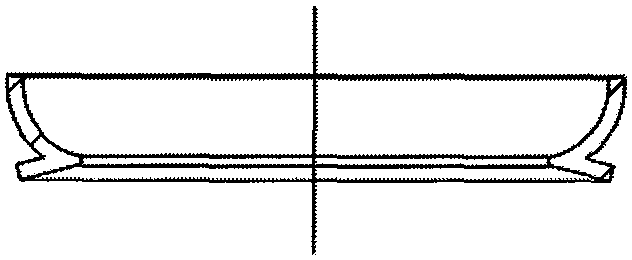

[0035] High-efficiency gas-water separator of the present invention such as Figure 1-Figure 11 As shown, it includes the guide part 2, the cross section of the guide part 2 is a trumpet-shaped structure, the upper port of the guide part 2 is sealed and connected with the inner tube of the pipe head 6 through a sealed connection, and the middle part is provided with a secondary separation guide groove assembly position The lower port is designed with an inner circle and an outer groove cylinder; the water mist and oil mist collector 4 is installed on the secondary separation diversion groove 3 to form a sealing groove and realize a low flow rate separation device; The separation diversion groove 3 is further designed with an interception and condensation groove to form a secondary collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com