Optimized design method for section of multi-rib type T-shaped beam bridge

An optimized design, T-shaped beam technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of overall stiffness reduction, excessive down deflection, flange and web cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

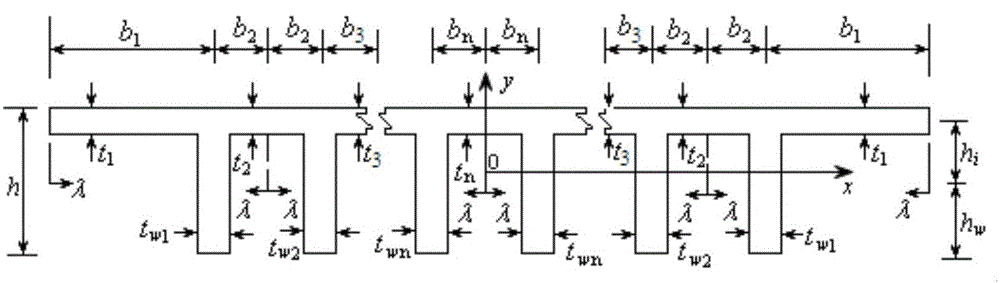

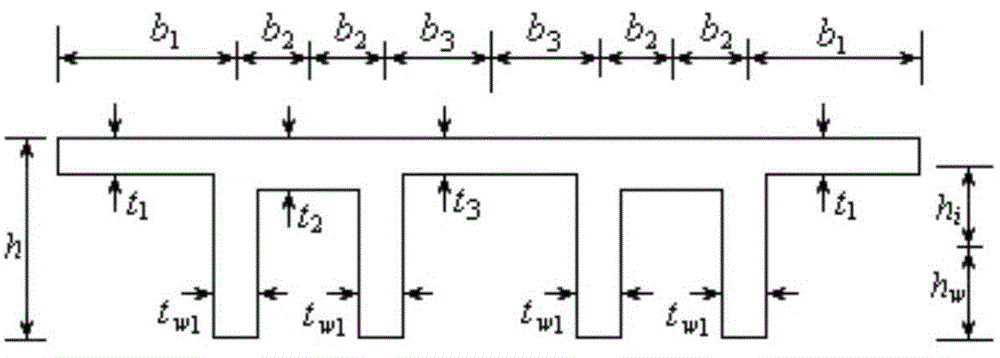

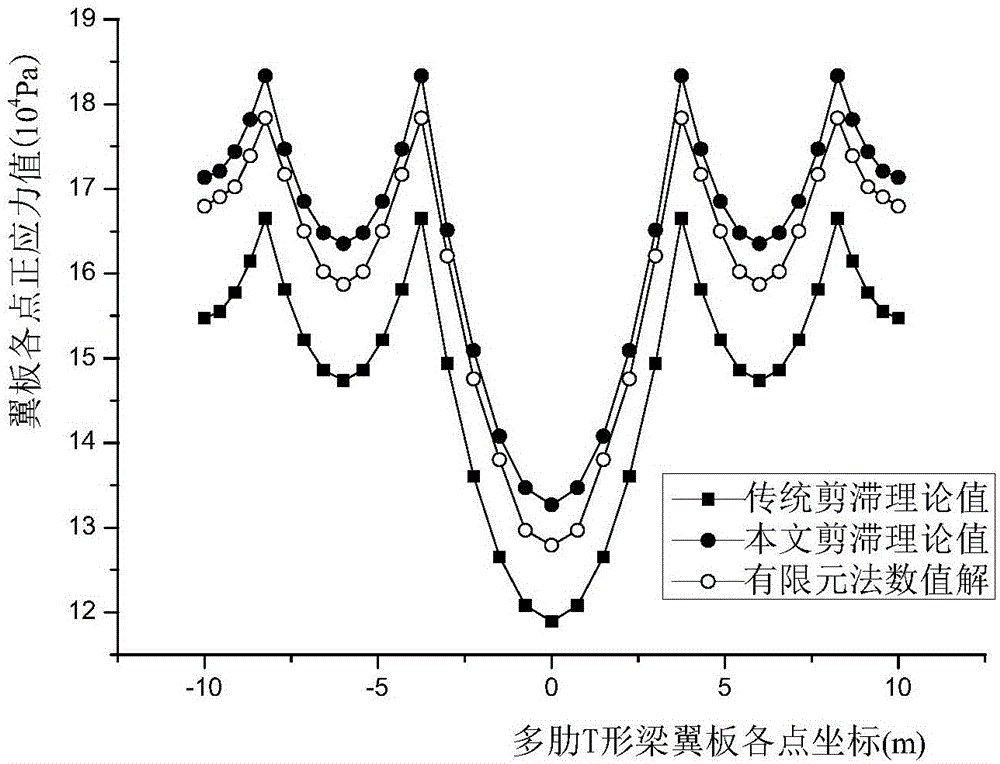

[0063] For multi-ribbed T-shaped beams, the material parameters and geometric parameters are E=3.5×10 4 MPa; G=1.5×10 4 MPa, the original design flange length is b 1 = 1.75m; b 2 =2.25m; b 3 = 3.75m; t 1 = t 2 = t 3 =0.3m, the thickness of ribs is t w =0.25m, the beam height is h=1.5m. The concentrated force P in static analysis k1 (z)=147000N, uniform force q k2 (z) = 14700 N / m.

[0064] The calculation method of stress and displacement change of multi-rib T-beam is as follows:

[0065] (1) Refer to figure 2 As shown, when n=3, according to the variational principle, the differential equation and natural boundary conditions of the multi-ribbed T-beam are:

[0066] Differential equation:

[0067] EIθ”+EI s1 u 1 "+EI s2 U' 2 '+EI s3 u 3 "-kGA(θ-w')=0(17)

[0068] EI s1 θ"+EI t1 u 1 "-Gk x1 u 1 +EI a1 U' 2 '+EI a2 U' 3 '=0(18)

[0069] EI s2 θ"+EI a1 u 1 "+EI t2 U' 2 '-Gk x2 u 2 +EI a3 u 3 "=0(19)

[0070] EI s3 θ"+EI a2 u 1 "+EI a3 U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com