Magnetic suspension molecular pump control method and system

A control method and technology for a control system, which are applied in the field of magnetic levitation molecular pump control methods and systems, can solve problems such as system hardware damage, affecting industrial production processes, and the like, so as to avoid system shutdown, damage and impact on industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

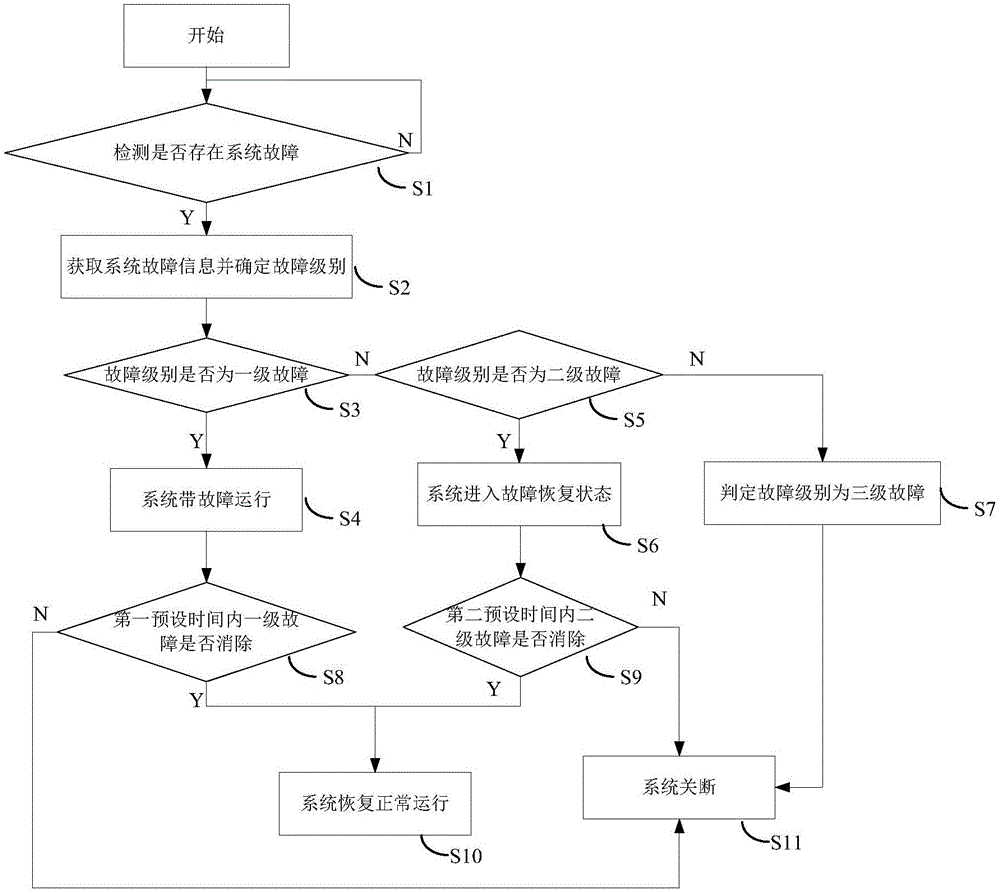

[0044] This embodiment provides a method for controlling a magnetic levitation molecular pump, such as figure 1 shown, including the following steps:

[0045] S1: Detect whether there is a system failure; if there is, go to step S2, otherwise repeat this step.

[0046] S2: Obtain system fault information and determine the fault level.

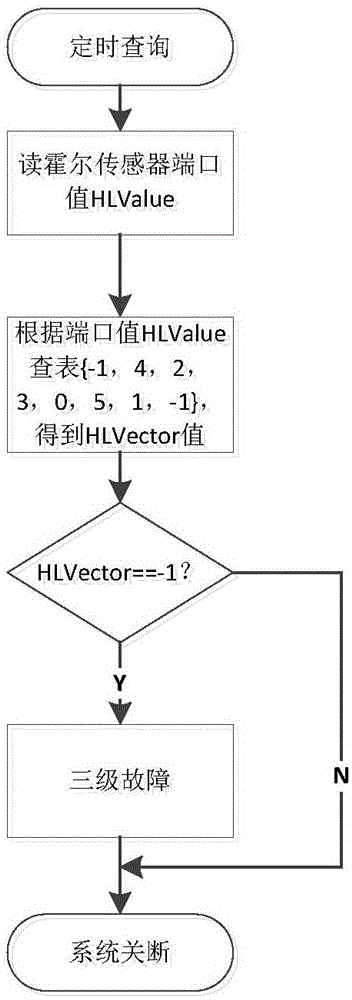

[0047] S3: Determine whether the failure level is a first-level failure, if so, go to step S4, otherwise go to step S5. The first-level fault includes the fault state of some Hall sensors; by setting the correct signal value for the faulty Hall sensor, the system can be maintained to operate with faults.

[0048] S4: The system runs with a fault, and enters step S8.

[0049] S5: Determine whether the fault level is a secondary fault, if so, go to step S6, otherwise go to step S7. The secondary faults include under-voltage faults, over-voltage faults, motor over-current faults, motor short-circuit faults, motor over-temperature faults, pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com