Passive cooling system for retention of melts in serious accident state of reactor

A passive cooling and severe accident technology, applied in reactors, cooling devices, nuclear power generation, etc., can solve problems such as poor applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

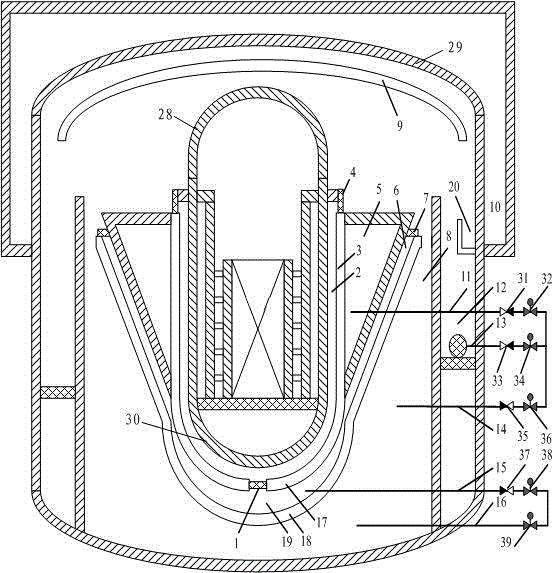

[0027] Such as figure 1 The shown passive cooling system for molten matter retention under severe reactor accident state includes pressure vessel annular cavity water inlet 1, pressure vessel annular cavity 2, pressure vessel annular cavity wall 3, pressure vessel annular cavity steam exhaust hole 4, Annular cavity pool 5, pool annular cavity 6, pool annular cavity exhaust hole 7, crucible cooling pool 8, steel containment upper pool 10, annular pool drainage pipeline 11, recirculation pit 12, recirculation pipeline 13, crucible cooling Pool water supply pipeline 14, crucible chamber water supply pipeline 15, crucible cooling pool drainage pipeline 16, crucible 18, crucible chamber 19.

[0028] Among them, the pressure vessel annular cavity 2 is formed between the pressure vessel wall surface and the annular cavity wall surface 3, and the pressure vessel annular cavity steam exhaust hole 4 is arranged on the top of the pressure vessel annular cavity 2; the annular cavity water...

Embodiment 2

[0041] On the basis of Example 1, it is also possible to set a condensed water diversion device for more efficient diversion of water vapor on the containment, and a more efficient collection of condensed water collection devices

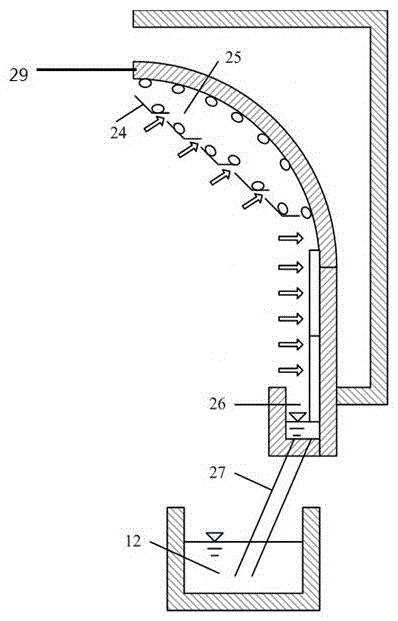

[0042] like image 3 As shown, the condensed water diversion device 9 is installed on the arc-shaped inner surface of the steel containment vessel 29 and is composed of a plurality of guide plates 24 with gaps between the guide plates 24 to form a condensation annular gap 15 with the steel containment vessel 29 .

[0043] The water collection device 20 is installed in the cylinder of the steel containment vessel 29 and consists of a sump 26 surrounding the inner surface of the containment vessel and a diversion channel 27 .

[0044] The working process of the condensate diversion device and the water collection device is as follows: the water vapor in the steel containment spherical head enters the condensation annulus 25 through the gap between the...

Embodiment 3

[0046] On the basis of the above embodiments, the structure of the water inlet hole 1 and the annular cavity exhaust hole 4 of the pressure vessel can be further optimized, so that the water inlet hole 1 and the exhaust hole 4 are only opened when the fluid passes through, and closed at other times.

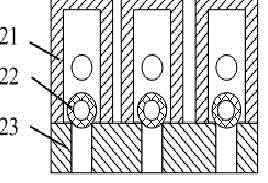

[0047] like figure 2 As shown, the water inlet hole 1 of the annular chamber of the pressure vessel is composed of a punching plate 23 , a guide pipe 21 with holes and an equal amount of hollow stainless steel floating balls 22 . Under normal circumstances, the hollow stainless steel floating ball 22 is still in the guide tube of the punching plate, and the water inlet hole is closed. The guide pipe 21 flows to the annular cavity 2 of the pressure vessel, submerging and cooling the wall surface of the pressure vessel.

[0048] The vent hole 4 of the annular cavity of the pressure vessel is covered by a light floating plate. When the fluid and water vapor in the annular cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com