A honeycomb fiber filter

A fiber filter and honeycomb technology, which is applied in the field of honeycomb fiber filters, can solve the problems that the sewage interception capacity cannot be fully utilized, the variable porosity cannot be realized, and the water head loss is large, so as to protect normal operation and service life, reduce The effect of backwash water volume and long working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

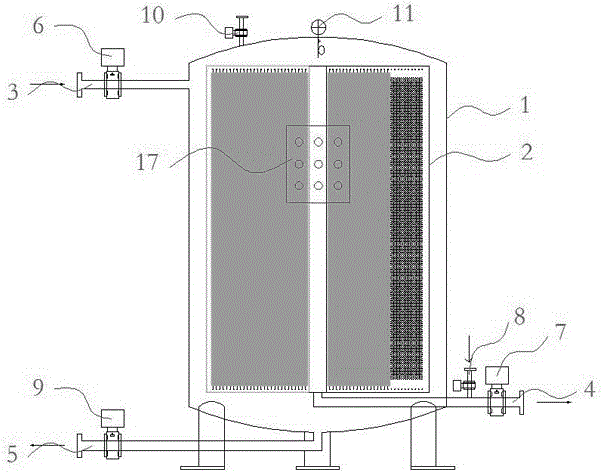

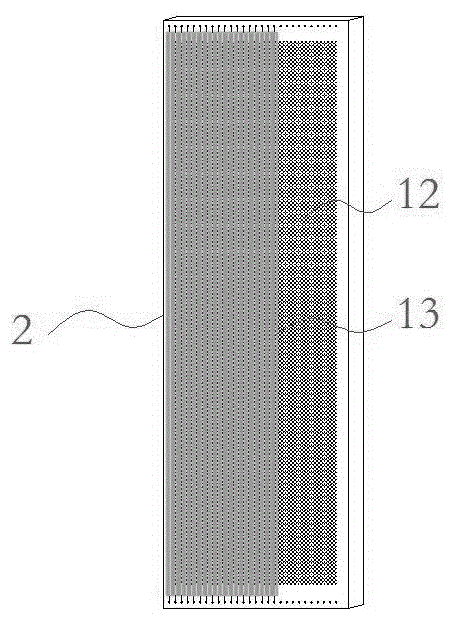

[0014] The honeycomb fiber filter of the present invention is composed of a cylinder body (1), a honeycomb porous plate radially installed in the cylinder, and a filter core device vertically hanging on the surface of the honeycomb porous plate.

[0015] Cylinder (1) and water inflow pipe (3) and inflow control valve (6), filtered water discharge pipe (4) and discharge control valve (7), air flow control valve on the compressed air inflow pipe (8) It is connected with the discharge valve (10) on the compressed air discharge pipe, as well as the backwash water discharge pipe (5) and the backwash water discharge control valve (9); a pressure sensor (11) is installed on the upper end of the filter to sense The pressure inside the cylinder (1); the front of the cylinder (1) is equipped with a control panel, and the user can manually adjust the water filtration or backwashi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com