A kind of sodium manganese water purification material and preparation method and application thereof

A technology of water purification and hydrothermal reaction, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as high production cost, complex synthesis process, limited depth and breadth of property understanding, and achieve Easy to break, good catalytic oxidation activity, good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

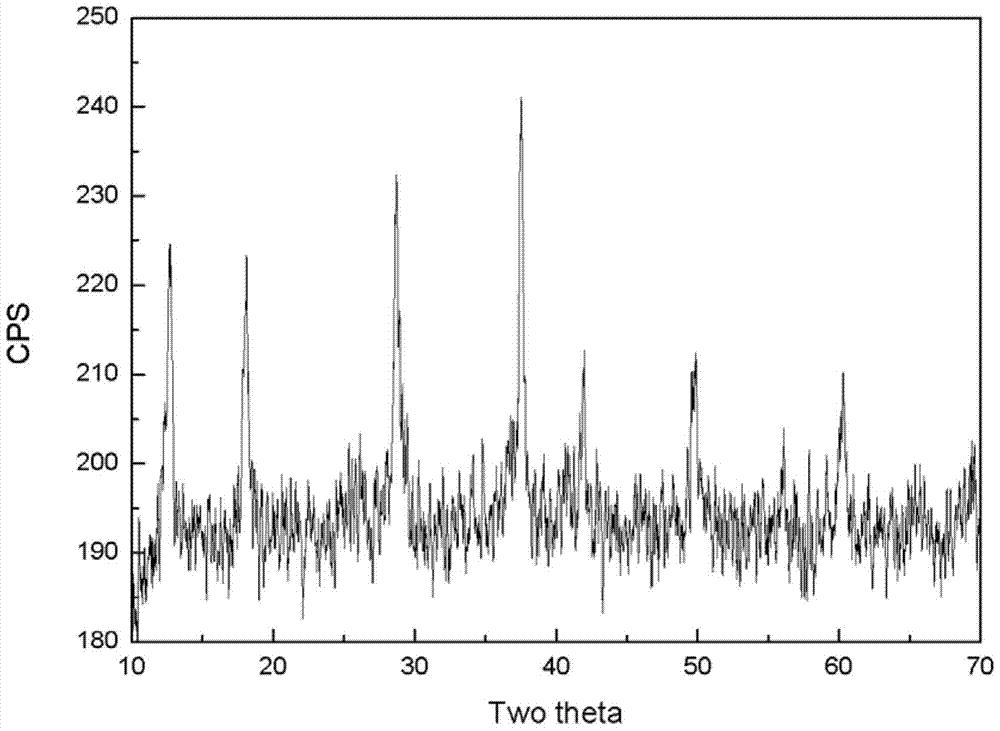

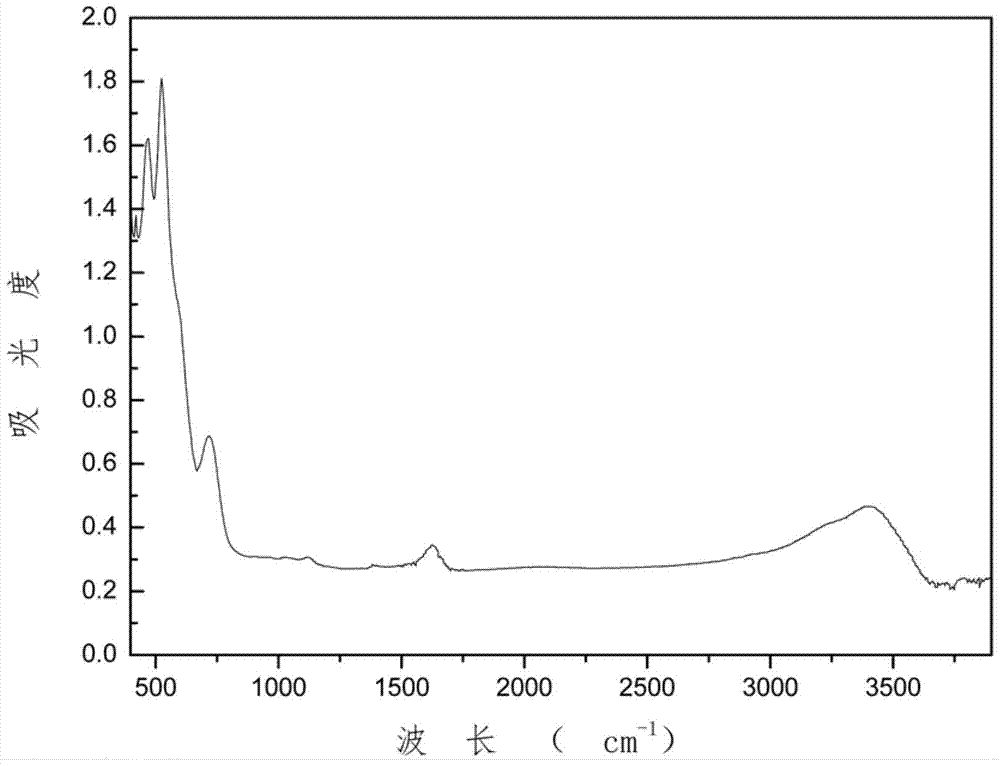

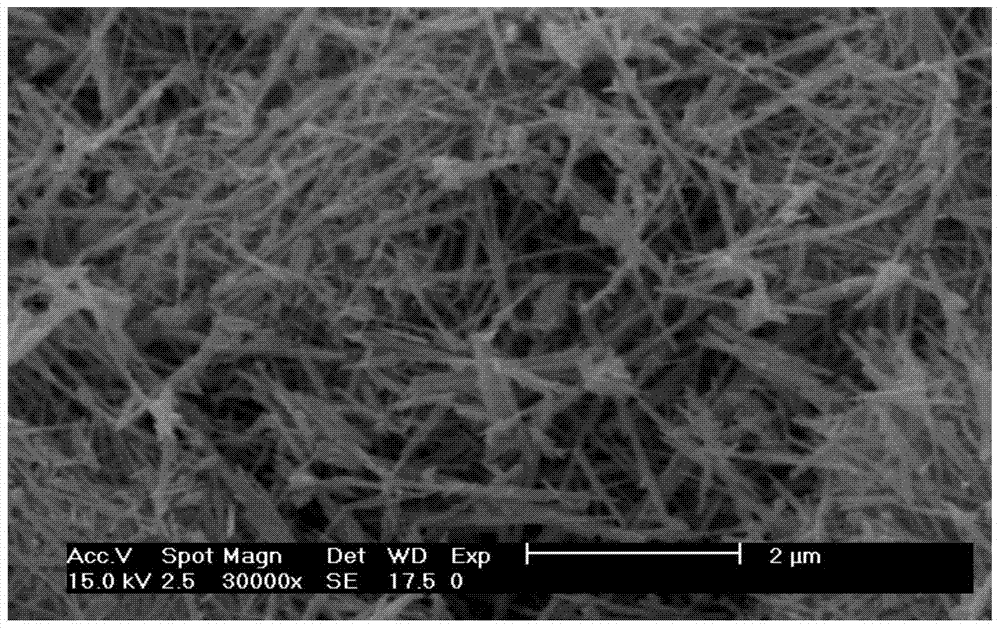

[0040] In a 500ml reaction kettle, add 12g potassium permanganate, 8g manganese ore crude product, 150ml deionized water, and then add 6g H 2 o 2 , then stir evenly, add 20ml of phosphoric acid-sodium dihydrogen phosphate buffer solution (concentration is 1mol / L), and adjust the pH value to 1 with 15mol / L concentrated nitric acid, and seal the reaction vessel. Heating and reacting at 120°C for 12 hours, then cooling to room temperature with water, adding a small amount of deionized water, standing and aging for 3 hours, filtering and washing until the pH of the filtrate is 6.5-7.0, drying and calcining at 450°C for 1.5 hours, and obtaining the product after crushing Invention of water purification materials. The obtained sample grows in a rod-like structure, and the crystallites are agglomerated; after testing, its X-PRD is as follows: figure 1 As shown, its infrared spectrum is shown as figure 2 As shown, its high-resolution scanning electron microscope image is shown as ...

Embodiment 2

[0042] In a 500ml reaction kettle, add 4g of potassium permanganate and 4g of manganese ore crude product, 150ml of deionized water, and then add 4g of H 2 o 2 , then stir and dissolve, add 16ml of phosphoric acid-sodium dihydrogen phosphate buffer solution (concentration is 1.5mol / L), and adjust the pH to about 2.0 with 15mol / L concentrated nitric acid, and seal the reaction kettle. Heating and reacting at 150°C for 20 hours, then cooling to room temperature with water, adding a small amount of deionized water, standing and aging for 12 hours, filtering and washing until the pH value of the filtrate reaches 6.5-7.0, drying and calcining at 430°C for 1 hour, and crushing to obtain The water purification material of the present invention. After testing, its X-PRD and figure 1 Basically the same, its infrared spectrum and figure 2 Basically the same, its high-resolution scanning electron microscope image and image 3 Basically the same.

Embodiment 3

[0044] In a 500ml reaction kettle, add 8g of potassium permanganate and 4g of manganese ore crude product, 150ml of deionized water, and then add 2g of H 2 o 2 , stir evenly, add 10ml of phosphoric acid-sodium dihydrogen phosphate buffer solution with a concentration of 1mol / L, and adjust the pH to about 1.0 with 15mol / L concentrated nitric acid, and seal the reaction kettle. Heating and reacting at 100°C for 10 hours, then cooling to room temperature with water, adding a small amount of deionized water, standing and aging for 5 hours, filtering and washing until the pH value of the filtrate reaches 6.5-7.0, drying and calcining at 400°C for 2 hours, and crushing to obtain The water purification material of the present invention. After testing, its X-PRD and figure 1 Basically the same, its infrared spectrum and figure 2 Basically the same, its high-resolution scanning electron microscope image and image 3 Basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com