A Method for Predicting the Deformation of Aluminum Alloy Thin-walled Components During Machining

A technology of thin-walled components and aluminum alloys, which is applied in the field of machining, can solve the problems of complex machining process, large amount of calculation, and prediction of machining deformation, so as to optimize machining parameters, accurately predict deformation, and reduce calculation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

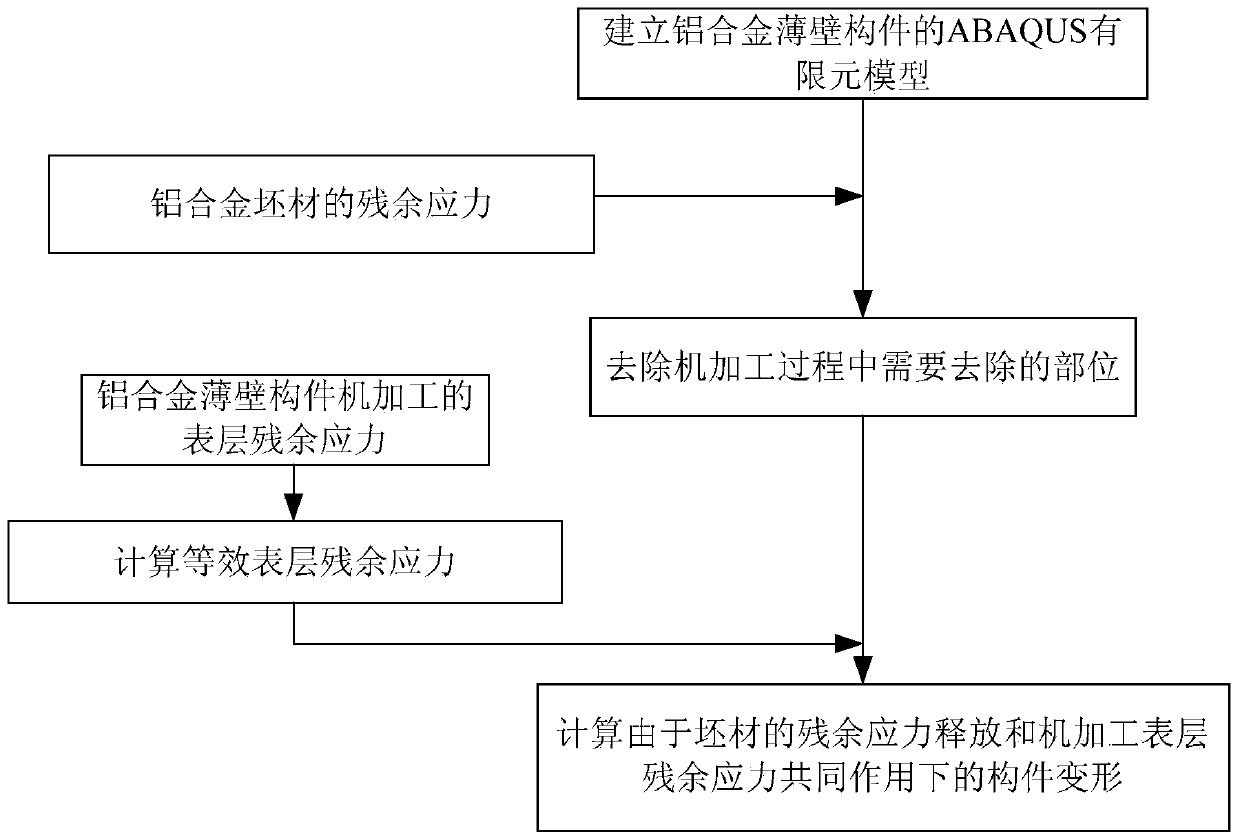

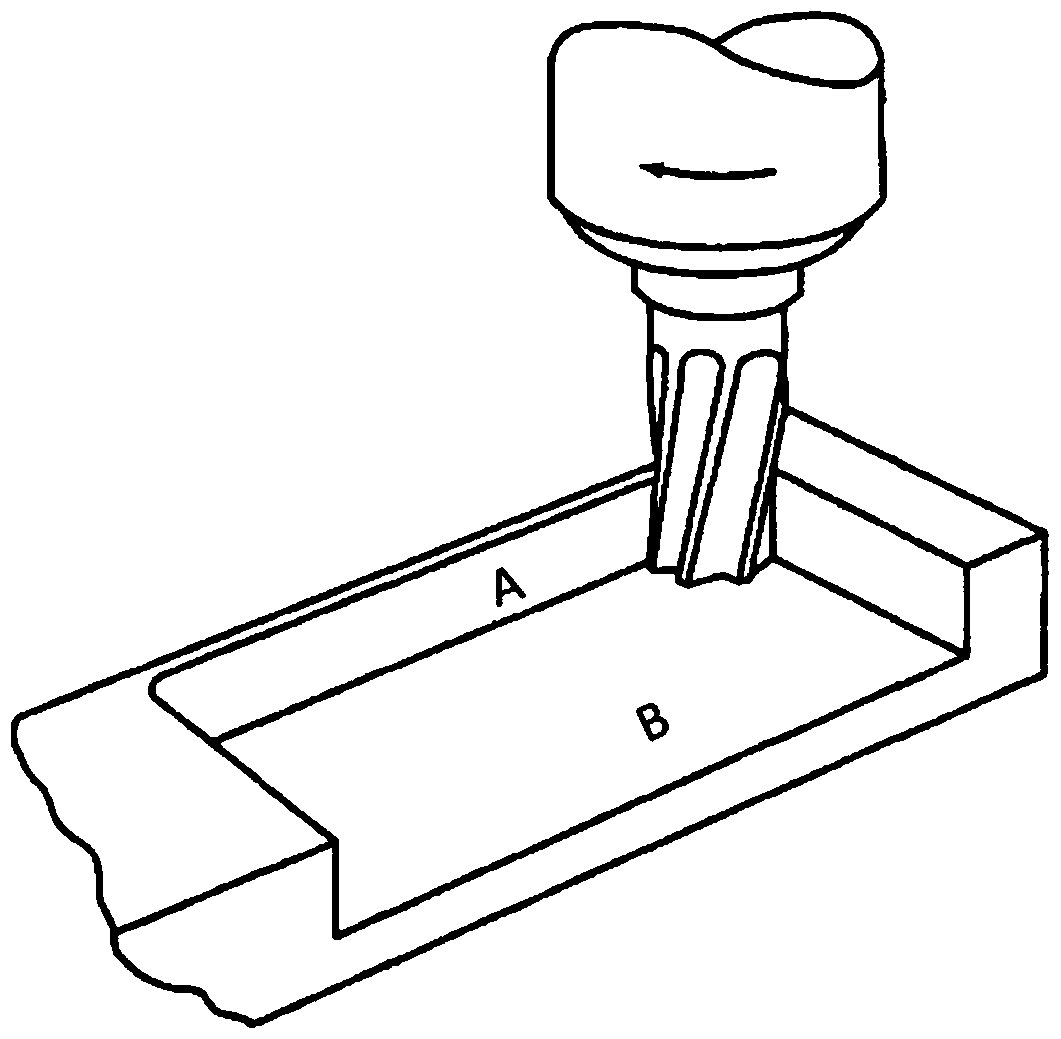

[0032] Specific implementation mode one: refer to figure 1 Specifically explaining this embodiment, a method for predicting the amount of deformation produced by machining an aluminum alloy thin-walled component, the method includes the following steps:

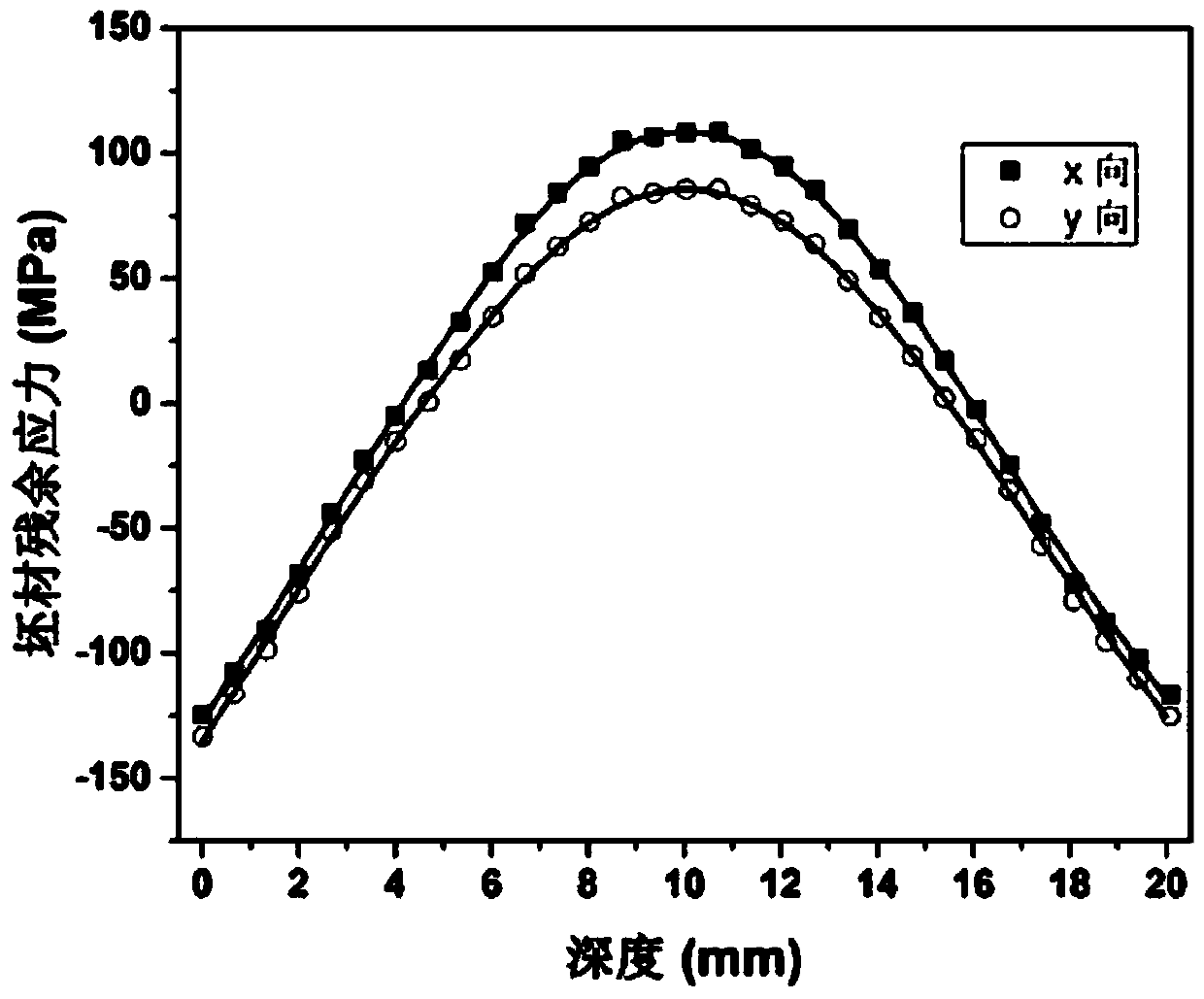

[0033] Step 1: Using the crack flexibility method to test the residual stress of the aluminum alloy billet, obtain the distribution of the residual stress of the aluminum alloy billet along the depth direction, and fit the distribution of the residual stress;

[0034] Step 2: using the XRD (X-ray diffraction) residual stress test method to obtain the distribution of the surface residual stress along the depth direction of the machined aluminum alloy thin-walled component, and to fit the distribution of the surface residual stress;

[0035] Step 3: Replace the fitted surface residual stress distribution obtained in step 2 with the new surface residual stress σ, that is, the distribution of the equivalent surface residual stres...

specific Embodiment approach 2

[0044] Specific embodiment 2: This embodiment is a further description of the method for predicting the deformation of aluminum alloy thin-walled components described in specific embodiment 1. In this embodiment, the distribution of residual stress in step 1 The fitting is realized by the Legendre function;

[0045] The Legendre function is:

[0046]

[0047] In the formula, z' is the normalized depth;

[0048] The distribution of the residual stress σ' along the depth direction of the aluminum alloy billet is fitted as follows:

[0049]

[0050] where A i is the fitting coefficient.

specific Embodiment approach 3

[0051] Specific embodiment three: This embodiment is a further description of the method for predicting the deformation of aluminum alloy thin-walled components described in specific embodiment one. In this embodiment, the residual stress distribution of the surface layer in step two The fitting of is realized by Lagrangian polynomial function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com