Wear-resistant halogen-free high-flame-retardant flexible shielding control cable

A control cable, high flame-retardant technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems such as harsh electromagnetic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

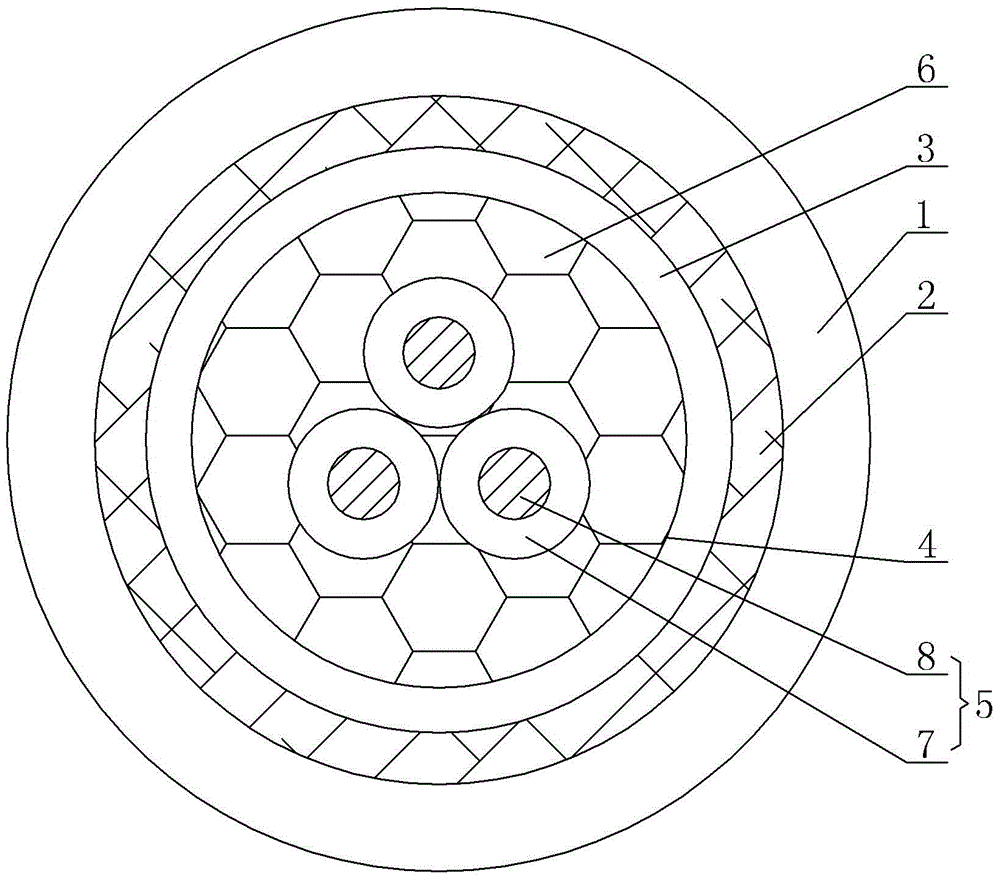

[0013] A wear-resistant, halogen-free, highly flame-retardant, flexible shielded control cable, see figure 1 : including an outer sheath 1, a braided layer 2 and an inner sheath layer 3 arranged sequentially from the outside to the inside with a circular cross section, a central cavity 4 is formed in the inner wall of the inner sheath layer 3, and the central cavity 4 is set There are three core wires 5, which are specifically two power wires and one ground wire. The three core wires 5 are twisted to form an overall structure, and the outer periphery and inner sheath layer of the overall structure are formed after the three core wires 5 are twisted. A number of PP ropes 6 are filled between the inner walls of 3, and each core wire 5 includes an outer insulating layer 7 and a conductor 8 at the center.

[0014] The insulating layer 7 of the core wire 5 is specifically made of modified halogen-free flame-retardant PP material;

[0015] The PP rope 6 is specifically a reinforced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com