Inner guide duct transformer

A transformer and air duct type technology, applied in the field of inner duct type transformers, can solve the problems of affecting voltage conversion efficiency, unfavorable cooling of transformer oil, and low heat dissipation efficiency, so as to maintain heat dissipation efficiency, stabilize heat dissipation efficiency, and improve heat dissipation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

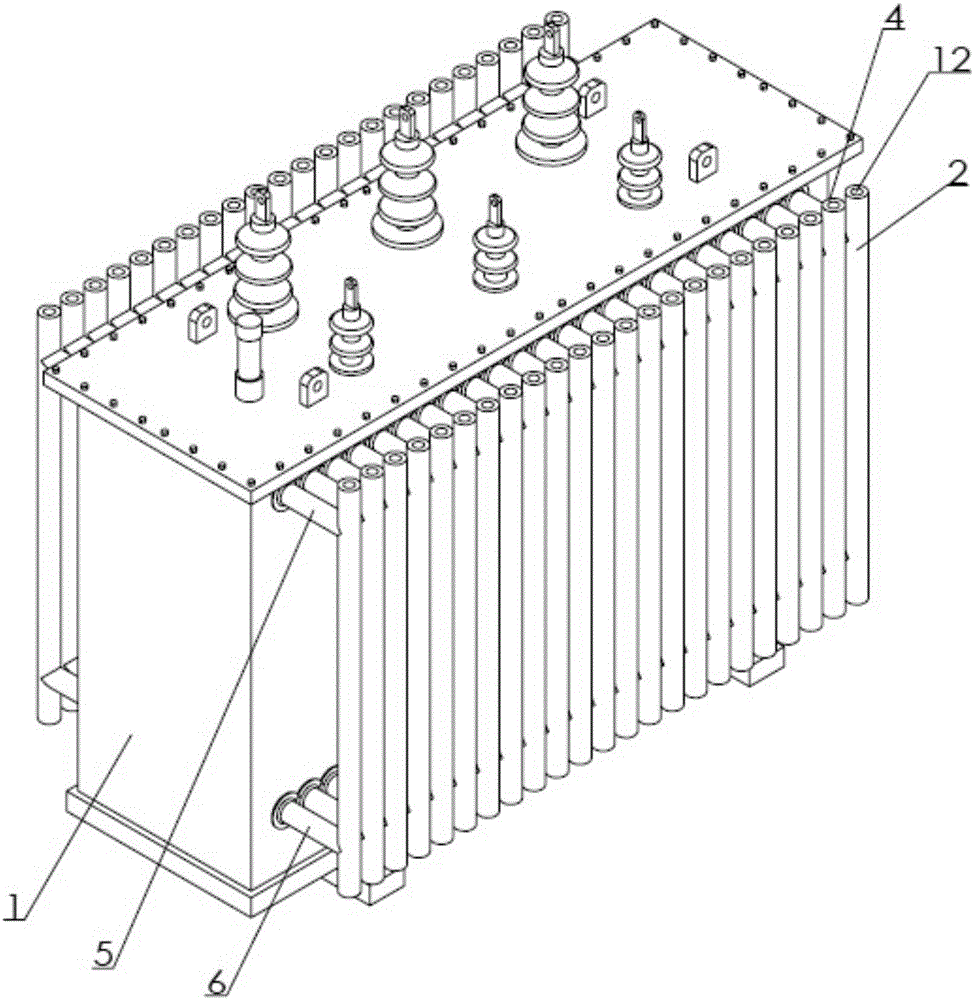

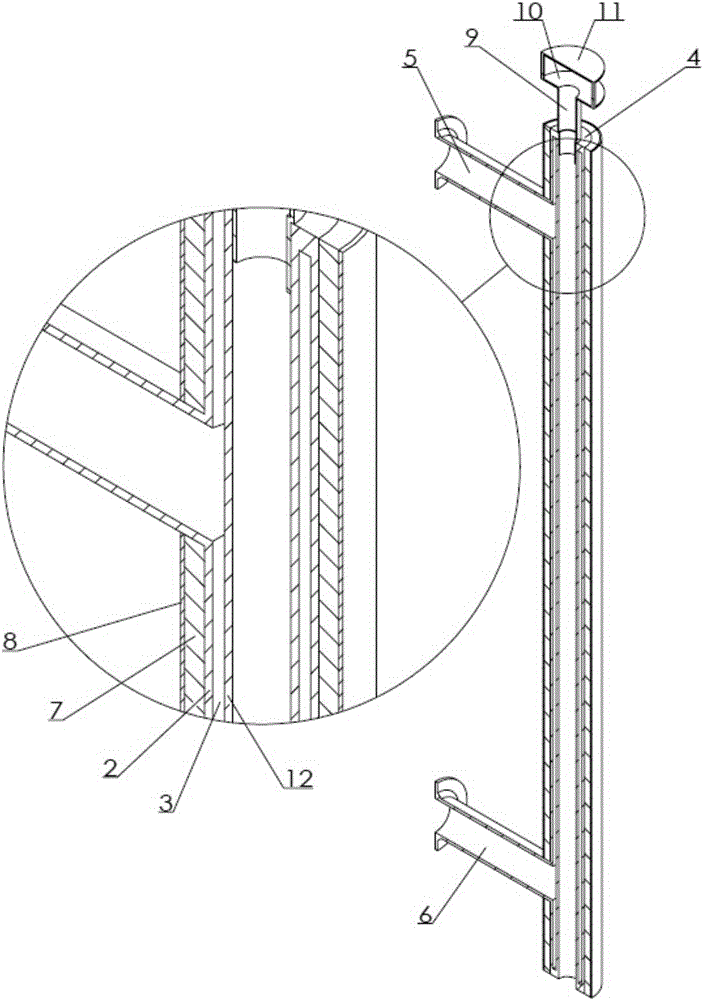

[0013] Embodiments of the present invention are as figure 1 As shown, the inner air guide tube transformer is provided with an oil tank 12 with an iron core inside and filled with transformer oil, and a number of vertical heat dissipation pipes arranged in an array on the side of the oil tank. The heat dissipation pipes are provided with an inner pipe 1, The outer tube 2 is sheathed on the outside of the inner tube. Both the inner and outer tubes are made of thermally good conductor materials. There is a gap between the inner tube wall and the outer tube wall to form an annular flow channel 3. The ends of the inner and outer tubes of the flow channel The head is provided with a plug 4, the upper end of the outer pipe is connected with an upper communication pipe 5 communicating with the annular flow passage, the lower end of the outer pipe is connected with a lower communication pipe 6 communicating with the annular flow passage, and the upper communication pipe communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com