An air-feather airflow directional aircraft

A technology of aircraft and wings, which is applied in the field of air-feather airflow directional aircraft, and can solve problems such as the complexity of the transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

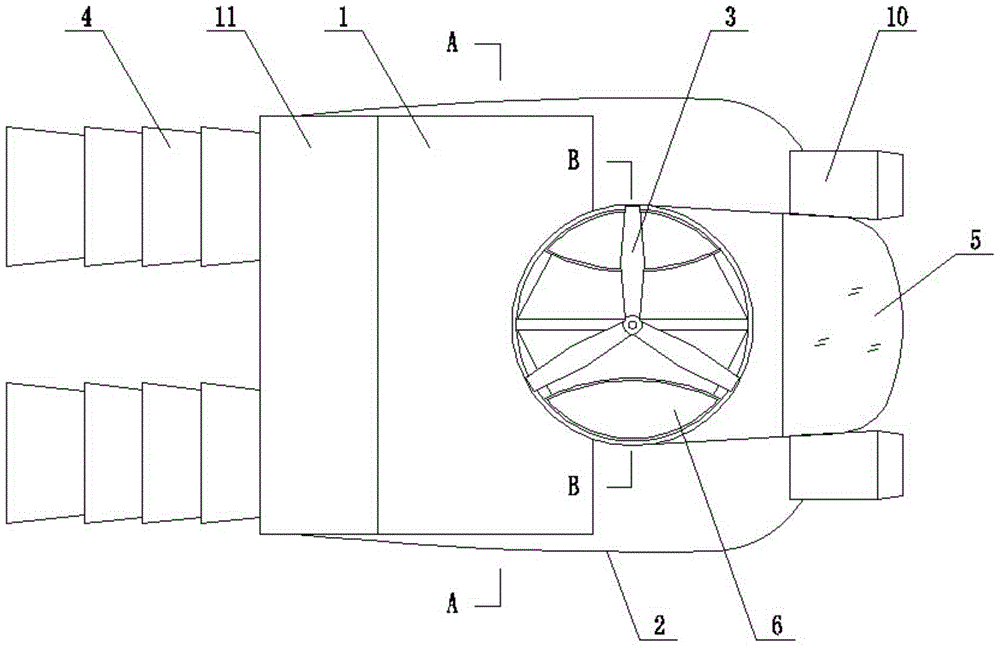

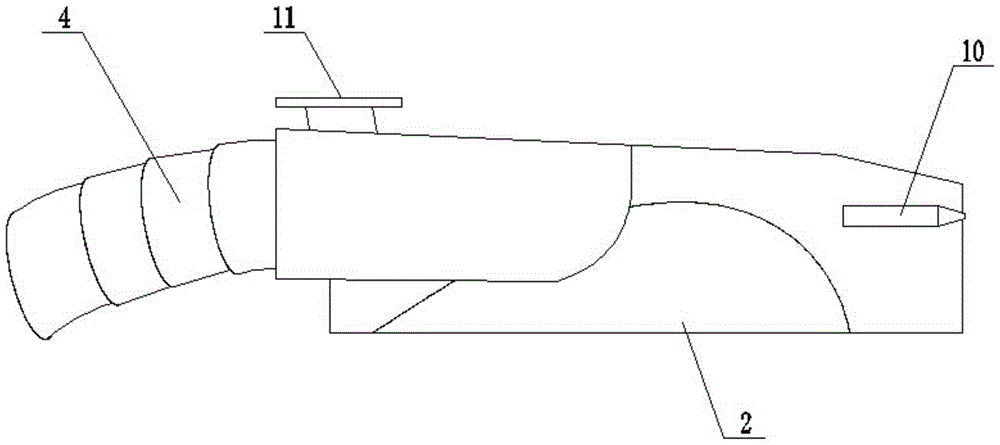

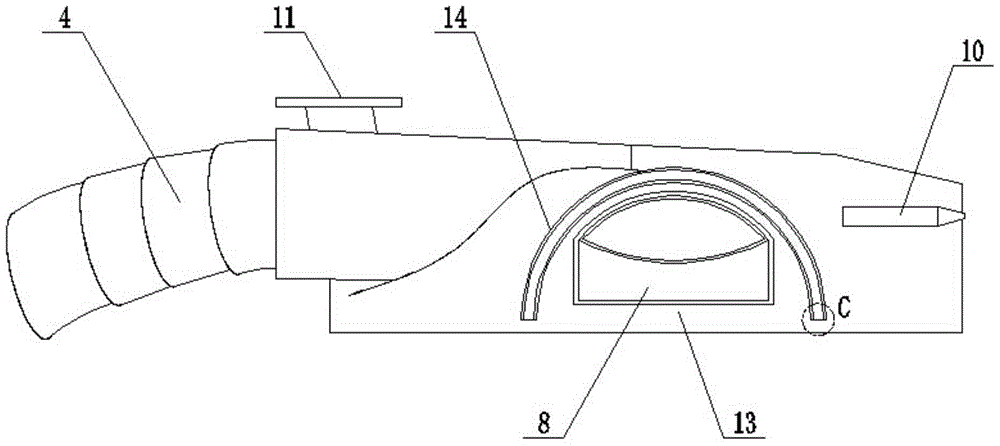

[0033] refer to Figure 1 to Figure 6, the air-wing type airflow directional aircraft includes a body 1, a control room 5, a lifting system and a propulsion system, the lifting system includes a wing-shaped wing 2, a lifting duct 6 and a propeller 3, and the control room 5 is located at The front part of the body 1 is provided with a central control system, a power transmission system, various monitoring instruments and a satellite positioning system, etc., the lifting duct 6 is located in the middle of the body 1, and the propeller 3 is located in the lifting duct 6 Inside, the lifting duct 6 is located below the propeller 3 and is provided with a herringbone-shaped air compartment plate 7 in the longitudinal section. connection, the shock absorber is connected with the piston engine or turboshaft engine located in the control room 5, the propeller 3 is a coaxial reverse propeller, and the side walls of the left and right sides of the lifting duct 6 are symmetrically provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com