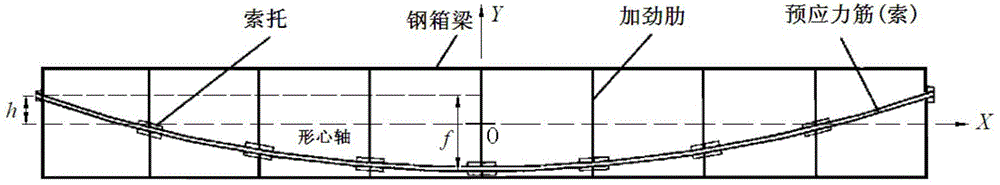

A Method for Optimizing Prestressed Tendon Alignment of Simply Supported Steel Box Girder

A technology of prestressed tendons and steel box girders, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as instability, structural cracking, bridge diseases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

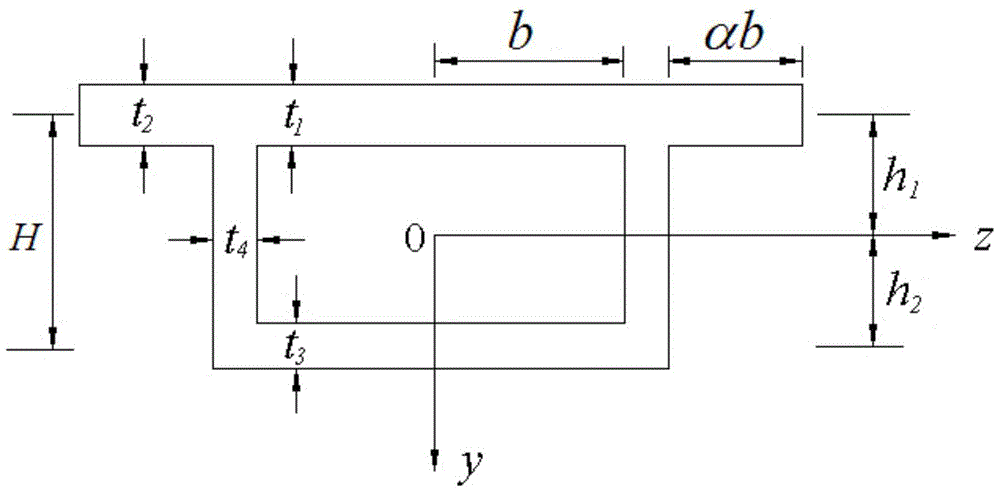

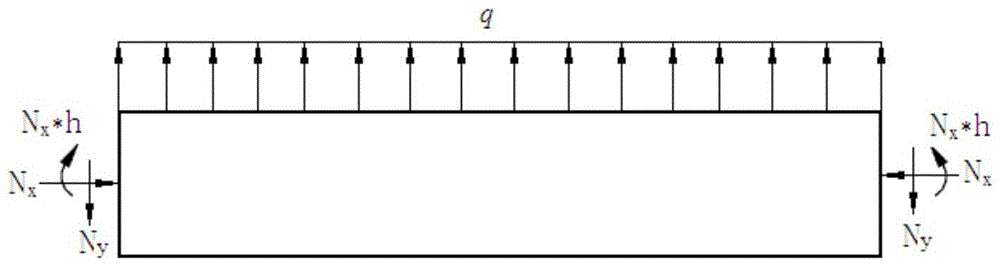

[0051] Embodiment 1: as figure 2 , Figure 5 As shown, the geometric parameters and material parameters of the steel box girder are: t 1 = t 2 = t 3 = 3 mm; t 4 =4mm; b=0.25m; αb=0.25m; H=0.4m; L=5m; E=2.01×10 5 Mpa; G=7.9×10 4 Mpa, and the prestressing force of each prestressing tendon is 50KN, where E 1 ;F 1 ;G 1 and E 2 ;F 2 ;G 2 are stress measurement points or calculation points, respectively. Finally, according to the applied prestressing force and different reinforcement methods, different pre-camber and different flange stress distribution forms can be obtained, and the optimal prestressed tendon layout line can be obtained accordingly.

[0052]The main purpose of the arrangement of prestressed tendons is to make the bridge structure obtain proper pre-camber and pre-stress, so that the structure has good mechanical properties. The steel box girder is a thin-walled structure with unique mechanical properties. effect, the distribution of the normal stress o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com