Built-in composite shrinkage measuring instrument for cement-based materials

A cement-based material, embedded technology, applied in the direction of material inspection products, can solve problems such as large deviation and error measurement data, and achieve the effects of easy operation, improved measurement accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

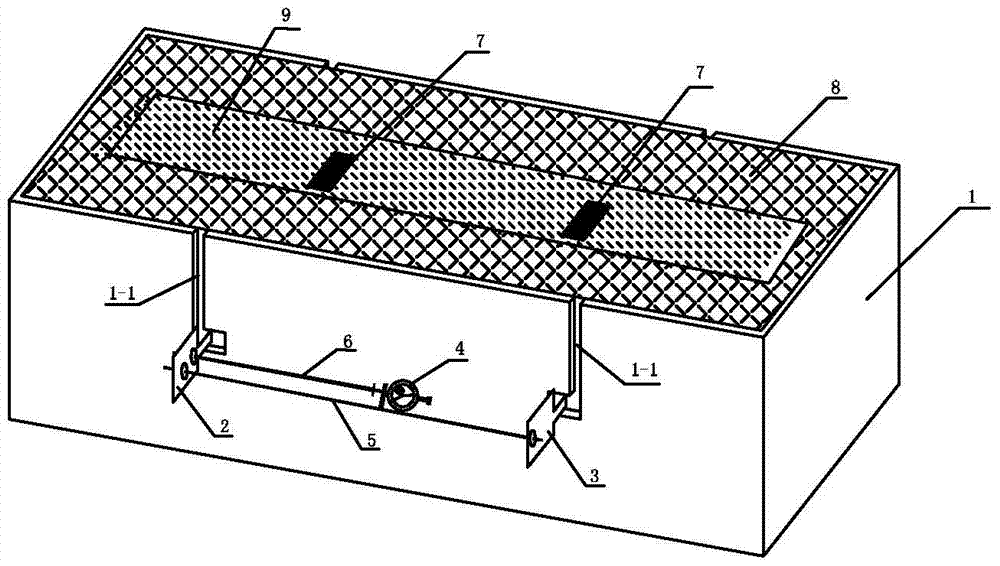

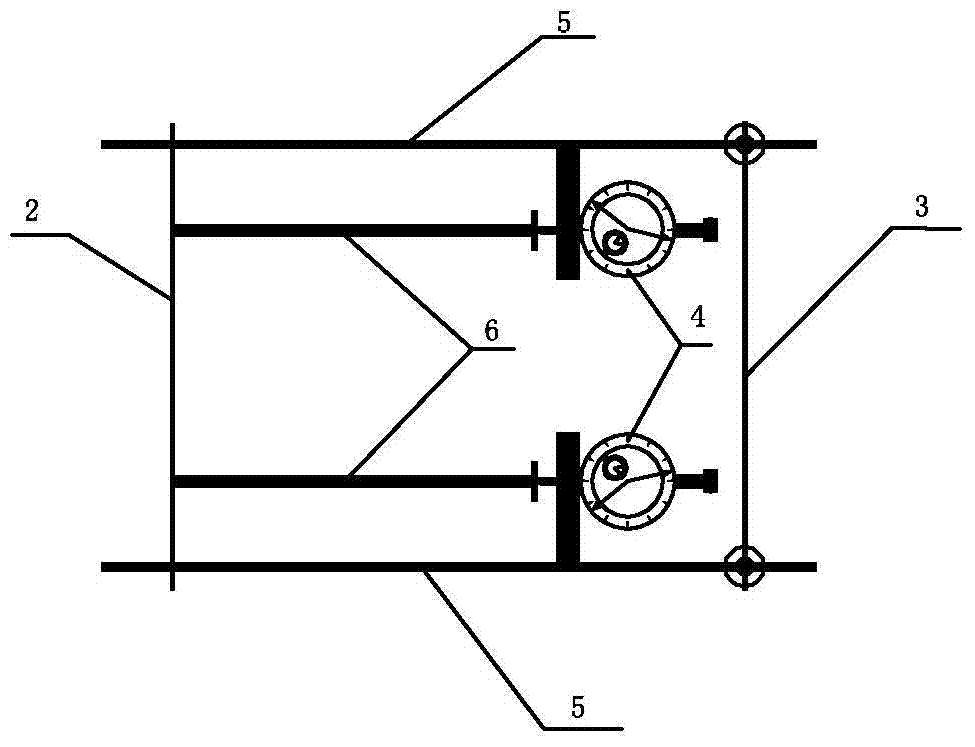

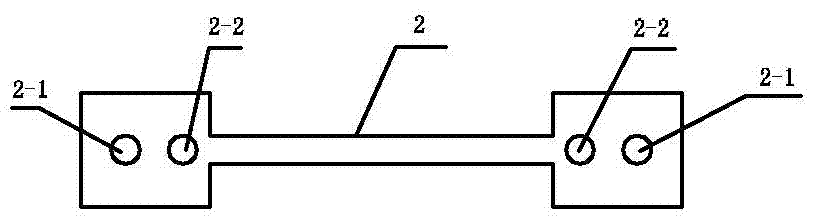

[0012] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, the embedded cement-based material composite shrinkage measuring instrument described in this embodiment includes a metal mold 1, a positioning plate 2, a placement plate 3, a measuring instrument 4, an instrument column 5, an instrument top column 6, and an inner wall isolation Layer 8 and two supporting test pieces 7, the metal mold 1 is a box with an upper opening consisting of a front side vertical plate, a rear side vertical plate, a left and right side vertical plate and a bottom plate, and an inner wall isolation layer 8 is placed in the inner cavity of the metal mold 1 On the surface of the body, two transparent L-shaped slots 1-1 are correspondingly opened on the front side vertical board and the rear side vertical board, and the two L-shaped slots 1-1 are respectively opened on the front side vertical board and the rear side vertical board. The center line of the vertical...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the embedded cement-based material composite shrinkage measuring instrument described in Embodiment 1. The measuring instrument 4, the instrument column 5 and the instrument top column 6 are respectively arranged in front of the metal mold 1 at the same time. Outside of side risers, outside of rear side risers.

[0018] The invention further improves the accuracy of the test by adopting simultaneous measurement on both sides.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 This embodiment is described. This embodiment is a further limitation of the built-in cement-based material composite shrinkage measuring instrument described in Embodiment 1. The metal mold 1 is made of stainless steel.

[0020] The metal mold 1 is made of stainless steel, fully considering that the metal mold 1 is small in shape, corrosion-resistant, and reusable, thereby reducing the cost of repurchasing the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com