Method for obtaining antifriction and wear-resistant workpiece surface through lasers

A workpiece surface, laser technology, applied in the field of friction pair lubrication, can solve problems such as difficult machining, affecting the surface roughness of the friction pair, and shortening the fatigue life of the friction pair surface, so as to improve wear resistance, reduce friction, and improve fatigue life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0024] A method for obtaining the surface of a friction-reducing and wear-resistant workpiece by using a laser, comprising the following steps:

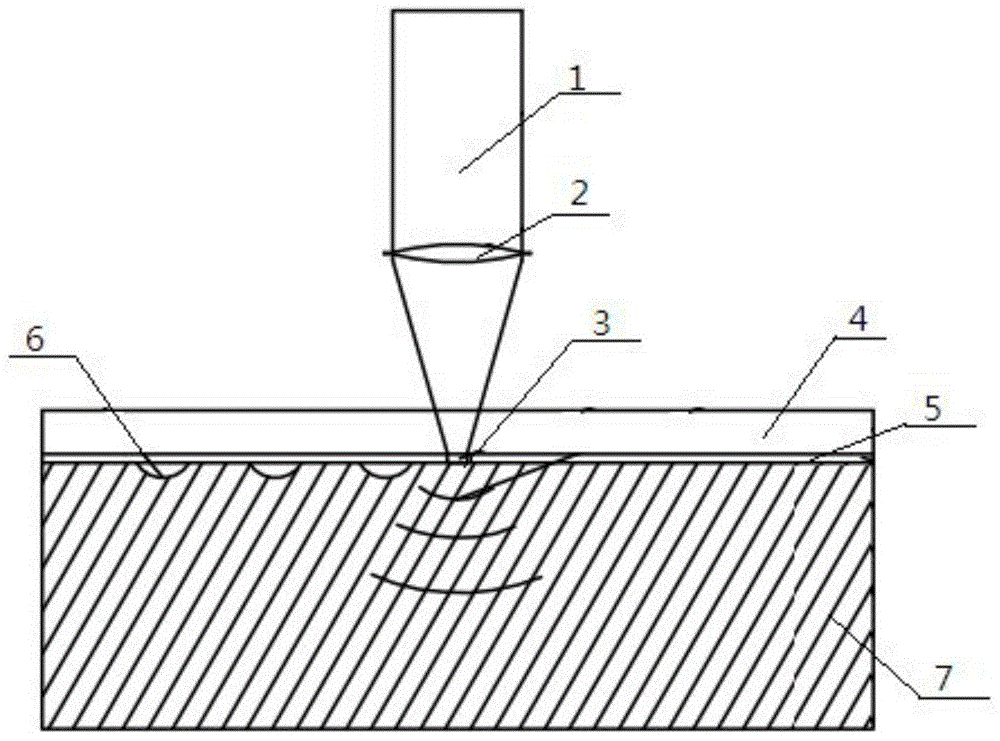

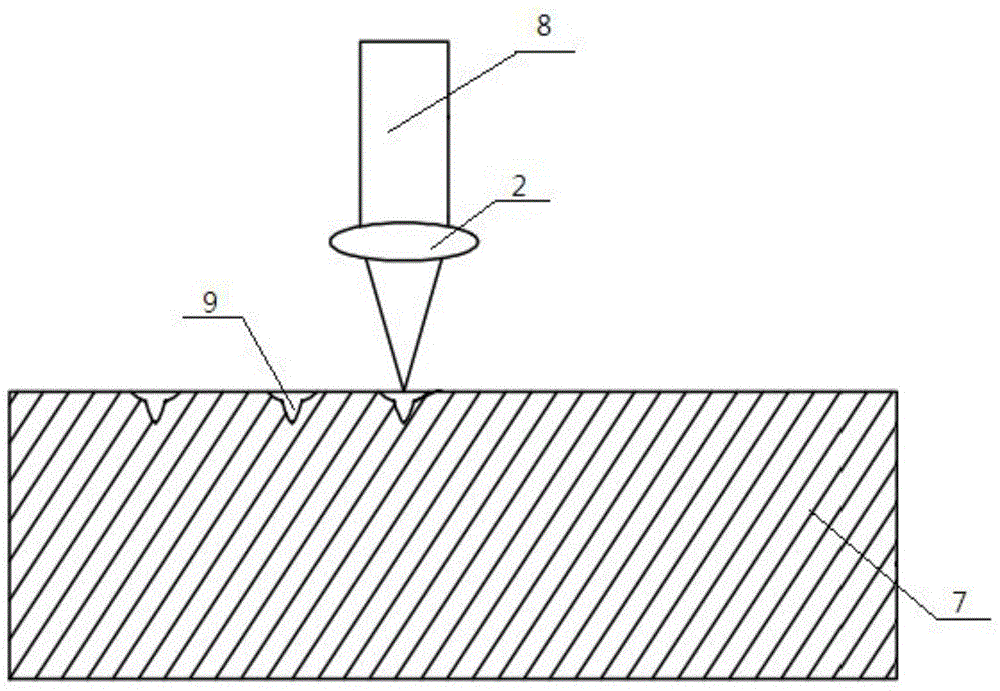

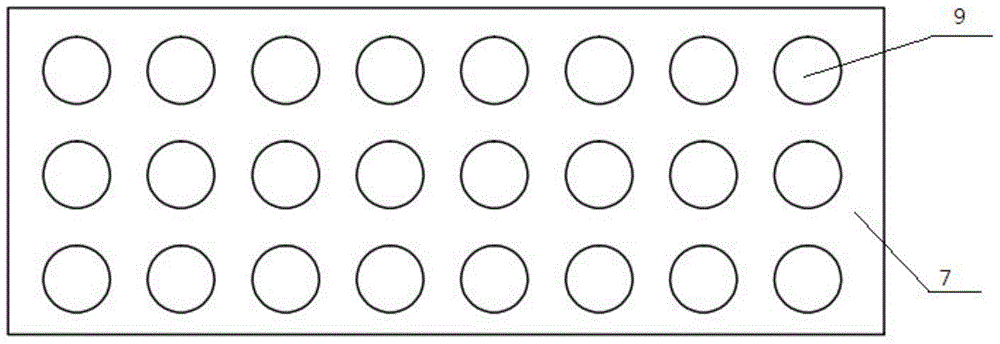

[0025] Step A: laser microshock treatment; as figure 1 As shown, the absorbing layer 5 is coated on the surface of the workpiece 7, and then the constraining layer 4 is covered on the absorbing layer 5. The absorbing layer is black insulating tape with a thickness of 0.5mm; the constrained layer is K9 glass with a thickness of 1mm; according to the workpiece The diameter D of the microhole 9 required on the surface of 7 adjusts the process parameters of the laser; then the laser is driven so that the laser shock beam 1 is focused by the focusing lens 2 and then irradiates the surface of the workpiece 7 to obtain a micropit 6 who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com