Glass production wastewater treatment apparatus

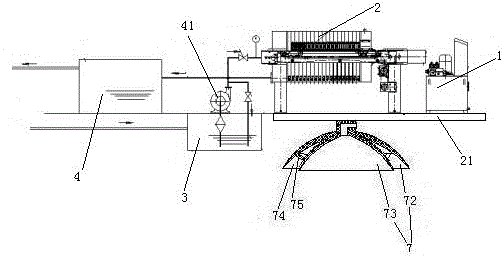

A technology for producing wastewater and treatment devices, which is applied in ceramic wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] Embodiment two, the difference with embodiment one is:

[0043] see Figure 4 , The lower end of the filter press control box 1 is provided with a supporting foot 11. The fixing structure 7 is disposed on the supporting foot 11 . The filter press control box 1 is a quadrilateral column. The front, rear, left, and right sides of the filter press control box 1 are all provided with connection holes 13 . An insect-proof plate 14 is connected to the connecting hole 13 . The lower end of the insect-proof board 14 is connected with a raised board 15 . Connecting ears 141 are provided at both horizontal ends of the lower end of the insect-proof plate 14 . Both ends of the heightening plate 15 in the horizontal direction are provided with hinge shafts 151 . The hinge shaft 151 is rotatably connected in the connecting ear 141 to hinge the heightening plate 15 and the insect-proof plate 14 together.

[0044] see Figure 5 , the upper end of the heightening plate 15 is inc...

Embodiment 3

[0068] Embodiment three, the difference with embodiment two is:

[0069] see Figure 14 , the rotating shaft 51 is pierced with a circular inner rod 511 . The inner rod 511 is a tubular structure. The inner surface of the rotating shaft 51 is provided with an inner friction layer 512 . The inner rod 511 includes a left rod 5111 and a right rod 5112 . The outer peripheral surfaces of the left rod 5111 and the right rod 5112 are provided with an outer friction layer 5113 . The outer friction layer 5113 covers the inner rod 511 along the circumference of the inner rod 511 . The left end of the left rod 5111 is connected with the rotating shaft 51 through the left energy-absorbing spring 513 . The right end surface of the left rod 5111 is provided with a plurality of first reversing teeth 5114 distributed along the circumferential direction of the left rod. The right end of the right rod 5112 is connected with the rotating shaft 51 through the right energy-absorbing spring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com