A kind of glass lens with sapphire surface layer and preparation method thereof

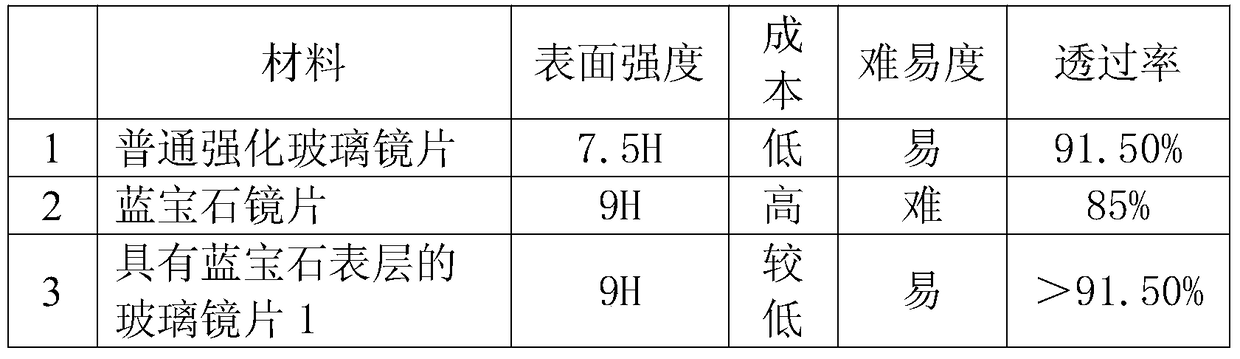

A glass lens and sapphire technology, which is applied in the field of glass lens preparation, can solve the problems of low glass hardness and high cost of sapphire lenses, achieve high light transmittance, avoid adverse effects, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of the glass lens 1 with the sapphire surface layer is as follows:

[0018] Using metal aluminum as a target, nitrogen as a sputtering gas, a glass lens as a substrate, and oxygen as a reactive gas, the target is sputtered to form a sapphire film on the substrate. The sapphire The thin film is an aluminum oxide thin film, wherein the deposition temperature is controlled to be 400° C., the deposition total pressure is 0.8 Pa, and the oxygen partial pressure is 2%.

[0019] The target material is non-doped high-purity metal aluminum with a purity of 99.99%.

[0020] The purity of the oxygen is 99.99%, and the purity of the nitrogen is 99.99%.

Embodiment 2

[0022] The preparation method of the glass lens 2 with a sapphire surface layer uses metal aluminum as a target material, nitrogen as a sputtering gas, a glass lens as a substrate, and oxygen as a reactive gas to sputter the target material so that the A sapphire film is formed on the substrate, and the sapphire film is an aluminum oxide film, wherein the deposition temperature is controlled to be 600° C., the deposition total pressure is 3.0 Pa, and the oxygen partial pressure is 6%.

[0023] The target material is non-doped high-purity metal aluminum with a purity of 99.99%.

[0024] The purity of the oxygen is 99.99%, and the purity of the nitrogen is 99.99%.

Embodiment 3

[0026] The preparation method of the glass lens 3 with a sapphire surface layer uses metal aluminum as a target material, nitrogen gas as a sputtering gas, a glass lens as a substrate, and oxygen as a reactive gas to sputter the target material so that the A sapphire film is formed on the substrate, and the sapphire film is an aluminum oxide film, wherein the deposition temperature is controlled to be 500° C., the deposition total pressure is 2.0 Pa, and the oxygen partial pressure is 4%.

[0027] The target material is non-doped high-purity metal aluminum with a purity of 99.99%.

[0028] The purity of the oxygen is 99.99%, and the purity of the nitrogen is 99.99%.

[0029] The prepared glass lens 1 with a sapphire surface, the glass lens 2 with a sapphire surface, and the glass lens 3 with a sapphire surface not only enhance the surface hardness of the glass, but also greatly reduce the cost, and also break the low production capacity of the sapphire lens. Limitations, can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap