Corn stalk smashing machine and method for smashing stalks through same

A technology of corn stalks and pulverizers, applied in agricultural machinery and implements, applications, harvesters, etc., can solve the problems of endangering the health of workers, affecting the rotation of flying hammers, and spreading them evenly by manual work, so as to improve the crushing effect and reduce manpower depletion, accelerated decomposition and decay effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

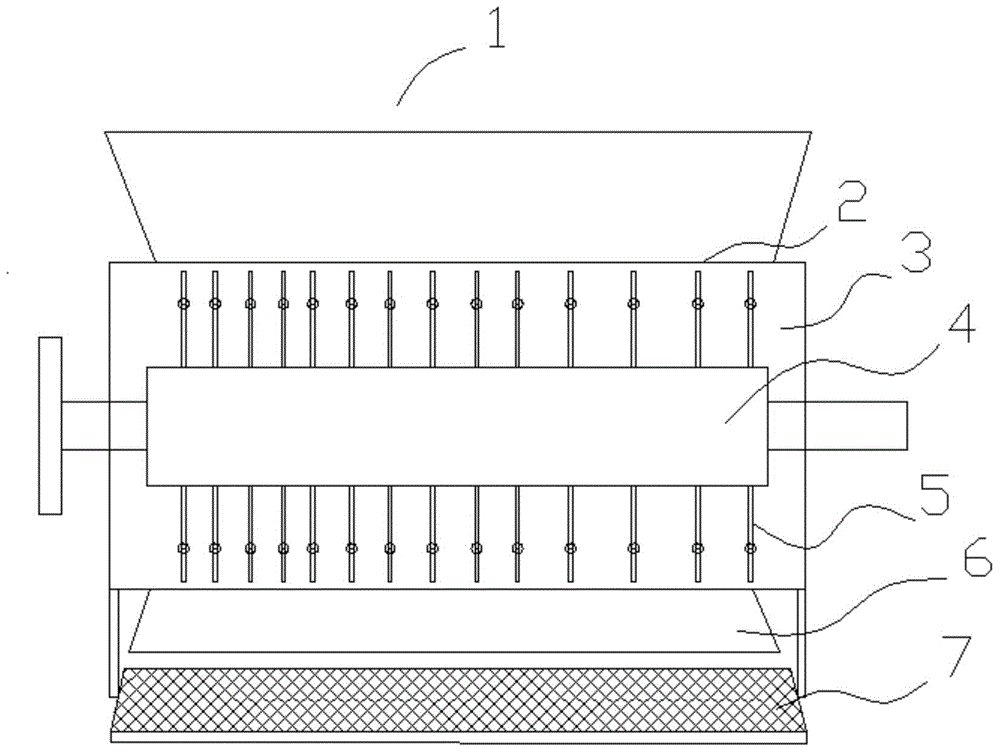

[0038] like figure 1 Shown, a kind of corn stalk pulverizer comprises:

[0039] A shelf; it provides support for the crushing unit and the vibrating bed 7, and the vibrating bed is hung below the shelf.

[0040] Pulverizing unit, it comprises shell 2 and cutter, and wherein said shell 2 is horizontally arranged on the shelf, and the two ends of described shell 2 are closed, and internally forms crushing chamber 3; Described cutter comprises roller 4, first knot And the second knot 5, wherein, the roller 4 traverses the crushing chamber 3, the second knot 5 is rotatably hinged on the roller 4, the first knot and the second The knot 5 is rotatably connected, and the first knot and the second knot 5 are rotated under the drive of the roller 4, wherein the first knot is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com