Smoke evacuation apparatus during welding

A technology of smoke exhaust device and smoke exhaust pipe, which is applied in the direction of capacitor manufacturing, electrical components, capacitors, etc., can solve the problem of no smoke exhaust device, etc., achieve the effect of simple operation, simple and fast operation, and improved condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

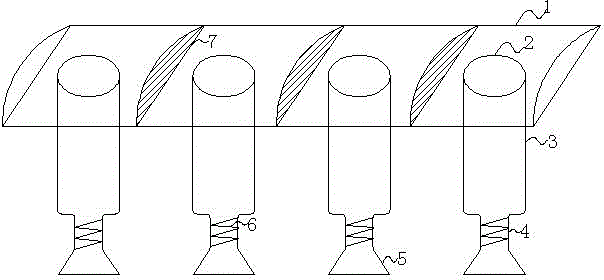

[0012] Such as figure 1 As shown, the present invention includes a smoke exhaust pipe 1 with one end closed and the other end connected to the fan. The bottom surface of the smoke exhaust pipe is rectangular, and the upper surface is arc-shaped. The bottom surface of the smoke exhaust pipe is provided with a number of evenly distributed ventilation openings 2. The ventilation opening is connected with a guide channel, and the guide channel includes a straight pipe section 3 communicating with the ventilation opening, a condensation pipe section 4 located at the end of the straight pipe section, and a tapered air inlet 5 fixed at the end of the condensation pipe section. The condensing pipe section shrinks the diameter of the straight pipe section and is connected with the straight pipe section and the tapered air inlet in a circular arc transition, and the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com