A multi-level support technology and monitoring method for roadway with large impact rock pressure

A multi-level, high-impact technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve problems such as normal construction difficulties, mine mining difficulties, stress differences, etc., and achieve easy dynamic maintenance, reduce manpower, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

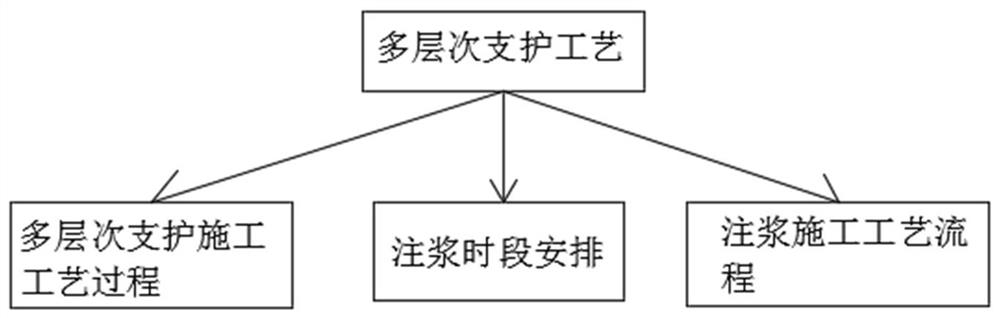

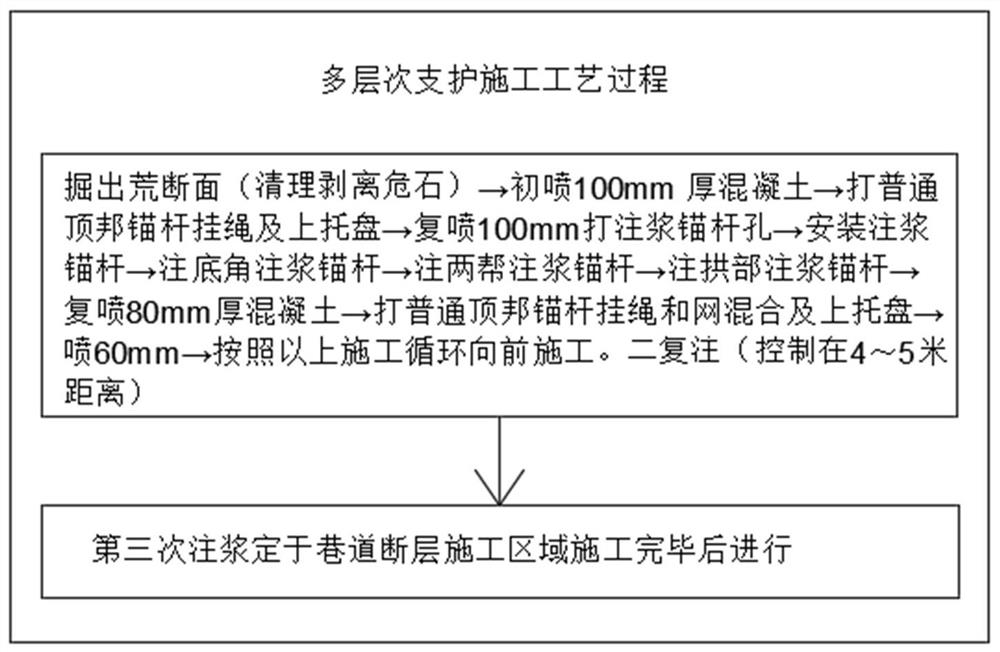

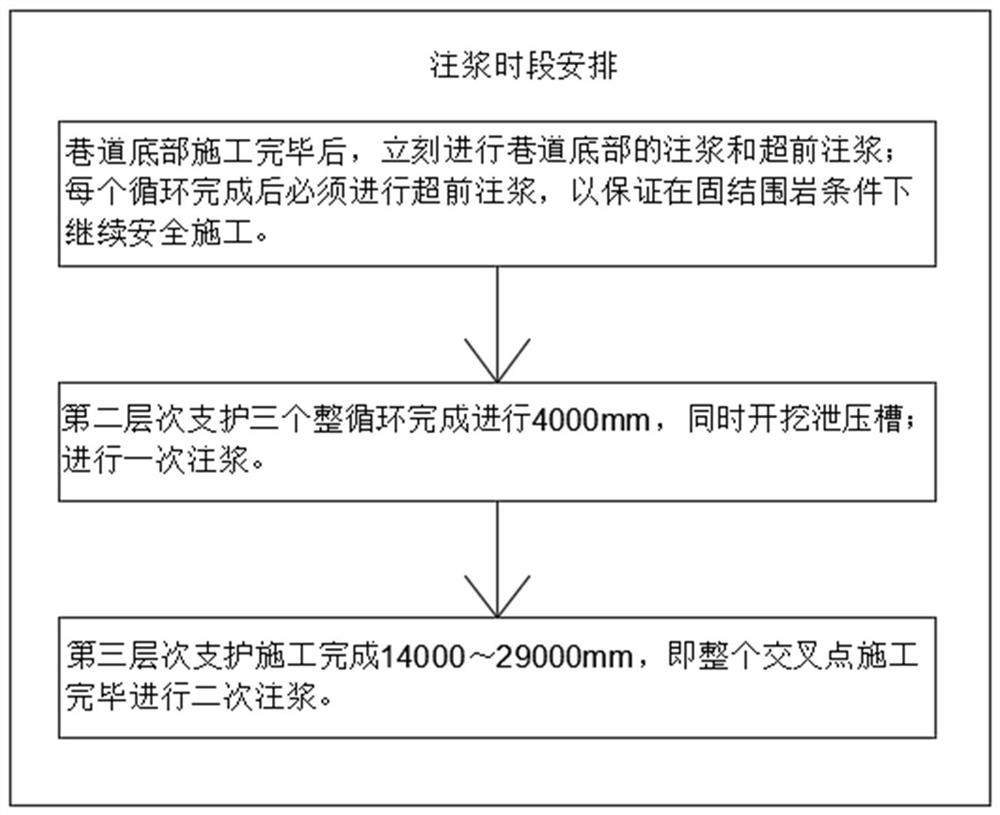

[0024] Such as Figure 1-4 As shown in Fig. 1, a multi-level support technology for roadway with large impact rock pressure, including multi-level support construction process, grouting time arrangement and grouting construction process.

[0025]The construction process of multi-level support is as follows: excavate the barren section, clean and strip the dangerous stones in the roadway, spray 100mm thick concrete on the inner wall of the roadway, and then lay ordinary top bolts on the roadway, and then install the anchor rods driven into the rock mass. Put up the hanging rope and the upper tray, spray 100mm thick concrete on the inner wall of the roadway and drill the grouting anchor hole, install the grouting anchor in the grouting anchor hole just made, the installation angle of the grouting anchor is in the upper semicircle The roof and rock bedding should be vertical, and should be evenly arranged according to the roadway arch circle and the grouting bolt spacing requirem...

Embodiment 2

[0032] Such as Figure 5 As shown in Fig. 1, a monitoring method for the multi-level support process of roadway with large impact rock pressure, including the monitoring process during roadway construction and the monitoring process after construction. By observing the roadway, the deformation of the roadway and the working status of the anchor can be grasped , to verify or optimize the support design to ensure the safety of the roadway support, the roadway convergence deformation and bolt force observation should be carried out during the primary support, and the convergence deformation observation should be carried out during the entire service period of the roadway after the secondary support , monitoring and monitoring is an important link in the whole process of dynamic support and dynamic management. Under the monitoring and monitoring conditions, it is controlled to implement timely dynamic pressure stabilization and pressure-retention grouting in the changing surroundin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com