A method and device for preparing a nano-dispersion system

A nano-dispersion and system technology, applied in chemical instruments and methods, mixers with rotary stirring devices, and drilling compositions, etc. problem, to achieve good stability and easy injection, improve sweep efficiency, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

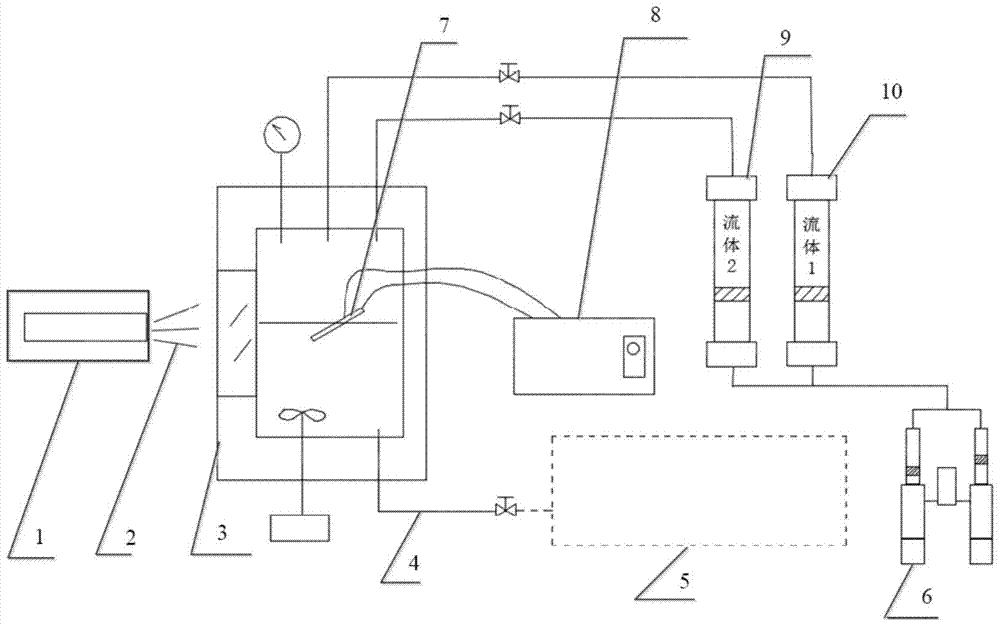

[0051] This embodiment provides a device for preparing a nano-dispersion system, the structure of which is as follows: image 3 shown.

[0052] The device includes an electron scattering source 1, a system reaction generating container 3, an agitator 302, a transducer sheet 7, an ultrasonic generator 8, an intermediate container and a displacement pump 6, and the transducer sheet 7 is placed in the system reaction generating container 3 , the ultrasonic generator 8 is placed outside the system reaction generating container 3, and the transducer sheet 7 is connected with the ultrasonic generator 8 through a wire 705;

[0053] The structure of the system reaction generating container 3 is as follows Figure 4 As shown, it includes a visible end cover 301 and a kettle body 304, the visible end cover 301 is placed on the side of the kettle body 304, and is pressed on the kettle body 304 by an O-shaped sealing ring; the visible end cover 301 is provided with a glass block 305; th...

Embodiment 2

[0059] The present embodiment provides a kind of method utilizing the device in embodiment 1 to prepare nano-dispersion system, it comprises the following steps:

[0060] 1) Fill water and CO respectively in the first intermediate container 10 and the second intermediate container 9 2 ;

[0061] 2) Inject the water in the first intermediate container 10 into the system reaction generating container 3, and when the distance from the liquid level to the bottom of the glass block 305 accounts for 2 / 3 of the height of the entire glass block 305, stop injecting water, and place the second intermediate CO in vessel 9 2 Inject into the system reaction generation container 3, make the temperature in the system reaction generation container 3 reach the design value (the temperature is 50 ℃), by continuously injecting CO 2 The pressure in the system reaction generating container 3 is raised to the design value (10MPa);

[0062] 3) Turn on the stirrer 302 and stir for 1h to make the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com