Stacked Inductors

By adopting a configuration of spiral coils and electrically insulating non-magnetic layers in the laminated inductor, the problems of inductance value differences and magnetic interference are solved, the manufacturing process is simplified, and the flatness of the DC superposition characteristics is maintained at low loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

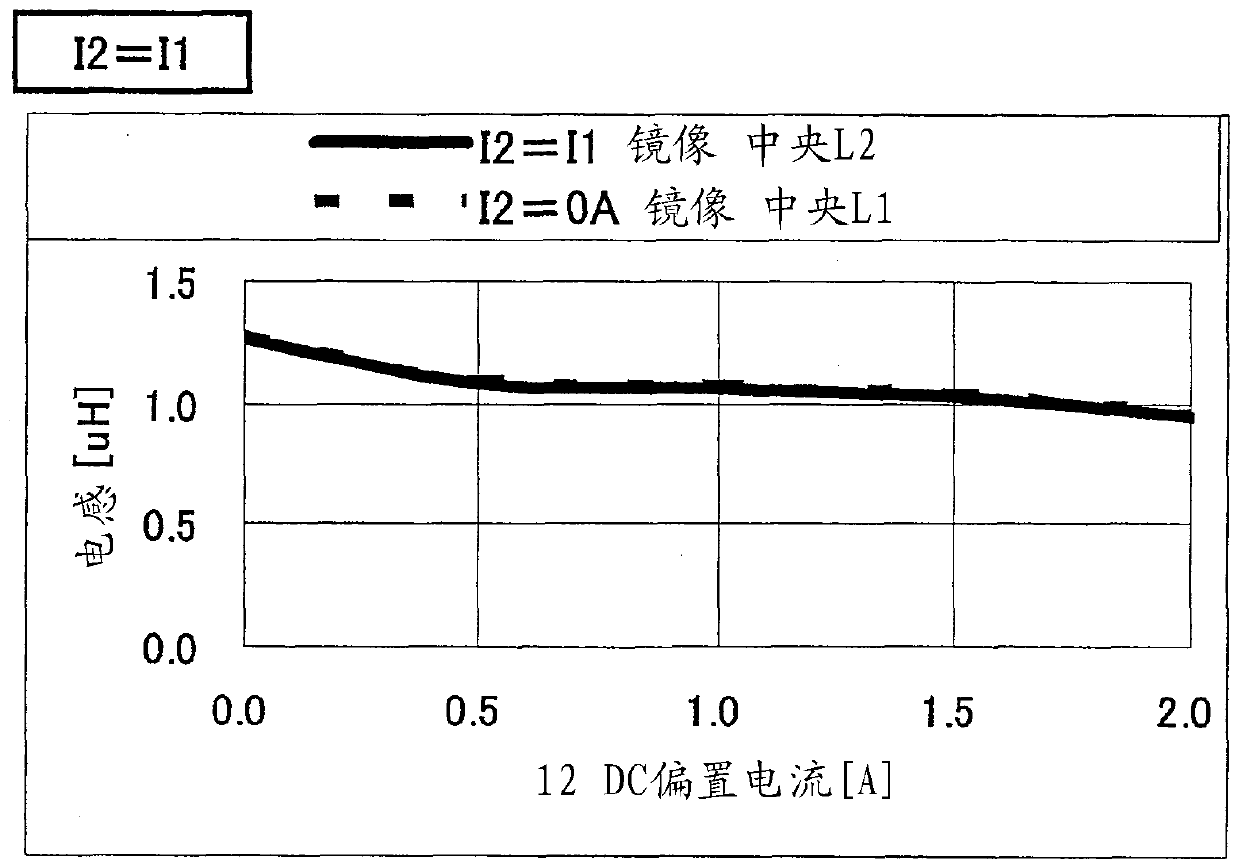

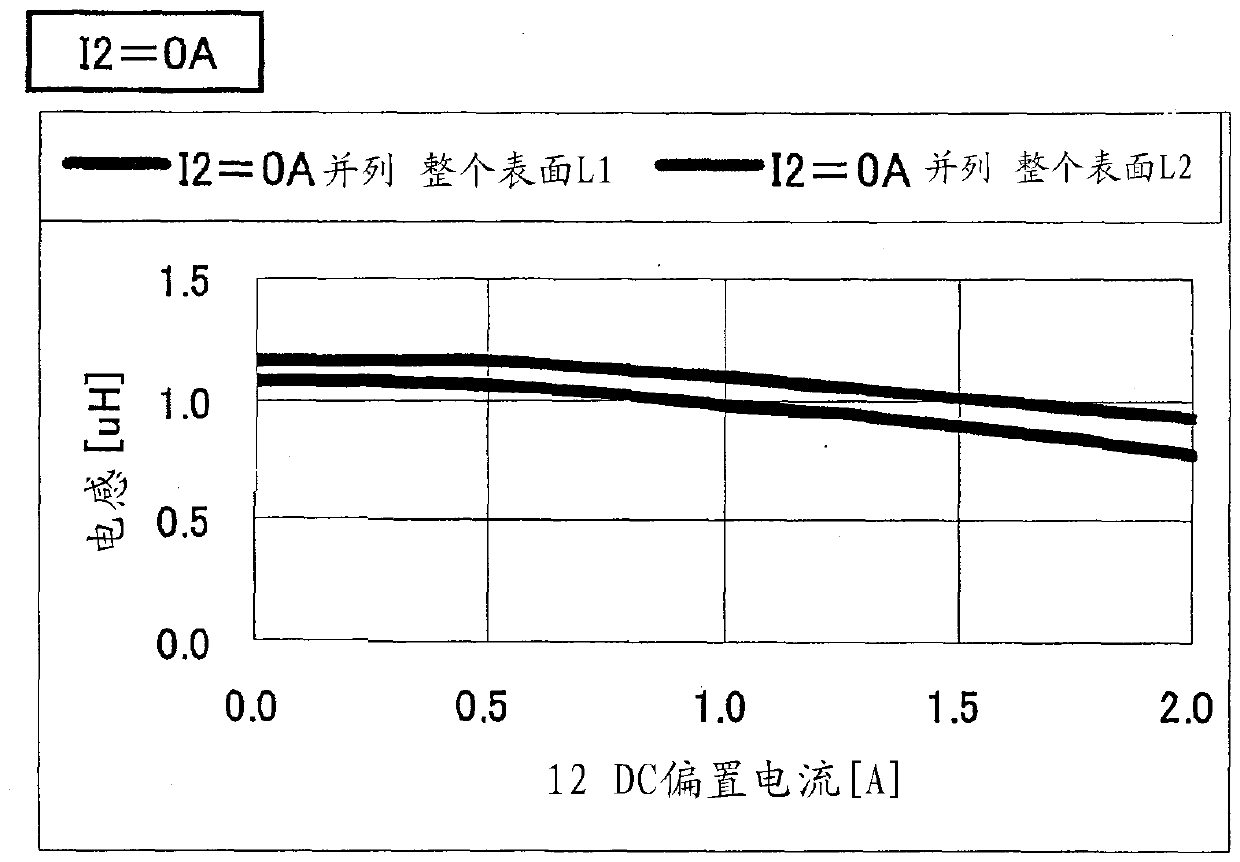

[0050] Figure 1A , Figure 1B , Figure 1C A first embodiment of the laminated inductor of the present invention is shown. The laminated inductor 1 is formed by laminating a plurality of electrically insulating magnetic layers 2 and conductive patterns 3 a and sequentially connecting the conductive patterns 3 a of the layers in the lamination direction. A rectangular parallelepiped inductor in which the coil 3 is spirally wound and both ends 4 of the coil 3 are guided to the outer periphery is connected to a circuit board (not shown) through the end 4 of the coil 3 that is guided to the outer periphery. It is surface mounted on a land.

[0051]Then, in the multilayer inductor 1 of the present embodiment, in the magnetic layer 2 , two coils 3 having the same number of windings and the same coil diameter within the manufacturing tolerance range are arranged in parallel so that their axes are parallel to each other. Here, the coils 3 are arranged in a mirror-image relationship...

no. 2 approach )

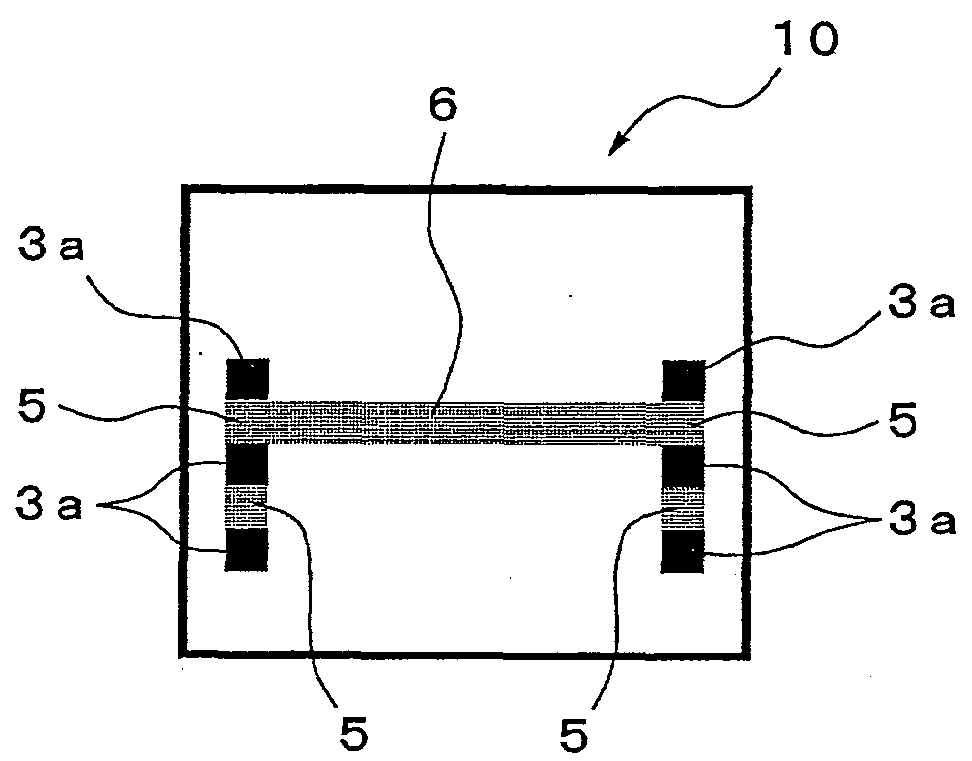

[0056] Figure 2A , Figure 2B , Figure 2C It is a figure which shows the 2nd Embodiment of the laminated|multilayer inductor of this invention. Again, yes Figure 1A~Figure 1C Parts of the same structure shown are given the same reference numerals and their description is simplified.

[0057] In the multilayer inductor 10 of the present embodiment, in the first embodiment, the layer of the non-magnetic layer 6 is formed inside the coil 3 , and the non-magnetic layer 6 and the non-magnetic pattern 5 are further formed outside the coil 3 continuously. That is, in place of the magnetic layer 2 described above, an electrically insulating non-magnetic layer 8 is arranged on the entire surface of the outer peripheral portion 7 where the end portion 4 of the coil 3 is arranged.

no. 3 approach )

[0059] Figure 3A , Figure 3B , Figure 3C It is a diagram showing a third embodiment of the present invention. In the multilayer inductor 20, the non-magnetic layer 6 is continuously formed inside the coil 3 between the non-magnetic pattern 5 between the third layer and the conductive pattern 3a, and, Furthermore, the non-magnetic pattern 5 between the seventh layer and the non-magnetic layer 6 inside the coil 3 and the conductive pattern 3 a is continuously electrically insulated outside the coil 3 , that is, the entire surface of the outer peripheral portion 7 of the end portion 4 where the coil 3 is arranged. In place of the above-mentioned magnetic layer 2, a magnetic non-magnetic layer 8 is used.

[0060] According to the laminated inductors 1 , 10 , and 20 having the above structures, the two coils 3 having substantially the same number of windings and coil diameters are arranged in a mirror-image relationship with respect to the virtual planes between the coils 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com