Intelligent control technique for sludge continuous deep dewatering

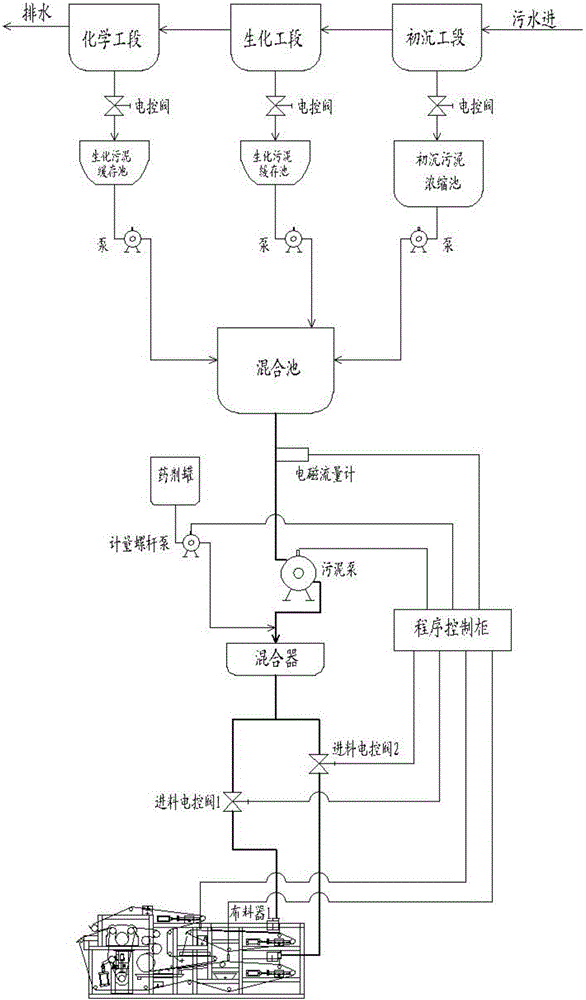

A technology of deep dehydration and process method, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of different sludge volume, uncertain discharge time, and affecting the normal operation of equipment, so as to improve treatment efficiency and overcome adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

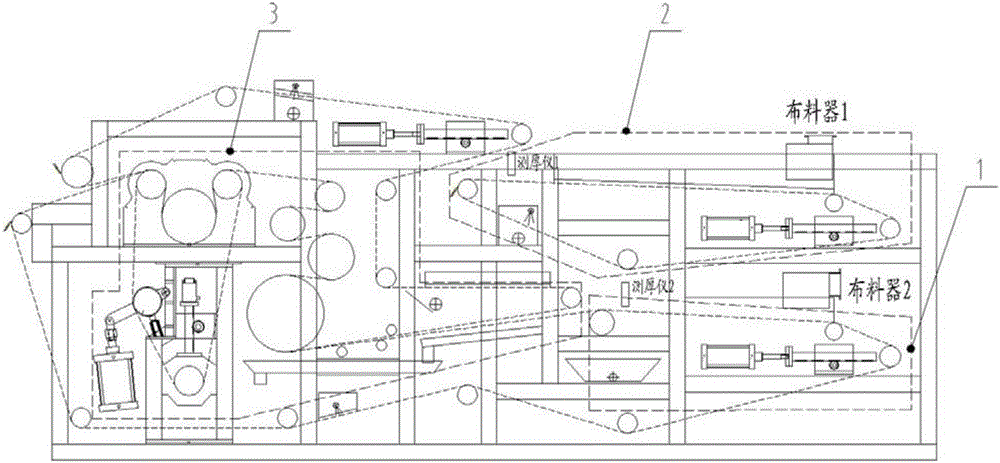

[0063] Example 1: Three kinds of low-concentration sludge with a solid content of 1-3% produced in the water treatment section (primary sludge concentration 3%, biochemical sludge concentration 2.4%, chemical sludge concentration 2.2%), respectively Simultaneously pump from the thickening tank and two buffer tanks to the mixing tank through their respective lift pumps, of which the amount of primary sludge is 650-750T / D, the amount of biochemical sludge is 380-450T / D, and the amount of chemical sludge is 280-340T / D D, The parameters of the three pumps to the mixing tank are: flow rate 150 cubic meters per hour, head 50 meters. The pumping time of the primary sedimentation tank is set to 15 minutes / time, the pumping time of biochemical mud is set to 12 minutes / time, the pumping time of chemical mud is set to 10 minutes / time, and the overall interval time is 14-18 minutes, taking the primary sedimentation time as Benchmark, the sludge pump parameter flow rate is 100 cubic meters...

Embodiment 2

[0064] Example 2: Three kinds of low-concentration sludge with a solid content of 1-3% produced in the water treatment section (primary sludge concentration 3%, biochemical sludge concentration 2.0%, chemical sludge concentration 2.1%), respectively Pumping from the thickening tank and two buffer tanks to the mixing tank at the same time through their respective lift pumps, the amount of primary sludge is 450-550T / D, the amount of biochemical sludge is 380-440T / D, and the amount of chemical sludge is 80-130T / D D, The parameters of the three pumps to the mixing tank are: flow rate 120 cubic meters per hour, head 80 meters. The pumping time of the primary sedimentation tank is set to 12 minutes / time, the pumping time of biochemical mud is set to 10 minutes / time, the pumping time of chemical mud is set to 5 minutes / time, and the overall interval is 6-10 minutes. Benchmark, the sludge pump parameter flow rate is 100 cubic meters per hour and the head is 80 meters. Since the pumpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com