A vacuum multi-disk washing machine

A technology of pulp washing machine and vacuum, which is applied in the direction of washing/replacing pulp treatment liquid, pulp dehydration, etc., can solve the problems of unsatisfactory pulp washing effect of vacuum multi-disk thickener, and achieve the effect of saving water and improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

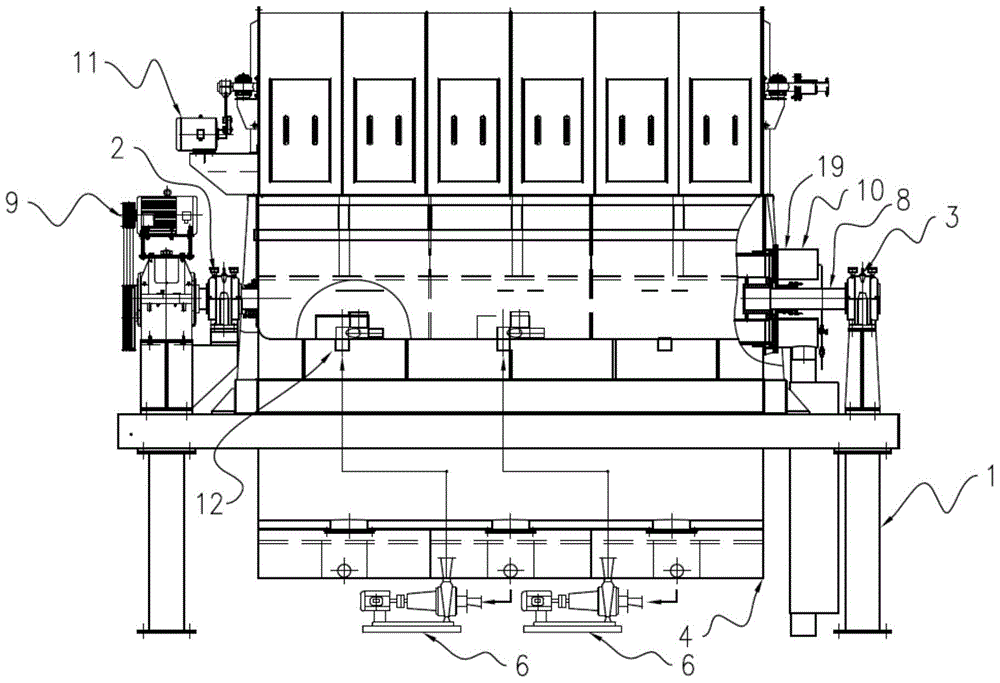

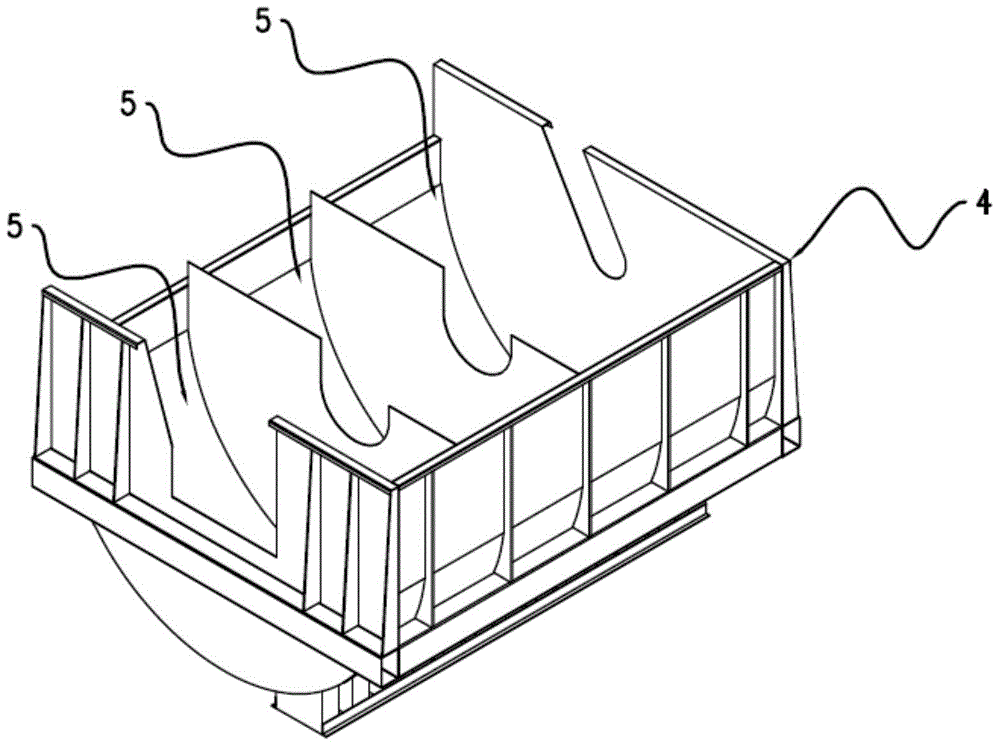

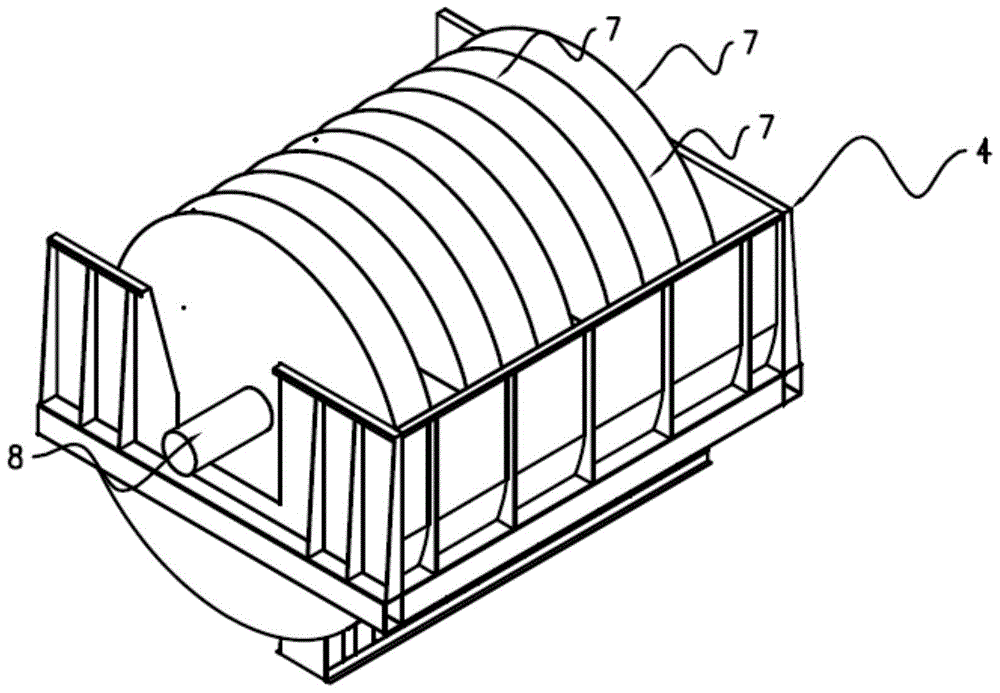

[0047] see Figure 1 to Figure 7 , the present invention provides a vacuum multi-disk washer, such as figure 1 As shown, a frame 1 is included, a transmission side bearing device 2 is provided on one side of the frame 1, and a distribution valve side bearing device 3 is provided on the other side of the frame. The frame 1 is provided with a multi-stage pulp washing area 4, such as figure 2 , 4 As shown, each section of the pulp washing area includes a pulp washing tank 5, the pulp washing tanks are separated by a partition, and the pulp washing tanks 5 are connected through the sizing system 6, and each section of the pulp washing tank is provided with a plurality of filter circles Disc 7, a plurality of filter discs are connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com