Load adaptive current peak limited power tube connection method

A technology of current peak and power tube, which is applied in the real-time control of power tube turn-on speed and the field of power tube drive circuit, which can solve the problem of large current peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

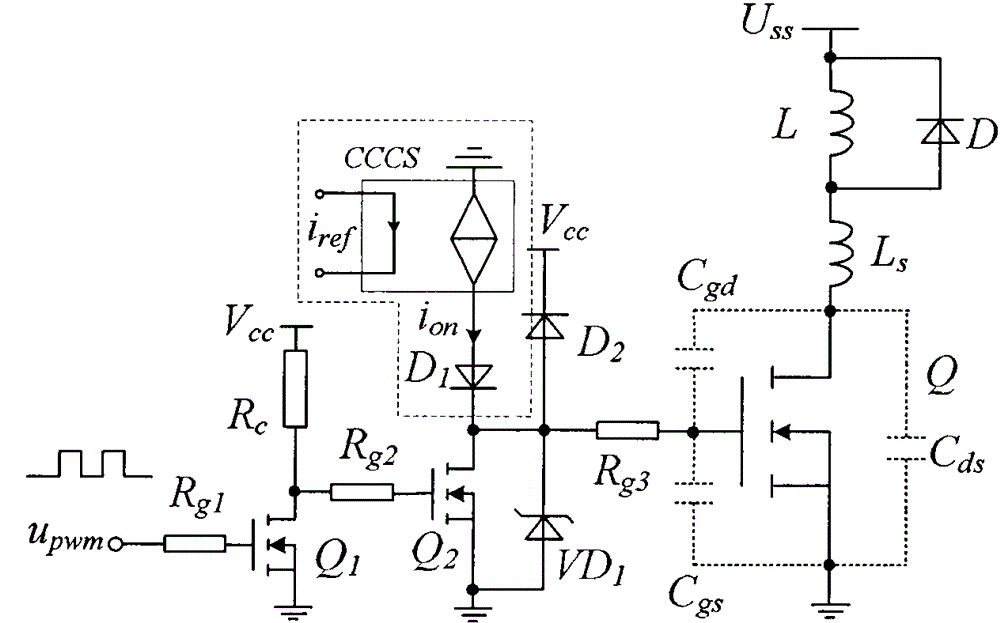

[0029] The present invention will be further elaborated below with a specific example, and the technical scheme is attached Figure 9 Shown, but not limited to the technical solution of the present invention.

[0030] attached Figure 9 It is a load-adapted peak current-limited power tube turn-on speed-controlled Boost high-frequency DC converter, which includes four parts: (1) Boost DC converter; (2) average current control circuit; (3) turn-on Speed control circuit; (4) drive circuit.

[0031] The (1) Boost DC converter is a non-isolated high-frequency DC converter, which is composed of an input voltage source U in , inductance L, main power switch tube Q 0 , rectifier diode D 0 , the output filter capacitor C o , load resistance R L , current sense resistor R s and the voltage sense resistor R 1 and R 2 composition.

[0032] The input voltage source U in The positive pole of the inductor is connected to the left end of the inductor L, and the input voltage sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com