Leakage rate estimation system and method for product oil pipelines based on zero dimension

A technology for pipeline leakage and refined oil, which is applied in the field of dimensionless oil product pipeline leakage estimation system, can solve the problems of long distance between long-distance pipelines, inability to achieve quantitative estimation of pipeline leakage, and many environmental impact factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

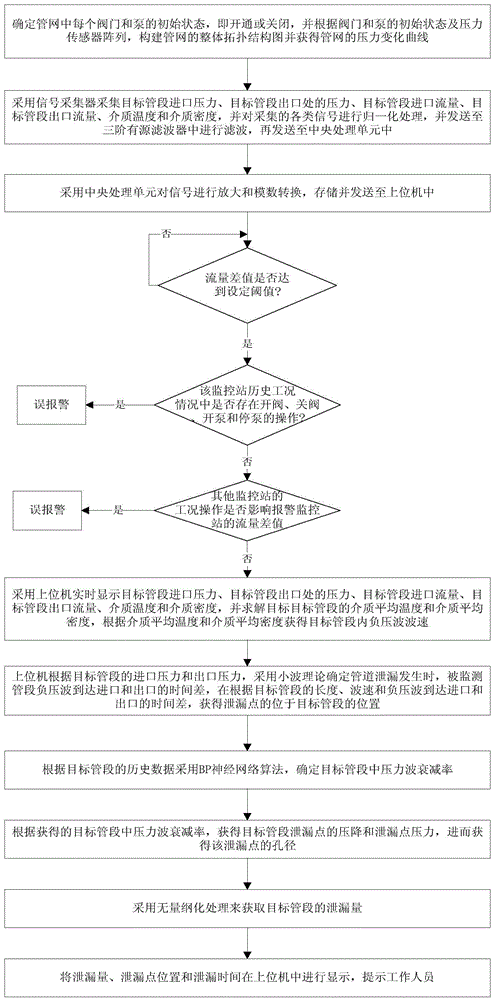

[0055] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

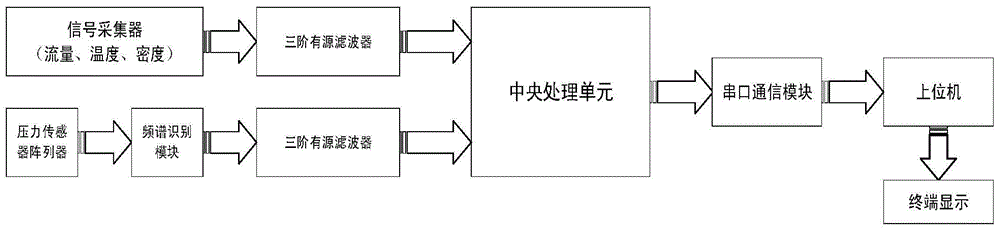

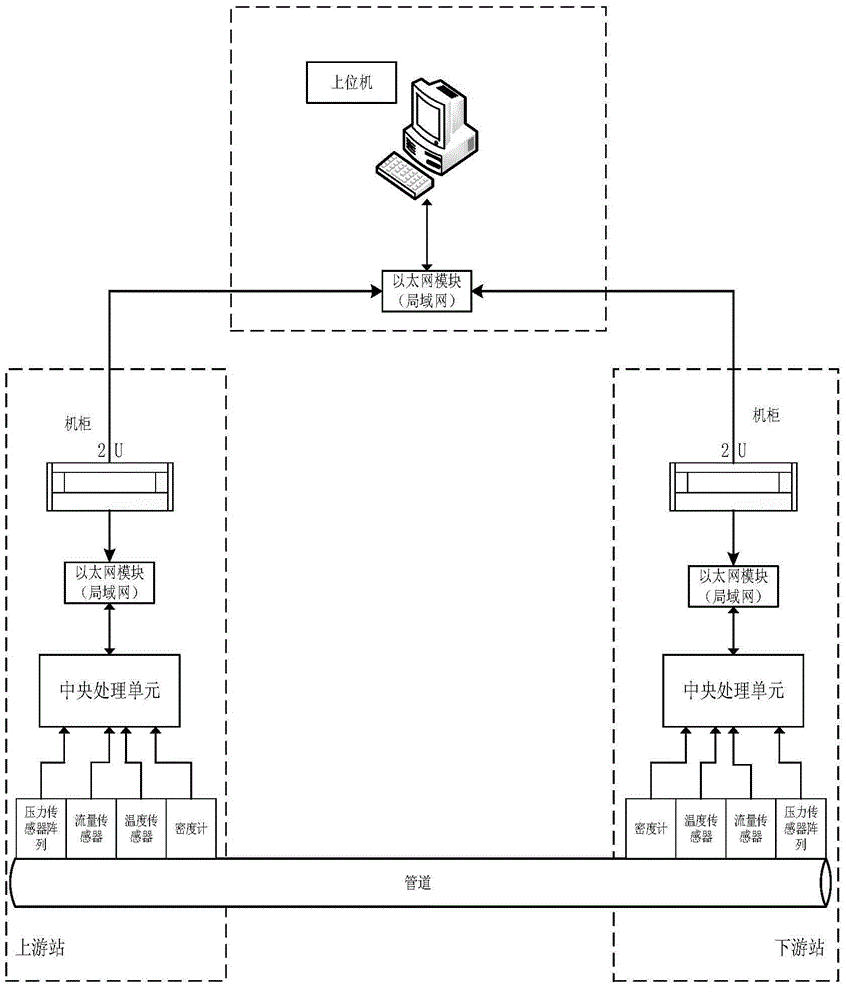

[0056] like figure 1 As shown, the embodiment of the present invention is based on a dimensionless product oil pipeline leakage estimation system. The system includes a signal collector, a pressure sensor array, a third-order active filter, a central processing unit, and a host computer; the system also includes a frequency spectrum Identification module and serial communication module;

[0057] Signal collector: used to collect the inlet pressure of the target pipe section, the pressure at the outlet of the target pipe section, the inlet flow rate of the target pipe section, the outlet flow rate of the target pipe section, the medium temperature and the medium density, and normalize the collected signals before sending to third-order active filters;

[0058] Pressure sensor array: used to measure the pressure change of the entire pipeline when the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com